Summary

Based on the post-EOM IMC scan results showing significant mode mismatch, we performed a detailed mode-matching analysis using the as-built HAM1 layout. Optics positions were identified from chamber photos, beam traces were reconstructed, and the expected IMC mode-matching and higher-order mode fractions were calculated. The analysis shows that the dominant source of the mode-mismatch degradation is a longitudinal shift of JM2 introduced by the EOM installation, and that moving JM2 can effectively recover good mode matching.

Procedure

- The positions of the HAM1 optics were identified from chamber photos.

- The identified optics locations are marked with purple circles in the attached layout figure.

- Since the JM2 position differs before and after the EOM installation, two circles are shown for JM2 (pre- and post-EOM positions).

-

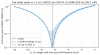

Using these as-built positions, we reconstructed the beam trace and calculated the mode matching into the IMC and the expected 2nd-order mode fraction.

-

This prediction is shown in the first plot.

-

The lensing effect of the EOM was included using the test results from the actually installed crystal (see p12 of slides).

-

-

The measured 2nd-order mode fractions obtained from the IMC scan (reported in the previous post) are overlaid on the same plot for direct comparison.

Notes

- From the reconstructed layout, JM2 is shifted by approximately 2 inches between the pre- and post-EOM configurations.

- Due to the reflection geometry, this corresponds to roughly 4 inches of effective beam path length change.

- This shift is identified as the primary cause of the observed degradation in mode matching after the EOM installation.

- The calculated 2nd-order mode fraction agrees well with the independently measured values from the IMC scan, validating the beam-trace model.

- The model indicates that shortening the total path length by approximately 6.3 inches optimizes the mode matching for 100 W input power as shown in the second plot.

- This corresponds to moving JM2 by about 3 inches, which is feasible within the current layout.

- Around the optimum, a JM2 placement error of ±1 inch degrades the mode matching by only ~1%, suggesting that achieving <1% mismatch is realistic from an installation-accuracy standpoint.

- The third plot shows that, when JM2 is placed at the optimal position, the expected change in mode matching over 0–100 W input power variation is at the ~0.1% level, indicating low sensitivity to power-dependent effects.

Result

- The dominant contributor to the post-EOM mode mismatch is the longitudinal shift of JM2 associated with the EOM installation.

- Moving JM2 is expected to be highly effective in recovering good mode matching to the IMC.

- If JM3 is replaced with a tip-tilt mount in the future, keeping its longitudinal position within ±0.5 inch would be desirable to avoid introducing additional mode mismatch.

Proposal (Practical Implementation)

- Install one iris in the reflected beam immediately after JM3, and place another iris on the IOT2L table.

- Change the longitudinal position of JM2.

- The target position will be documented in a follow-up figure.

- After moving JM2 and roughly passing the beam through the irises, fix the mount using dog clamps.

- Replace the JM2 mirror at this stage.

- Perform alignment using the iris just after JM3 and the iris after the periscope.

- Use JM2 to center the beam on the first iris and JM3 to center on the output iris.

- This procedure is expected to provide sufficient alignment accuracy; if needed, the IOT2 table can be used for further refinement.

- Repeat the IMC scan measurement to confirm the improvement in mode matching.