Daniel, Nutsinee

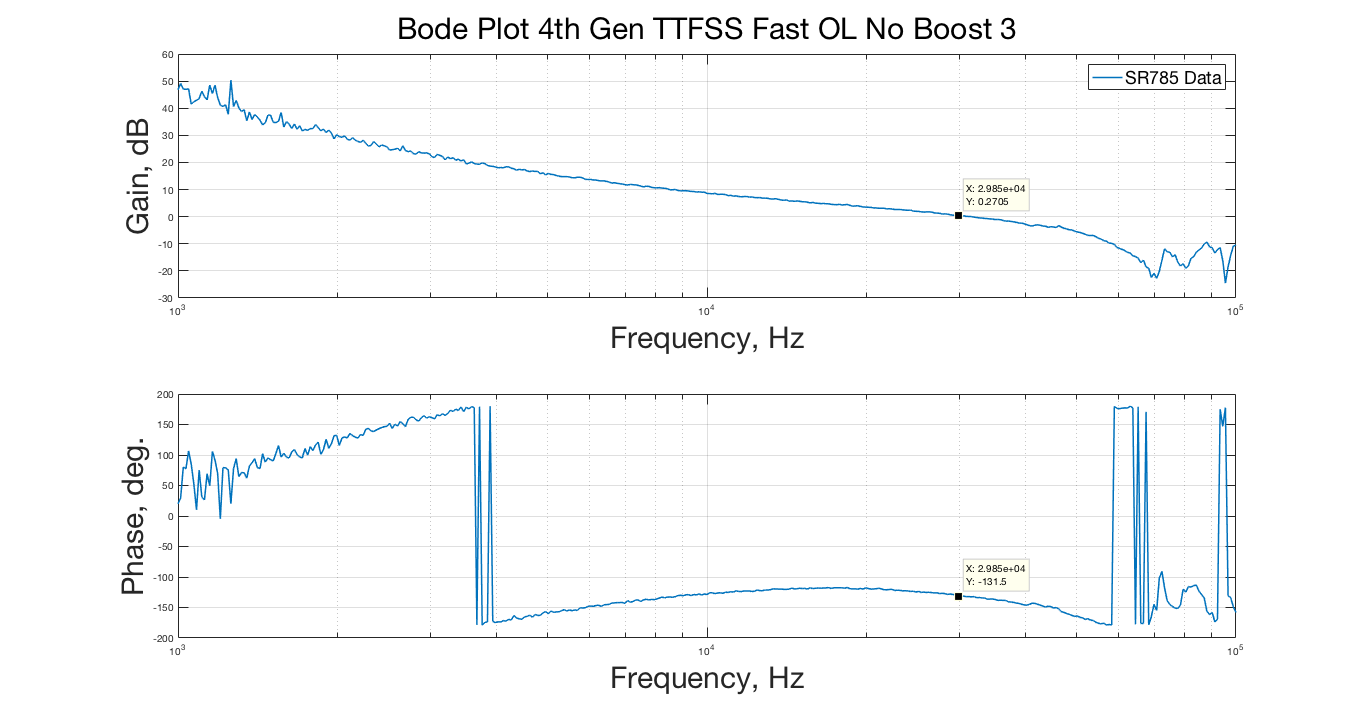

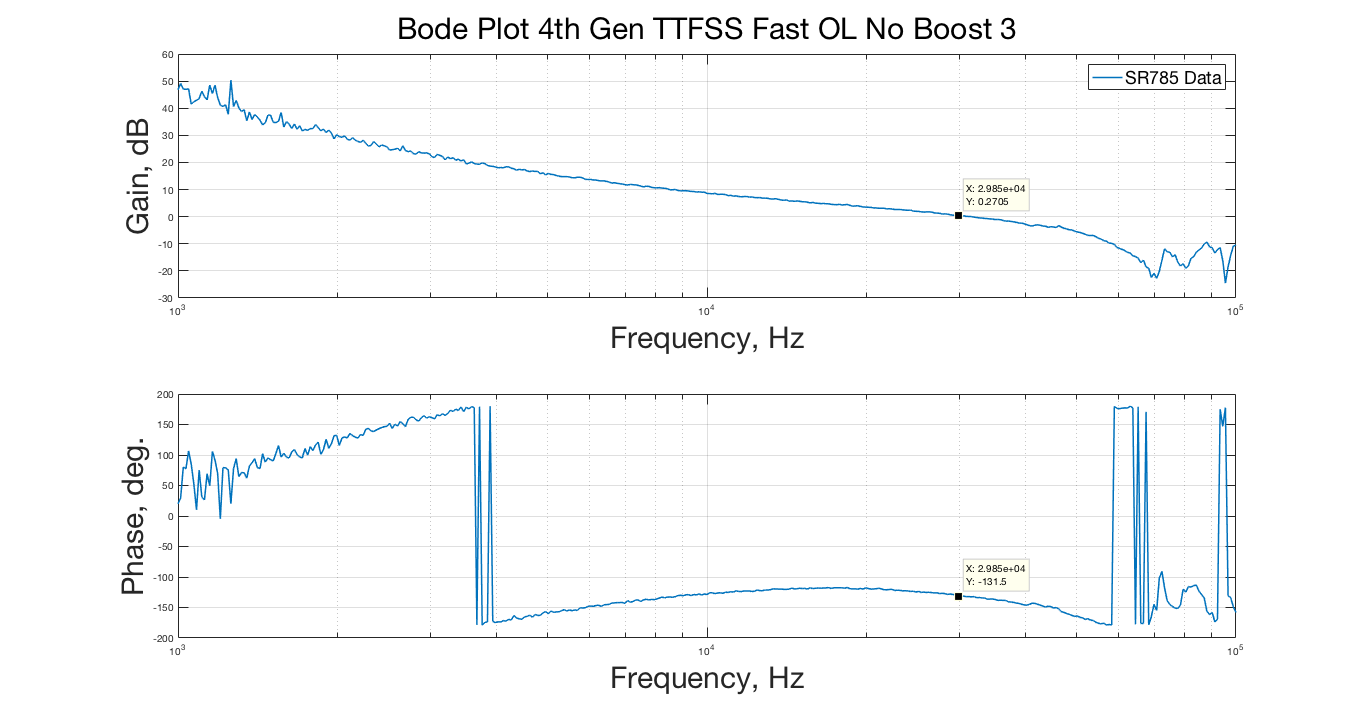

Here attached a fast path open-loop gain transfer function of a 4th gen TTFSS. The crossover between PZT and EOM is at ~30kHz, Common gain was 17dB, Fast gain was 22dB, and Boost 3 was not engaged.

Daniel, Nutsinee

Here attached a fast path open-loop gain transfer function of a 4th gen TTFSS. The crossover between PZT and EOM is at ~30kHz, Common gain was 17dB, Fast gain was 22dB, and Boost 3 was not engaged.

Updated the dust monitor AlarmHandler to reflect the post vent CS and ES vent configuration. Dust monitors currently being monitored by the AlarmHandler are:

CS LVEA 5 = HAM5, CS LVEA 6 = HAM6, CS LVEA 10 = Biergarten, EX VEA 1 = EX VEA, EX VEA 2 = BSC Cleanroom, EY VEA 1 = EY VEA, EY 2 = BSC Cleanroom

There were no changes to the other dust monitors configurations, locations, or alarm levels.

Kyle, Chandra

IP4 arrived from vendor after being fully rebuilt, baked, and shipped under vacuum. We connected it to a aux cart to pump out from found ~e-4 Torr to e-6 Torr and then applied 7 kV to both channels. Then vented with dry N2, pumped out and applied 7 kV to find that the current is a factor of ten higher than first test. This may be normal because of the exposure to gas, but LLO doesn't show the same results, and it reads higher than the other pumps in operation.

Sheila, Nutsinee, Terry,

This is an update on the progress so far on the VIP. We have aligned and mode matched both the CLF/seed 1064 path and the 532 pump path to the OPO, and are ready to think about swapping M1 for the higher green reflectivity version.

Here's the green data (+PZT calibration). Note that the data hasn't been corrected for dark current.

I corrected the green data for dark current as Sheila suggested. The mode matching calculated from transmitted power is now 73.5%. The dips in reflected power are 78.8% of the power off resonance. Higher order modes has not been taken into account.

With Bubba and Mark's help, Betsy and I reinstalled the newly welded and AERM'd ETMy quad lower structure into BSC10 and mated it to the upper structure. The whole process went very smoothly and took ~2 hours total.

