kyle.ryan@LIGO.ORG - posted 15:40, Sunday 12 February 2017 - last comment - 09:29, Monday 13 February 2017(34074)

2230 UTC -> Filled CP4 (Sanity check!)

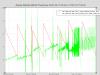

I didn't feel comfortable with the extreme change in fill time for CP4 of late being just the increase in ambient temperature alone. As such, I decided to do another fill at the 48 hr. mark instead of waiting for the nominal auto fill which wouldn't be until Monday (72 hr. mark). Attached is the data. Any chance that we are seeing the needle/seat beginning to show signs of an ice ball obstruction? "I'm just saying!" As shown in the plots, I set the LLCV to 70% open for 30 minutes and then increased it to 100% open. The exhaust temperature finally responded 5 minutes after being increased to 100% open. I went out of the building and cracked the manual bypass valve and personally observed LN2 at the exhaust. I increased the nominal value to 44% from 42%. Note that I also verified that the valve stem pointer does agree with the CDS 4-20 mA output %open values so it isn't like the valve isn't opening etc... Also, the dewar head pressure is ~10 psi, which when combined with the liquid height should be more than adequate to make the elevation "hump" into the 80K pump etc..

Non-image files attached to this report

Comments related to this report

We should recalibrate the device.

Or replace it. Maybe the ice/water did some damage.

Here is a plot over the year showing Dewar level correlated with LLCV setting. We changed the actuator this summer from pneumatic to electronic, and had to apply loctite to the valve stem threads because it kept trying to decouple from actuator stem; the calibration was significantly different from the previous actuator. Looks like LLCV was set to around 44% open during an almost empty Dewar back in Sept. so I think what we're experiencing here is a mismatch of LLCV setting to ambient conditions. Weather plays a big role and because it has been polar vortex cold we didn't have to raise LLCV as much during the winter and now we're back to "norm". We should double check the valve stem to make sure the loctite is still functional.

Images attached to this comment