The CP4 enclosure temperature ramp is slowing down and the heater has been running at 100% for the last day. I've been increasing the temp of the GN2 flowing into CP4 so it's not a heat sink. I'm also trying to increase flow by increasing head pressure of Dewar (valve is wide open).

Heaters controls still buggy. Heater ran at 100% all night with no significant increase in air temp. When I visited mid-Y this morning, I found it holding at temperature (setpoint 120C, actual air temps in 90s), so I rebooted the system. Heater now running at 34% and temps recovering (TC#1 reads 81C). New setpoint is 130C with 10C overlimit.

GN2 temp holding steady at 125C. No change yet in head pressure of Dewar after yesterday's change to economizer valve. Flow fluctuates between 30-40 scfhx100.

Bubba turned chiller off to allow VEA to warm up. ![]()

By request from Chandra, I have shut the chiller down at Mid-Y to see if that helps maintain temperature on the bake out. I will continue to monitor the space temps.

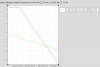

CP4 LN2 consumption is high ~5.4%/day. Three day trend attached, comparing CP4 to CP5. We have a truck delivery scheduled for Tuesday.

Current temps (degC):

TC1: 92.9

TC2: 80.6

TC3: 59.6

TC4: 78.4

GV11 air: 85

Heater output: 41%

GN2 gas regen temp: 124

GN2 pipe temp into enclosure: 85.6

GN2 exhaust pipe temp out of enclosure: <75

RGA valve flange temp: 107

No change on the Dewar head pressure; still reads 12 psig at top and 10 psi next to pressure relief valve

GN2 flow ~ 40 scfhx100

Foreline pressure on turbo has increased from 2.4e-2 Torr to 3.2e-2 Torr since this morning

VEA is warm. Certain areas of enclosure insulation are warm, particularly where the velcro flap overlays the adjacent panel. In some cases the 4" thick panels don't butt up to each other so there are losses through the thin overlap.