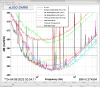

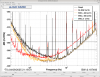

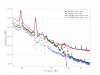

This morning at 16:03UTC, Corey heated up OM2 by setting H1:AWC-OM2_TSAMS_POWER_SET to 4.6, plot attached.

I switched off the heater by changing H1:AWC-OM2_TSAMS_POWER_SET back to 0 count at 21:59:37 UTC.

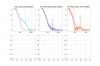

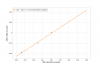

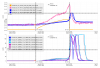

Attached is a plot showing the two thermistors on the OM2 heater (top plots) and kappa C on the bottom right to monitor the optical gain (while doing the darm offset step or before we get to NLN this value is flat as the PCAL line that is used in the calculation is not at its nominal settings).

At 22:00 UTC, Jennie turned this OM2 heater back off.

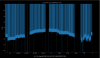

We plan to stay in commissioning until 23:00UTC to avoid contaminating Observing data with the 78618 "bike chain" glitches from OM2 slipping.