Slawek, Betsy, Sebastien, Georgia

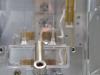

We finished installing the remaining AMDs (AMD 3 and 4) on ETMY this morning. Everything went smoothly, no issue to report. The required force was applied and we observe a nice ring of epoxy around the AMD bases, as expected. The epoxy has to cure 24h with the jig in place (we will remove it tomorrow).

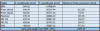

We also inspected AMD1 and 2, installed two days ago. Bond looks uniform, as we observe few fringes between the base and the test mass (Betsy will put pictures later). Find attached a little sketch (not to scale) showing the rough locations of the AMDs on the flats. We will have more precise numbers by looking at the pictures.