Troubleshooting the noise on the HAM6 corner3 CPS, see 42471. Our testing suggested that unplugging either cable from the satellite box improved the noise in the still plugged-in channel. So, the V3 was unplugged for a few hours followed by having the H3 unplugged for several hours. Nominal configuration was restored this morning.

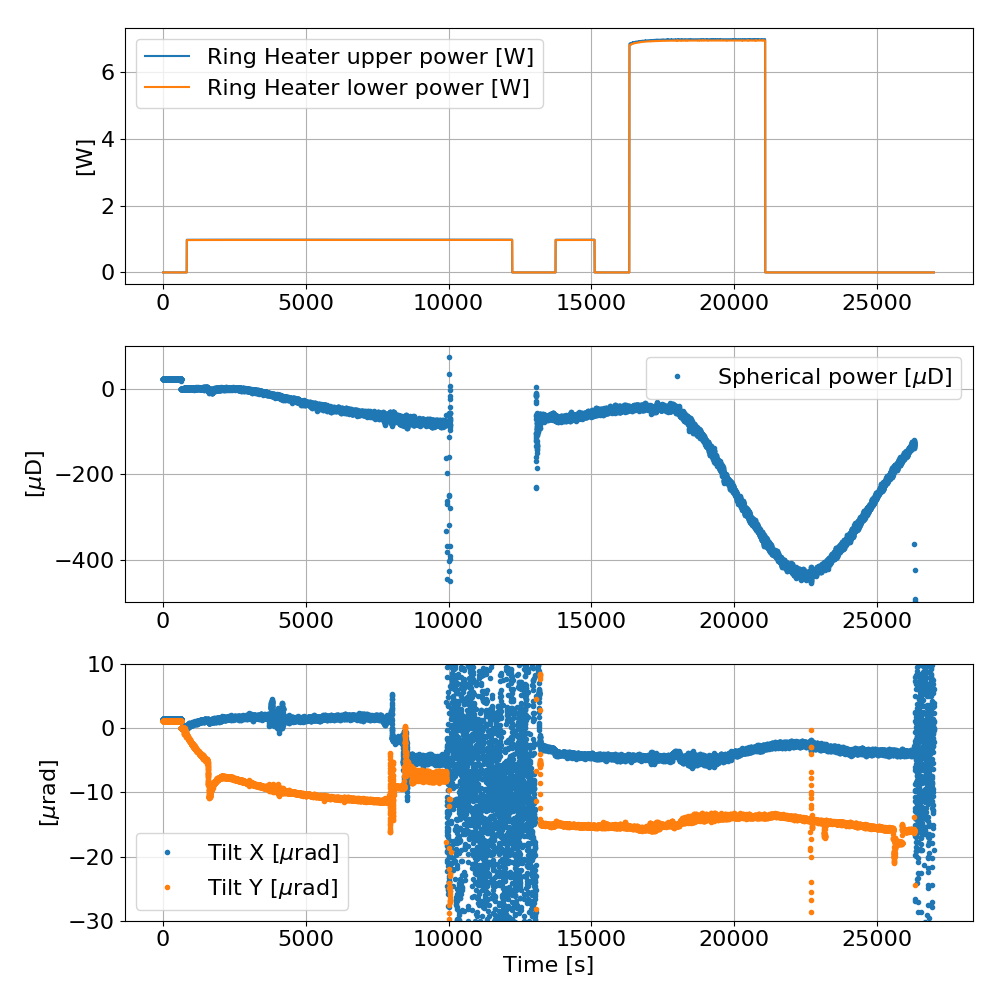

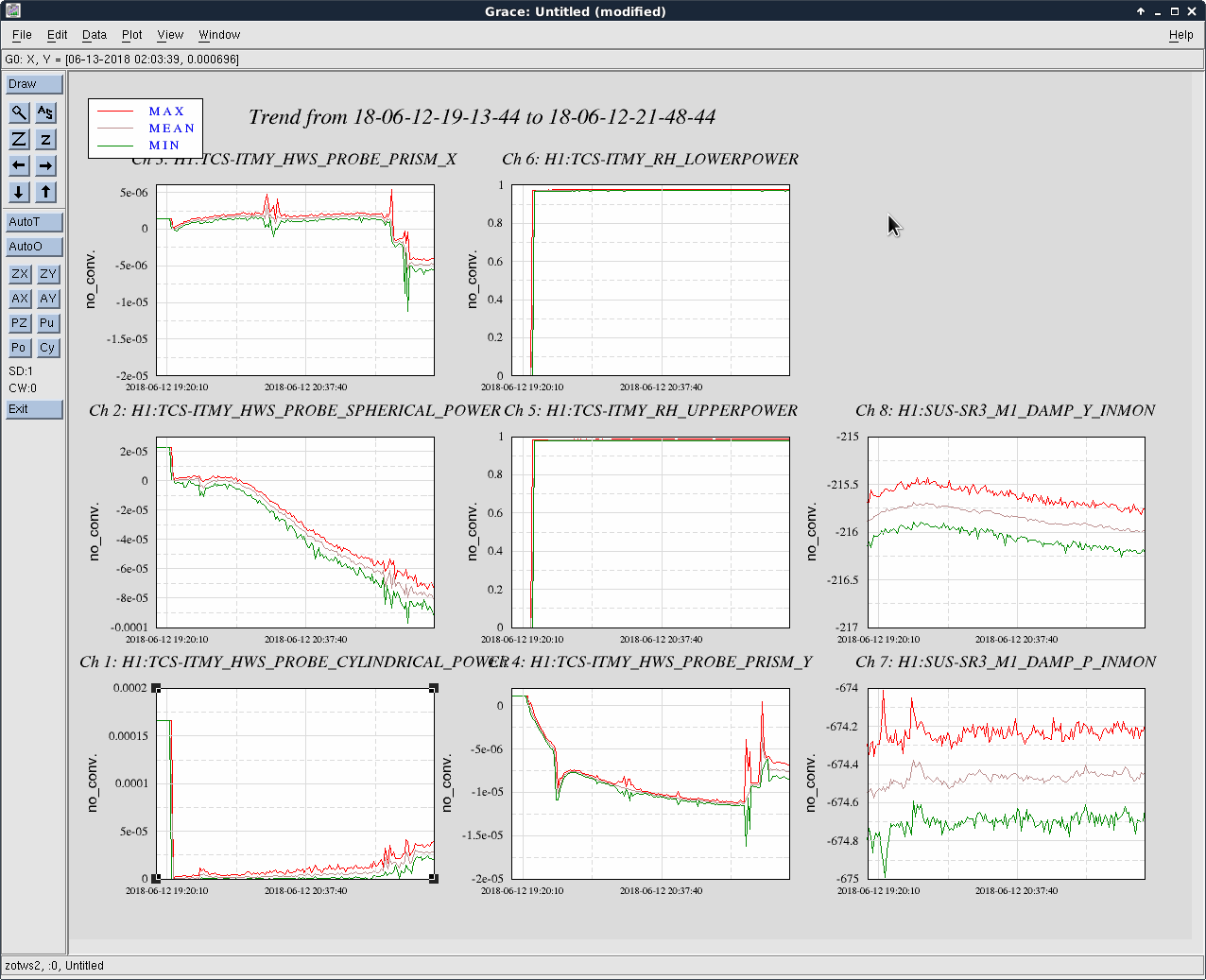

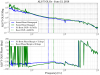

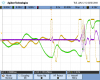

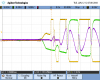

Attached are spectra from these three periods, the platform was damped during these times. The top plot is the current nominal state showing the extreme noise on the corner3 sensors. In the middle plot, the H3 sensor is unplugged and the V3 sensor nicely trends with the other vertical channels. The bottom plot is during the time V3 is unplugged and the H3 signal mostly trends sort of with the other horizontal signals. In both unplugged tests, the remaining corner3 signal still shows higher noise at higher frequencies maybe hinting at the underlying issue.

