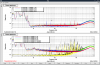

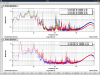

In support of the CP4 bake-out, I've created a temporary Rate-Of-Change (ROC) medm and linked it as the last item on the VE pull-down on the SITEMAP. It is calculating the ROC for a CP3 thermocouple, which is actually located at CP4. When the 1-HOUR measurement exceeds 1.0degC/hour in either direction, the gray rectangle turns RED, indicating a cell phone alarm has been issued.

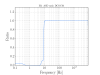

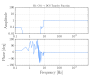

Note, ROC also calculates the LN2 consumption rate of EY-CP7-Dewar as a test channel (consumption is about 1% dewar capacity per day).