Summary

ALS path on the PSL table was realigned (it was totally misaligned after the main IO path was redone on May 09, alog 41924).

The beam is already going to the SHG in ISCT1 but we need to refine the alignment there. We don't have to go back into PSL to do this work, the rest should be done in ISCT1 in laser hazard some time next week (or earlier when there's an opportunity).

Details

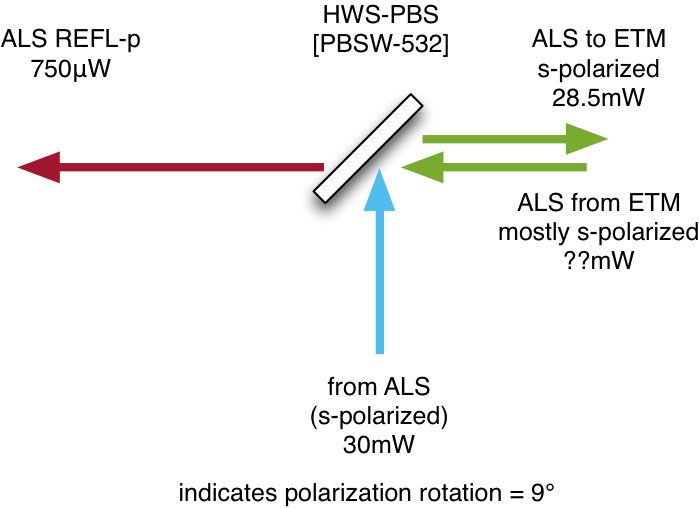

See https://dcc.ligo.org/D0902114 for nomenclature.

