Under WP 5527, yesterday I switched the sensors on two of the CS HEPI Pump Skids.

On a Pump Station Skid, see first attachment for a medm depiction, there are pressure sensor ports. 1--right after pump, includes first capacitor accumulator; 2 & 3--after laminar flow resistors & includes accumulator; 4--after final 3u filter. In previous logs, see first plot of 21366, I show that at the corner station, pressure 1 right after the pump is super quiet, again only at the corner. I checked with Barker and we looked at things and there is no reason the trends would be different for these channels.

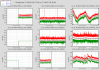

Here the attached plot shows just the four impacted pressure sensors. The first two plots I've zoomed into the quiet portions before and after the switch showing that the "quiet" is tied to the sensor not the channel; the shift in the reading is due to the AOFF (zero) of the individual channel. On the next two graphs (PS4_PRESS1 & 3) I've zoomed into the noisier after and before the sensor switch. Bottom line, the noise level is at the sensor, not the channel. The next two graphs (channels 7 & 8) are the End stations' Pressure1. Clearly EndX is out to lunch with super ugly noise from something we can't figure out. This shows up on the EX control out, CH10, and the servo'd PV (not shown.) The Ch8 graph shows the EY PRESS1 is much noisier than the corner press1s. The last 3 graphs are the control outs for the corner, L0, and EX and EY. Interestingly, despite the much quieter pressure on the CS vs EndY PRESS1s, the CONTROL_VOUTs of the CS and EY are very similar as is their servo'd PVs (the EndY shows the diurnal much more than the others.) Even though the pressure out of the pump is quiet or noisy (CS or EndY) the RC Manifold of the Pump Station makes the signal noisier for the CS. The noise level on the EndY Manifold pressures are about the same or only slightly noisier down the manifold (I looked.)

Still wondering about what is going on...

1) The Accumulator charge on the Press1 volumes are similar although the fluid pressures are different at the three locations. Why? The zero AOFFs are coarse and may be variable over time. The resistances to get to PV setpoint are likely different even at Ends and especially at corner. Why? Different crap in the resistor stacks, different length pipe runs to BSC, more Actuators at corner, different actuators everywhere, etc.

Solution? Be more precise at setting accumulator pressures based on operating pressures? Given the spec'd nominal accumulator charge of 60 to 93% (I shoot for 90%) of operating fluid pressure and the very unlikely(hood) that I would be so good(lucky) at the CS versus the Ends, I'd say this is not the issue.

2) The Corner station has 24 HEPI Actuators per Pump Station while the Ends have just eight. This leads the CS pumps to run about twice as fast as the Ends, see VOUT channels.

I could manually slow down the CS pumps to End speeds and see what that does. HEPI performance likely compromised if not completely hosed but might be informative. Could we introduce additional resistances at the Ends to require the Pump to speed up?

3) Could the laminar flow Resistors be contributing to the down stream noise increase? Does it make sense that the pressure out of the pump is the quietest? This certainly would not explain why the Ends are noisier but might explain the down stream noise.

4) Could the End Station Pumps be cavitating? Yes. I've had a pump cavitate in July, 19699 & 19794, after maintenance in the CS and had to restart it. I did so over 5 minutes and the cavitation stopped. I'd have to mine to find the last time the Ends were restarted and figure out how they were ramped back on. I try to do so slowly manually or with the servo but it's not typically 5 minutes. I don't suspect this as the pump made an audible rumbling when the CS was cavitating and I don't hear this at the Ends. But, maybe there are varying levels of cavitation and there could be benefit to restarting the End Pumps very slowly.

It really does not matter anyway. Given what the servo pressure and control drive look like comparing the CS and EndY, those results are the same. More important and maybe still not that important is to figure out why the EndX pressures are so noisy.

I'll restore the pressure sensor cabling when able and close out this WP.