Kyle, Gerardo, Chandra, John

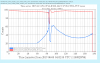

CP4 liquid level control appears to be controlling normally now. The large dip in the red trace is likely due to warm gas in the liquid transfer line being pushed into the pump as the transfer line cools to liquid temperature. This means that the 20% setting was not enough to keep the transfer line cold.

Blue is the control valve position.

The current setpoint is 96%.

It would be nice if DVWEB could provide up-to-the minute data.

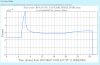

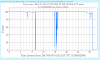

Here is the MY chamber pressure for the last 28 hours as well as the liquid level for the same period. Pressure spike at 5 hours was due to the loss of the ion pump.

The large drops in liquid level are not real - they are due to human actions. The smaller drops to the 80 and 90% range are real and normal as the PID control takes over from manual settings.

Amazing!

This is the result of applying GN2 pressure (40-100 psi) to the clogged sensing line for many days (vs hours that we had tried in the past). We think we melted the blockage with the relatively warm gas. Went through two bottles of GN2 with a few small leaks in fittings.

Happy to close out FRS 6875!

I lowered the %full set point to 92% and LLCV lower limit to 30% open since we think 20% warms the transfer line.