Sheila, TVo

I had trouble locking the IMC yesterday when increasing the input power. So we measured the OL TF at the Common Mode board and found that the UGF was about 100 kHz with maybe 20 degrees phase margin while locked at 1 W. So we changed the guardian common mode gain calc by -4db to get a little more phase margin and match what Kiwmau's suggestion was in aLOG-36354 of about 50 kHz nominal, it now stably working at 10W. I've attached the plots of different power levels input into the IMC.

![]()

15:45 - 17:41 UTC Jeff B. to end X for work on dust monitors 16:10 - 16:19 UTC Peter to optics lab to get lens tissue 16:43 - 17:30 UTC Filiberto to end X to help Jeff B. with dust monitors 17:00 UTC Terry to squeezer bay (most of morning) 17:07 - 17:15 UTC Travis to LVEA to retrieve parts for HAM6 work 18:06 UTC Pepsi delivering vending machine 18:07 UTC Filiberto to LVEA to inspect illuminator cabling 18:09 - 18:36 UTC Sheila, Thomas to LVEA to measure IMC open loop gain 18:12 - 18:25 UTC Nutsinee to squeezer bay 18:17 UTC Kyle to mid Y 18:21 UTC Travis, Betsy, Bubba, Mark to end Y to put quad back in chamber 18:55 UTC Karen to mid Y 19:00 UTC Handoff OPS to Jim

Dave B., Filiberto C., Jeff B. The in cleanroom dust monitor(VEA 2) has been installed at End-X to support the up coming vent. Dave did the updates to dust monitor software to remove the unused monitors from the LVEA and add monitors for the end stations. The End-X monitors were (1) incorrectly connected to the RS485 serial network, and (2) A wire loop in an unused but connected RS232 box was shorted. Filiberto and I reconnected the dust monitors correctly for the RS485 serial network. While trouble shooting network intermittent lockups, we found and isolated the shorted RS232 wiring. Both end stations dust monitors are up and running. The AlarmHandler and "check_dust_monitors-are-working" scripts are being edited to reflect the current operating environment.

This morning the pre-modecleaner reflected spot looked like it had moved compared to yesterday. This led to the suspicion that the output of the laser had dropped - it had. I increased the diode currents by 1A to bring the power back up. Did a quick diode temperature check but things are pretty good where they are right now.

Keita TVo

We first set the final position of the fast shutter and the cable routing as well as position the reflection of the shutter to the center of the beam dump. This is done and the fast shutter has one tightened dog clamp on each side. The incoming beam from HAM5 clears the shutter wire by 10 mm and the structure is even further than that. We had similar difficulties with closing and opening the shutter as yesterday but Keita seems to have found a way to make it work with some odd logic that he will post about in a comment.

We've also aligned the AS_AIR path through to the viewport simulator as well as the beam diverter and the beam dump. Note of caution, when Jason and I installed the viewport emulator, it was already well aligned to three blank flanges on the other door of HAM6. Keita reminded me that this is not the same as an actual viewport with its viewport protector housing attached so we tried our best guess to account for this by eye when aligning the beam coming out of the chamber. I've attached a picture that shoes where the beam is coming out of the emulator, it is at the bottom most corner of the laser card.

Next step was OMC_TRANS path which was particularly difficult because the OMC would not stably lock with the purge air on and even when it was locked, we were not able to see anything coming out of the shroud. It was getting a bit late by this point and this alignment should be done with three people

Fast shutter:

Temporary HV PSU was disconnected and the cable from the power rack was plugged into the FS driver. Front panel "HV enable" switch was turned on. After this the "open" "close" buttons on the FS MEDM screen worked, "close" would close the shutter as long as you'd like.

Odd thing was this:

Shutter was initially open -> Set the threshold negative (instead of using FS MEDM open/close button) -> Shutter would close immediately -> But the shutter would go back open after two to three seconds.

You would think that whenever the trigger diode shows a larger power than the threshold the shutter is always open. But maybe this is OK as the FS is the protection for lock loss, we don't expect continuous huge power.

Odder thing was this:

Shutter was open -> Set the threshold negative -> Shutter would close immediately -> Didn't wait for two or three sec, quickly set the threshold back to some positive number or zero -> Shutter would stay open.

I don't understand the logic here.

Pictures

1st: centering on FS when it's closed.

2nd: beam-FS wire distance more than 10mm.

3rd: high power beam dump when FS is closed.

