peter.king@LIGO.ORG - posted 15:35, Monday 29 August 2016 (29369)

High power oscillator flow sensor related woes

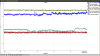

Following on from Jason's log from yesterday (29356). The crystal chiller was engaged without turning the high power oscillator. The flow rates for heads [1-4] were monitored. Every now and then the flow rate for head 4 would drop. Whilst monitoring the flow rates, a trend plot of the relative humidity was generated. It indicated a slow rise in the humidity towards the alarm level of 60%, which from previous experience is the foretelling of a leak. The high power oscillator cover was removed and the insides of the laser was inspected. No signs of a leak were observed. No unusual bulges in the cooling hoses were observed either. The output of the flow sensors for heads 2 and 4 were switched. The signal noise followed the switch in flow sensor, leaving to the conclusion that the output electronics for head 4 was bad. The LM2907-N frequency to voltage converter chip for that channel was replaced with one from an old board (the one closest to the edge of the table, labelled N4). The chip labelled N3 was also replaced due to noise observed in the flow of head 3. Since replacing the chips seemed to have improved the noise situation, the decision was taken not to remove flow sensor 4. The moisture sensitivity level (MSL) of the LM2907-N is 1 according to Texas Instruments, meaning that its lifetime is unlimited provided the relative humidity is less than 85% and the temperature is less than 303 Kelvin. The chips that were replaced happen to be the two closest to the head 3 sensor leak that occurred recently. It is not impossible that these chips got wet when the hose burst, and hence the erratic behaviour since. As an aside, the diode current for diode box 3 went back to reading ~50 A after the flow sensors were reconnected. However since that time it has gone back to reading over 100 A. Jason/Jeff/Peter

Images attached to this report