Betsy and Travis told us that we can just use the top blade to rotate TMS is we're talking about O(100urad) instead of O(many mrad), so we did just that.

The procedure was: Remove ERM protection cover, adjust EX bias so the optic is centered in oplev, inject green laser, set the TMSX offset to get the retro-reflection on the table. Then loosen the blade (which makes TMS sag so no retro-reflection), turn the adjustment screw, tighten the blade, look where the beam goes, repeat.

It turns out that 1/4 turn of the adjustment screw took out 400-something urad, then Travis tried 1/16 of a turn and that took out the rest.

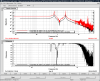

In the end TMSX alignment sliders were set to [P,Y]=[-74,5] urad, almost perfect for Y, and P is no worse than yesterday where it was [91,-585].

We also adjusted BOSEM depth. For F1, LF and RT we recently measured the open values and set the depth (41675) so didn't bother to remeasure open values but we reset the depth anyway as RT seemed to have drifted out.

For F2, F3 and SD, old and new offset as well as open value as of now are:

| |

Open today |

New offset |

Old offset |

Reading before adjustment |

Reading after adjustment |

| LF |

NA |

NA |

-9350 |

~9.9k |

~9k |

| RT |

NA |

NA |

-13475 |

~16k |

~12k |

| F1 |

NA |

NA |

-10515 |

~10.9k |

~10.7k |

| F2 |

18.1k |

-9050 |

-11164 |

~11k |

~9k |

| F3 |

23.2k |

-11600 |

-14150 |

~18.5k |

~11.3k |

| SD |

22.1k |

-11050 |

-14372 |

~11k |

~11.5k |

Inventory info: S/N of F3 BOSEM is 296, F2 301.