[Calum, Rich, Koji]

The crystal of the new EOM was cleaned and re-mounted in the unit. The impedance of the unit after the cleaning was checked. After a few tweaks of the variable components in the matching circuit, decent 50Ohm matching for all the ports have been recovered.

Crystal Cleaning

- All the jobs were done in the optics lab.

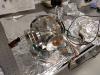

- Made a crystal holding fixture using opto-mechanical components (Attachment 1). Note that a piece of Kapton tape is used to make sure the crystal does not drop.

- Checked the particulates on the optical surfaces with a microscope. The surfaces were named left and right (Attachment 2). There were large number of particulates on the surfaces. (Attachment 3/4)

- Painted FirstContact on the both optical surfaces. We intensionally painted the side of the crystal too so that we can attach a peek tub there for peeling the paint.

- The FC cleaning was pretty effective. It, however, turned out that the assembling of the crystal into the housing cause some dusts atached on the surafaces. This particulates come from the boron nitride used to support the crystal. It is a brittle matrial and emits a lot of dusts.

- So the cleaning was started over again.

- The final cleaning showed excellent dust removal (Attachment 5/6).

- Then the crystal was installed in the housing gently such that the creation of the particulates are minimized.

- The surface observation after the assembly showed sufficiently clean surface, particularly the central area.

Impedance measurement

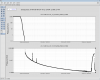

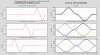

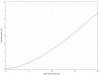

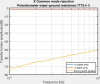

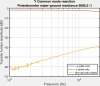

- The impedance of the EOM + matching circuit was measured with a handheld network analyzer.

- The measurements were done before the disassembly (before the cleaning) and after the post-cleaning assembly. (Attachment 7/8)

The impedance measurement after the cleaning showed a slight devitation from the nominal tuning. This deviation was tuned by adjusting the trimmers and the inductor windings.

- The final measurement showed sufficient matching (VSWR<1.5) at each frequency.