nutsinee.kijbunchoo@LIGO.ORG - posted 16:43, Thursday 19 May 2016 (27308)

Quick visual inspection of TCS AOMs

Aidan+Alastair (on phone), Bryn, Nutsinee

Quick conclusion:

We are starting to have the same nasty particulates problem that LLO was having up until late April (I assume the problem was somewhat solved there. See LLOalog25658 and many more alogs after this one by Alastair). CO2X is in a better shape (less particulate clumps) compared to CO2Y.

Details:

- Since the LVEA was LASER SAFE and I need to open TCS tables to do this task, I asked TJ (Op on duty) to shut off the green laser shutter. PSL was down but I shuttered the PSL light pipes just in case. All that have been restored.

- In preparation to remove the hoses from the AOM I turned off AOM power supply, shut off both TCS chillers, close the blue pipe valves behine the tables, discconected the AOM quick connects on the tables and then removed the hoses off the AOMs for inspection.

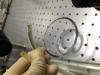

- CO2X: Particulates are not clearly visible until you wipe it with a cloth. No clots visible near the terminate points (quick connects, in and out of the AOM).

- CO2Y: Particulates are clumpy and clearly visible near terminate points. The hoses look worse.

- After the inspection was done on CO2Y table I reconnected the quick connects first instead of the AOM hoses by mistake. A little bit of water was spilled on the table and probably drained down the holes but no damage on the instruments or optics. I had my wipes ready.

- After all the inspections were done, Bryn turned on each chiller on the mezzanine while I watch the table to make sure there was no leaks before I close them out.

- I'll let pictures tell you the rest.

We're going to need a proper procedure on how to resolve this issue. This cannot, and will not, go on until O2.

Both CO2X and Y were restored after the inspection but I don't really like the idea of leaving chillers running after finding these particulates.

Also we don't use DI water for the chillers. We use the same water our PSL is using.

Images attached to this report