Chandra, Gerardo, Kyle We would like the option of removing GV12's external gate annulus piping so as to relieve a potential interference with the to-be-installed bake enclosure that will encompass GV12, CP4 and GV11. This enclosure will allow the bake-out of CP4 as part of its decommissioning. Removing this external piping requires venting the annulus volume for a long enough duration as to remove the piping, blank-off one of two ports and then install a valve on the unblanked port which would allow the re-evacuation of the vented volume. Unfortunately, as was the case with GV11, GV12's gate annulus O-rings leak into the adjacent vacuum volumes (Y2 beam tube module and CP4) and thus limit how much time we could tolerate the annulus volume being vented. We recently demonstrated this by admitting UHP N2 into GV12's gate annulus and then observing the pressure response in the adjacent vacuum volumes. Today, in an effort to reduce or eliminate GV12's poor sealing gate, we "slow" opened it by letting the variable speed electric actuation motor ramp up from 0 rpm up to 1000 rpm and then pausing for 30 seconds to allow the "sticky" O-rings to pull away from sealing surface. This gets repeated a few times until the adjacent volume's pressure gauges confirm that the gate is no longer in contact with the sealing surface. Once the gate is freed, we then "hard closed" GV12. Next, we administered ~ 1 LPM of UHP N2 into the entirety (combined) annulus volume for 3 minutes before aborting the gas admission and evacuating.

Kyle, Gerardo We need this at Y-mid for Class-A work at CP4

Analog cameras installed, aligned, and hooked up to power and BNC cables. Camera BNC cables are named PRM, MC1, and MC3. PRM is viewable from the CR. MC1 and MC3 show video lost. Not sure if cables at HAM2 match the analog camera medm. And... after I finished writing this, I went to change the top monitor in the CR to PRM, and I don't seem to be able to change that monitor now.

- Hugh, Cheryl

16:45 Travis to optics lab

16:50 Hugh to LVEA for survey equipment

17:10 Peter to optics lab, out 17:30

17:50 Hugh to BS, looking at HEPI actuators

18:00 JeffB to HAM6 for dust monitor

18:00 Nutsinee Daniel to SQZ

18:10 Tvo, Jason putting viewport emulator on HAM6

18:40 Jason, Kyle Gerardo looking at oring protectors for HAM6

19:00 Elizabeth to HAM6 racks

19:20 JeffB to EX

19:30 Chandra, JohnW to LVEA

20:00 Terry to SQZ

20:30 Betsy Travis to EY, back 23:20

21:00 Elizabeth to MY

21:00 Kyle Gerardo opening LVEA rollup door

21:00 Cheryl working on analog camera at HAM2

21:15 Keita Tvo to HAM6

21:40 Kyle Gerardo to MY

21:40 JeffB to both ends

22:35 Kyle Gerardo Chandra working on GV12, done 24:00

23:05 JeffB to EX

This afternoon, Travis and I rolled the ETMY/PUM monolithic main chain from the weld room around to it's AERM/PenRe reaction chain pal in the staging room next to the chamber. We used the Genie duct jack to lift the ETMY set from it's trolley and place it next to the AERM double. After some alignment checks, we pushed them together and fastened up their 8 mating screws. We left the newly married couple covered and ready for tomorrow's big adventure back into the chamber to meet their upper half.

Thanks Peter for the photo assay of today's work on this!

Nutsinee Marc Daniel

The (hopefully) final version of the TTFSS V4 has been installed. The modifications are described in E1700364. To increase the beat note strength the first directional coupler in the TTFSS preamplifier has been replaced by a splitter which results in 8dB more gain.

The ugf is around 500kHz with a crossover around 30kHz. The autolocker seems to be working fine too. Plots to follow.

Filiberto, Hugh, Patrick, Richard This morning Hugh and I took the end X ISI guardian to ISI_DAMPED_HEPI_OFFLINE. Hugh and Filiberto then went to end X and Filiberto moved the wiring from the existing HEPI pump controller box over to the Beckhoff box. We found some minor issues with the Beckhoff PLC code that I corrected. Restarting the PLC code tripped off the power to the HEPI pump motor and I went to end X to reset it. We have since tuned the Beckhoff PID (actually just PI) and will leave it running overnight.

Filiberto, Richard, Patrick Today we took it off of PID control and ramped down the VFD. Filiberto then went to end X and connected the VFD readback signals to the Beckhoff terminal. We then turned the PID back on. It is currently keeping the differential pressure at 70 psi.