S. Aston, Á. Fernández-Galiana, J. Kissel, M. Pirello, T. Shaffer

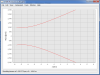

We're still struggling for understanding as to why the H1SUSOPO suspension transfer functions looks like garbage in so many confusing ways.

The message: we're getting closer, but it still doesn't make complete sense -- which means we still can't damp the suspension -- which means we can't just "close it up" 'cause it's "good enough."

Details below.

Attached are an annotated set of .pdfs that summarize the current state of knowledge.

ANNOTATION LEGEND

BLUE / RED:

Stuff with which I’m happy, and I think we should just update the old model.

- Increased the length of the wires from 146 mm to 155 mm. This was an honest mistake in not accounting for the distance between the bottom of the wire clamp and the actual suspension break off point:

% See Wire Assembly D1500483-v3 and

% Wire Pulling Jig Assembly D1500481-v1

% [[D1500485-v2 (0.25in + 1.5in) + D1600451-v2 (3.983in) + D1600462-v1 2*(0.18in) = 6.093 in = 154.76 mm]]

% (was 145.61, but forgot the extra thickness to the *actual* suspension point i.e. the 2*0.18in from D1600462)

> This dead reckoned number then immediately better matched the L, T, and Y

primary resonances without further tweaking needed.

- Increased the blades’ Young’s modulus by only 11% to better match the primary V frequency.

- (The mass remains at 36 kg).

- Updated diagonal MoI’s, Ixx, Iyy, Izz (corresponding to R, P, and Y, respectively)

to better match measured primary R, P and Y frequencies.

> started with Álvaro’s updated Solidworks numbers, and only had to tweak the numbers ~5%.

- Broke out the damping matrix into a value for each DOF (but still a diagonal matrix)

> Used to be all 1.0. Now (L, T, V, R, P, Y) = (0.3, 0.3, 3, 0.03, 0.06, 0.1).

> This nailed the Qs of the primary resonances, and therefore automatically got most of the cross-coupling right.

- Added off-diagonal MoI’s to the parameter file and model.

> Essential to explaining the third resonance in the R and P transfer functions.

> had to do a lot of playing here, but good enough for government work.

> Ixy = 30% lower, Ixz = factor of 10 higher, Iyz = factor of 100 higher.

GREEN:

Unexpected, yet measured, cross-coupling + dubious modeling with which I’m guessing and would love insight. The few physical mechanism I can imagine, but only guess how to model:

- V to Y coupling, or a “corkscrewing”. This, I’d imagined was a sensor or actuator flaw, like the V OSEMs sensing/driving at some angle to the vertical axis. A little implausible, because they’d have to all be cocked in the same direction. I modeled this by adding a V to Y component to the stiffness matrix, but I have now idea how one should really do it.

- T to Y coupling. Here, the mechanism I imagine is a little more plausible: a ~5 mm offset from the transverse actuation plane (TAP) and the horizontal CoM would create a yaw torque. I’m a little more confident in adding that term to the stiffness matrix, because it’s a similar effect to what Álvaro already has in the model to create the “standard” (Longitudinal to Pitch) and (Transverse to Roll) coupling. BUT — if that TAP offset exists, there’s no reason to think an LAP doesn’t exist.

ORANGE / PURPLE:

Stuff I still have no clue how to explain.

THINGS WE'VE RULED OUT IN HARDWARE

- TJ promises that the H1SUSOPO is not rubbing, but continues to question whether he can really tell given the poor visibility and tight quarters in chamber. I've told him to hold off checking again until we can get the HAM6 ISI balanced, floating and damped. That might at least get rid of some of the incoherent noise.

- TJ, Alvaro, and myself have all gone over the OSEM2EUL and EUL2OSEM basis transformation matrix math, and it all seems to check out. See the "other files" of G1701821.

- After consulting with the analog CDS team project-wide, we identified that the OPOS is the last hold-out using -v2 of the HAM-A coil driver D1100117, which has lower output impedance, and thus increasing the transconductance from v3 by a factor of 10. Every other SUS that uses the HAM-A driver (HAUX and HTTS) have had their impedance increased, as per ECR E1201027. This explains some of the discrepancy between the model L1's measurement, but it doesn't explain why H1 is all over the map.

- Hearing this, (and remembering the jumper issues with ZM2, LHO aLOG 40218, and ZM1 LHO aLOG 40241), I was suspicious we were driving one-third of the SUS with v2 and two thirds with v3. Even though the chassis were clearly labeled when we got to the racks, Marc was gracious enough to open up the OPOS HAM-A coil drivers so we could see with our own eyes that the output impedance on R33 and R11 were 100 Ohms as expected.

ANALYSIS DOCUMENTATION

Also attached is the model ssmake_voposus.m and RED parameter set, oposopt_h1susopo_fit.m which produced to today's results, which will become obsolete after we merge the stuff we like with the BLUE parameter set oposopt_h1susopo.m, which we'll probably rename to something like oposopt_production once we're happy.

Just to record everything I've been using:

${SusSVN}/sus/trunk/Common/MatlabTools/SingleModel_Production/

comparesingleparams.m << comparison script

ssmake_voposus.m << dynamical model

oposopt_h1susopo.m << BLUE reference parameter

oposopt_h1susopo_fit.m << RED updated parameter set

${SusSVN}/sus/trunk/OPOS/L1/OPO/SAGM1/Results/2018-01-29_0900_L1SUSOPO_M1.mat

${SusSVN}/sus/trunk/OPOS/H1/OPO/SAGM1/Results/2018-02-27_2209_H1SUSOPO_M1.mat

*phew* this is exhausting.