Krishna

The new BRS DetChar Summary pages alerted me to a strange noise visible on Jan 19th and Jan 20th.

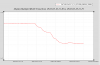

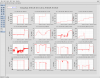

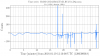

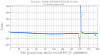

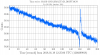

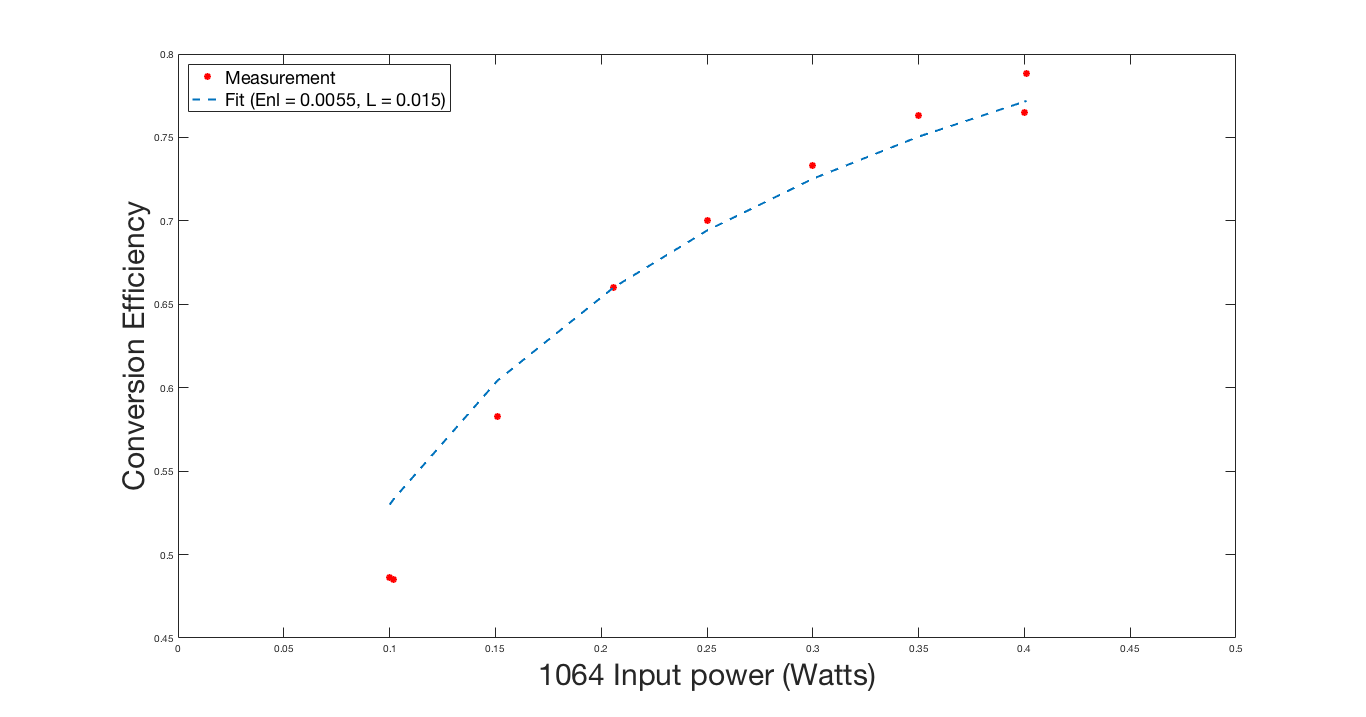

I looked at the rY_in DQ channel and the noise looks like short duration spikes in the angle channel. See first attached plot. The low-frequency oscillation of BRS-X is visible and the spikes start in the 17th minute of the plot. Zooming in (next plot), these spikes last for 8-10 second and the data resumes it's previous trend, with no apparent offset. I looked at most of the error bits listed in the BRS troubleshooting guide and saw no indication of any kind of hardware issue. I have also attached the DRIFTMON data showing a similar spike but appropriately smaller, indicating that it is a real deviation as seen by the C# code. I looked through two months of recent data and don't see any other similar noise.

I have two theories to explain this:

1. We have a literal bug in the autocollimator - most likely near the CCD. The CCD isn't fully enclosed and there is room for bugs/critters to get in there especially since they are attracted by the heat of the CCD. We had a similar issue some time ago in the lab. Whether or not this is what happened, Michael and I agree we should try to more fully seal the autocollimator so that this never happens.

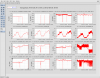

2. The CCD is failing. I think this is less likely since it seems to be functioning perfectly now, even though the code hasn't been restarted since Jan 4. The previous time the CCD malfunctioned (Jan 31), the symptoms were very different (see 4th plot). However, we can't rule this out completely. We need to see if this happens again (after sealing up the CCD), and if needed the CCD can be replaced. It is an off-the-shelf item - Basler Racer raL4096-24gm.