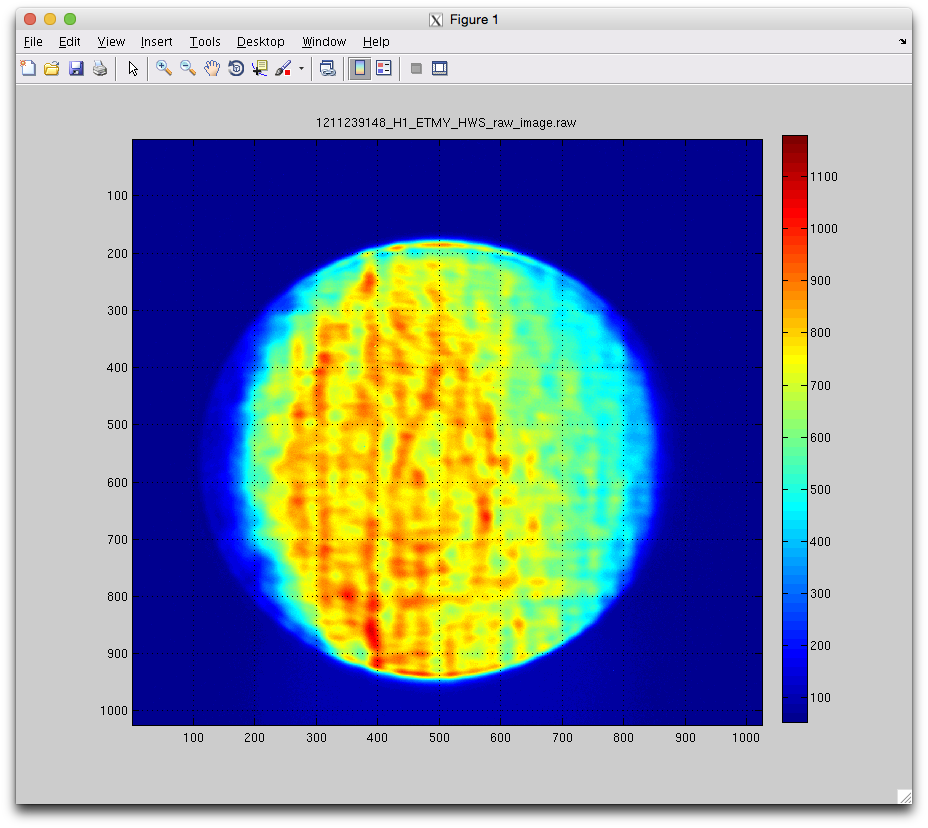

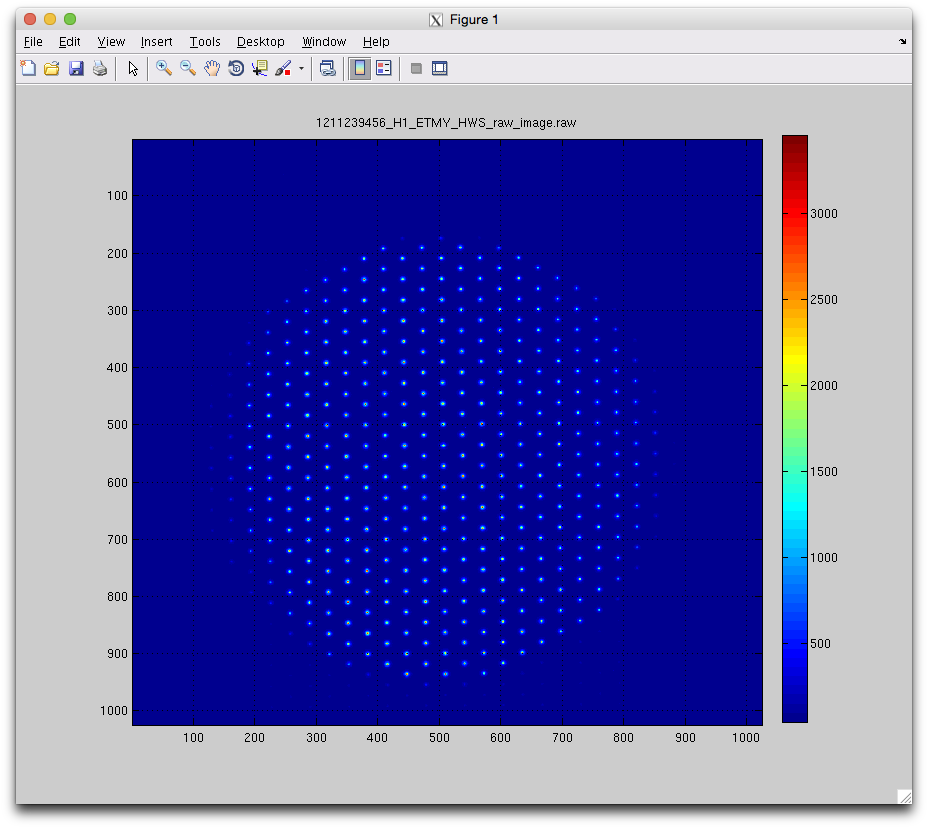

At first the beam was blocked by the Faraday aperture (first attachment). I and Ed used ALS-M1 and ALS-M2 to clear the Faraday and center the beam on two irises between ALS-M3 and the periscope. After we were satisfied, however, Thomas and Dan couldn't find the beam in ISCT1. We also found that the beam was clipping on the top periscope mirror (ALS-M5) on the PSL table though the beam went into HAM1 (first attachment, in this picture two irises are almost closed so it's easier to see the beam position).

Dan found that the beam was already hitting the in-chamber steering mirror, and we regained the beam in ISCT1 by turning the top peri mirror mostly in YAW in the PSL room.

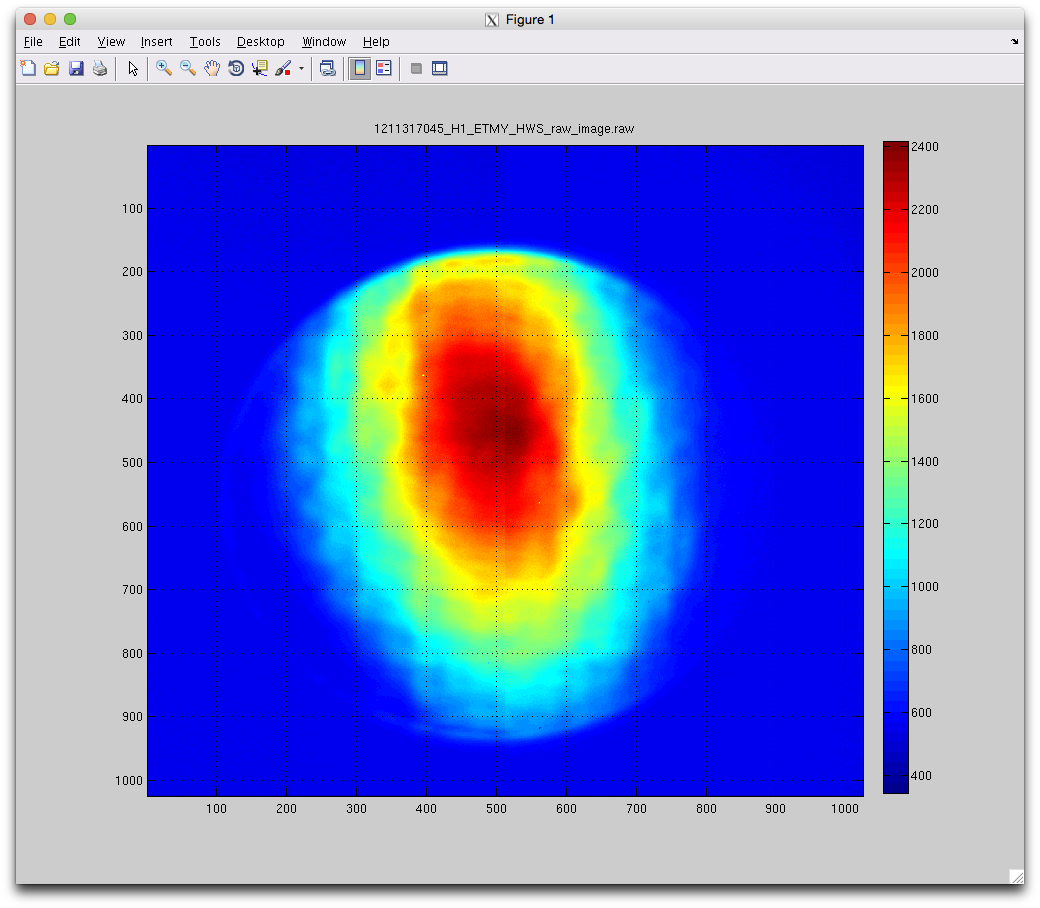

From there on, I tried to use the top (ALS-M5) and bottom (ALS-M4) peri mirror on the PSL table to walk the beam on ALS-M5 while keeping the beam in ISCT1. That worked until the bottom peri mirror hit some hard stop in YAW. There's plenty of actuator threads left, but it seems like the mirror mount and the 45 deg mounting block had a mechanical interference. I ended up using ALS-M3 also. We just stopped doing this when the beam position on the top peri mirror on the psl table was not as terrible as before (attachment 2, same caveat as the first picture). Then we used the ALS-M5 to steer the beam at the center of the bottom peri mirror in ISCT1.

In the PSL room we moved the irises so the beams are centered on them.