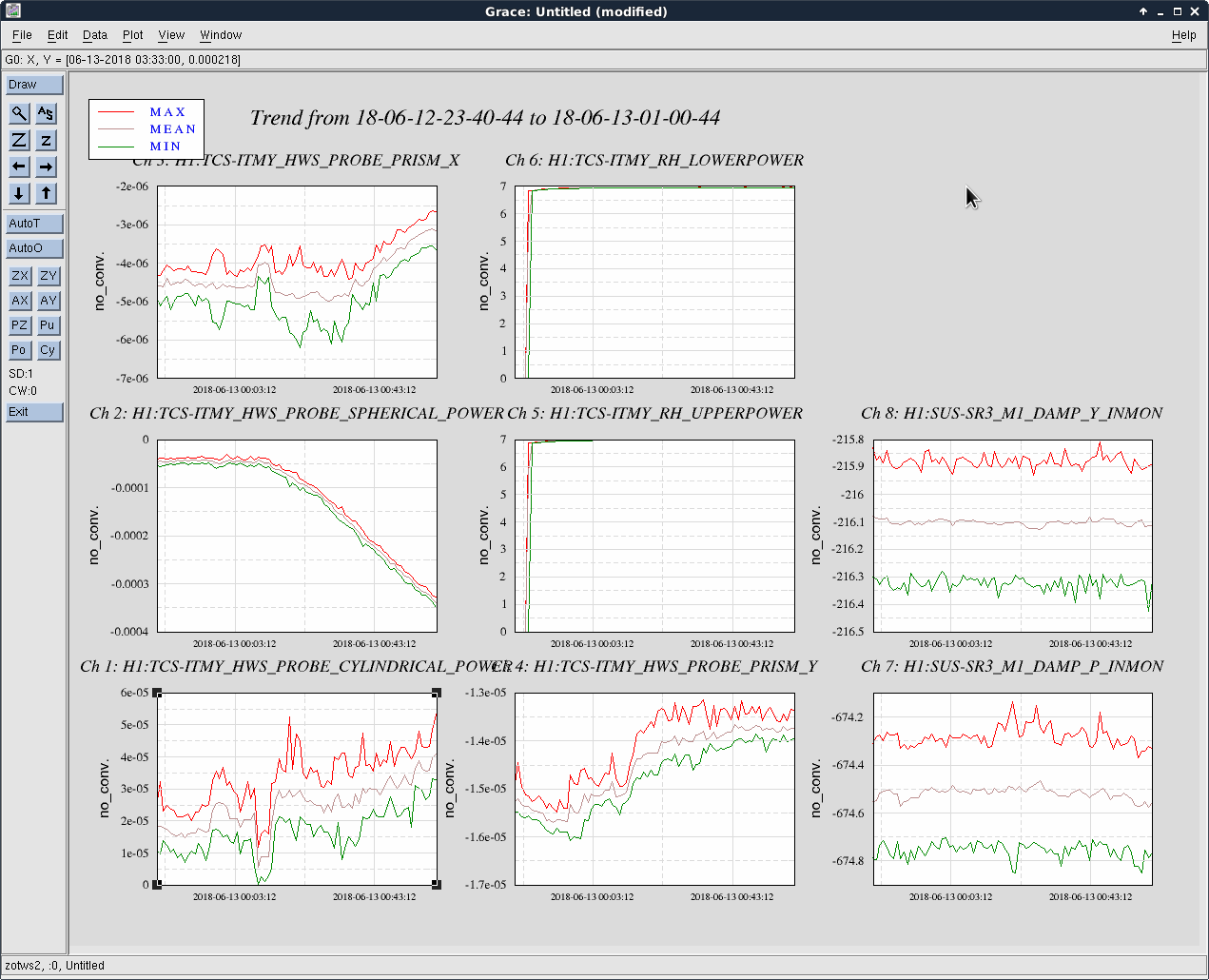

Also looking at the time series, not shown here, the min-max peaks are reduced nearly to pre June 1 levels when one channel is unplugged.

I have a 3IFO request in so as to swap out the crate to see if there is anything in the theory that these results suggest the crate may be the problem. FYI, this is HAM6 and this ISI was built what 10 years ago? Installed and pulled from chamber, some mods made (can't remember what off hand) and then reinstalled. It has been a test piece for many things given its convenient location. Anyway, fodder.

Will Update FRS 10851