jeffrey.kissel@LIGO.ORG - posted 17:22, Sunday 22 February 2015 (16857)

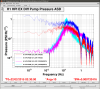

'Final' Change to End Station HEPI Pump Servos has Less Success at Improving Chamber Noise Performance

J. Kissel

While reducing the EPICs sampling rate, and adjusting the servo PID parameters has killed most coupling to the SEI systems at the end stations, in the DOFs that it does remain, there is still a significant amount of coherence. The table below summarizes the remaining coupling:

Freq Coherence

EX Z L4Cs 0.2 - 1 [Hz] ~0.7

T240s 30-150 [mHz] ~0.85

0.2 - 1 [Hz] ~0.7

RZ L4Cs (none -- sensor noise limited)

T240s 40-150 [mHz] ~0.7

HP L4Cs 30-180 [mHz] ~0.85

0.2-0.8 [Hz] ~0.85

T240s (no such sensor)

EY Z L4Cs 70-150 [mHz] ~0.6

0.2-0.9 [Hz] ~0.9

T240s 60-150 [mHz] ~0.8

200-450 [mHz] ~0.9

0.5-0.9 [Hz] ~0.85

HP L4Cs 20-700 [mHz] ~0.9

T240s (no such sensor)

Indeed the coupling looks strikingly like what's left over in the Beam Splitter. I wonder -- since the differential pressure is being measured by sensors right on BSC2 if the measurement of coherence is better than with the rest of the tanks in the corner. In other words, if you measure the differential pressure noise at the tank where your sensors are, you may get a better measurement of the noise coupling.

The pump pressure noise (or the ADC noise) is significantly larger in amplitude at both end stations, and it even appears as though EY isn't getting any suppression at all. Further, because the "SMOO" low-pass filter has been removed, the noise above 100 [mHz] is larger than before. Looking at the HP ASDs, you can see a clear, order of magnitude reduction in the resulting noise in the platform, but at least EY still looks largely dominated by the pump pressure noise between 0.01 and 1 [Hz].

Looks like there's still some commissioning to do on these end station servos. Booooo.

We'll have measure the voltage input noise on the pressure sensors like we've done with the corner station sensor, to make sure this isn't real pressure noise, and if it isn't -- this gives warrant to accelerate the development of an alternative readout system with lower noise. Further, we'll have to see why EY isn't getting any suppression at all.

Images attached to this report

Non-image files attached to this report