Daniel, Sheila, Terry, Nutsinee

We locked the thing!

Below are some of the relevant information:

Broad Band PD at SHG transmitted (Design document: https://dcc.ligo.org/LIGO-T1100467)

Responsivity (1064) = 0.1A/W

Transimpedance = 2kOhms

Calculated power hitting the PD = 10mW

EOM1 (Newport 4004 Broad Band Phase Modulator)

Modulation response = 15 mrad/V @1000nm

Drive voltage = 1.5Vp (1Vrms)

Modulation Depth = 22.5 mrad

Other values:

Measured transmitted DC level = 2V

Measured RF power envelope (peak-peak) = 8mV

Measured PDH error signal (peak-peak) = 40mV

FSR of the SHG cavity = 3GHz (cavity length ~2.5cm, KTP crystal index of refraction = 1.80302 gives 2.75 cm extra path length. This 3GHz number was also found buried in SURF report by Nathan Zhao)

Finesse = 89.75 (used r=0.9, value for the input coupler) I mistyped the % earlier. Finesse is just a number, not percentage.

Calculated Linewidth = 30MHz

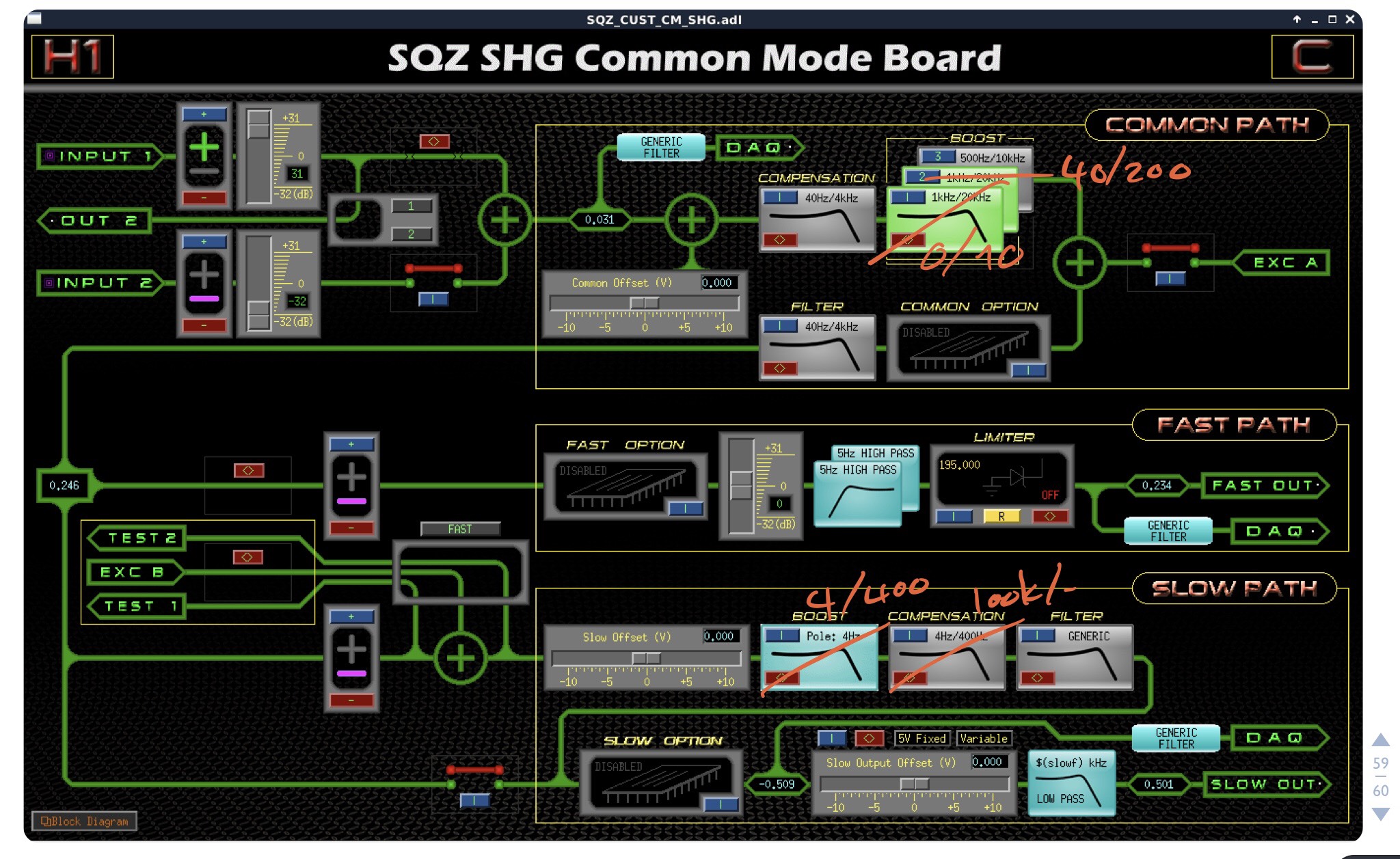

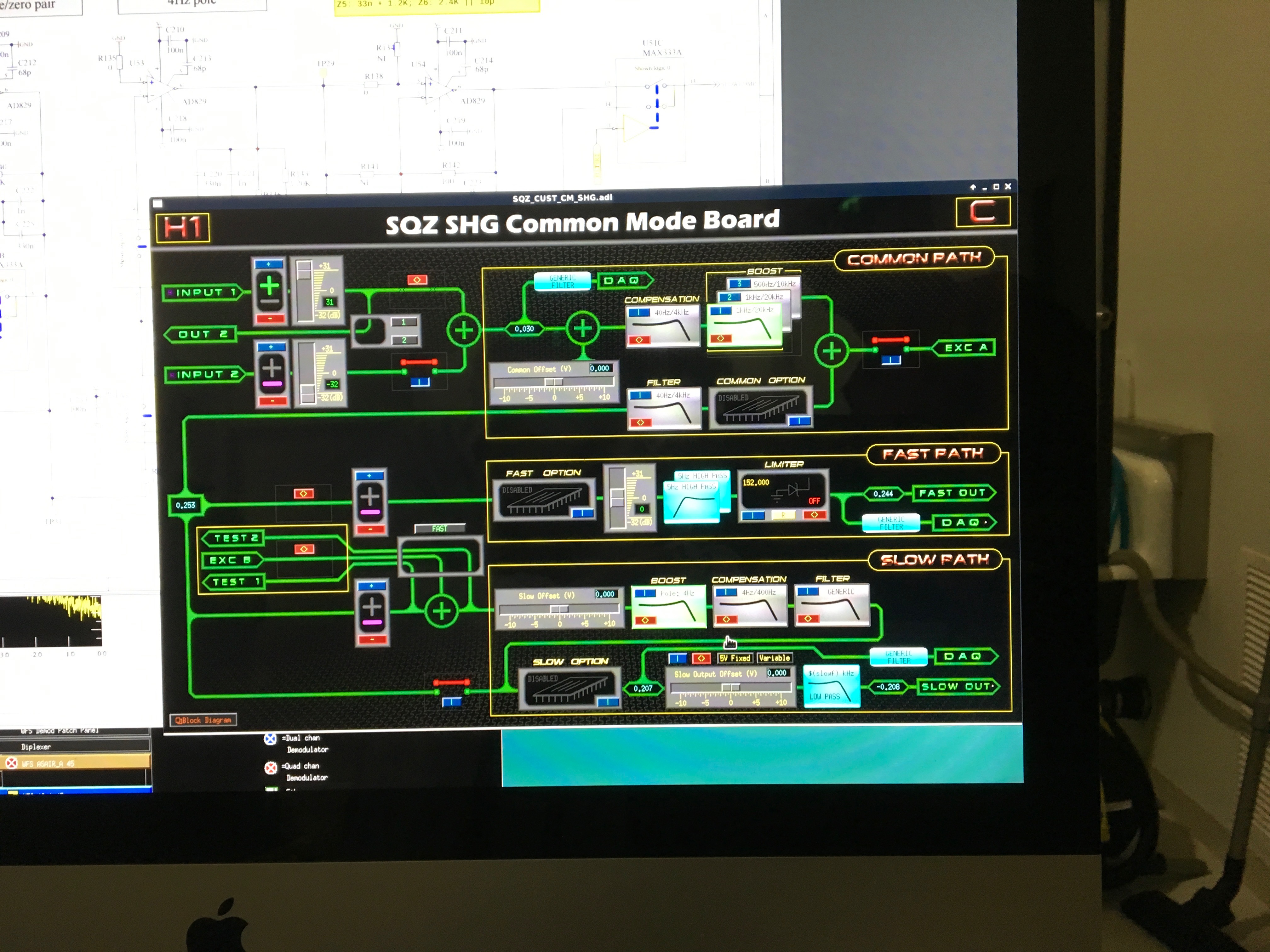

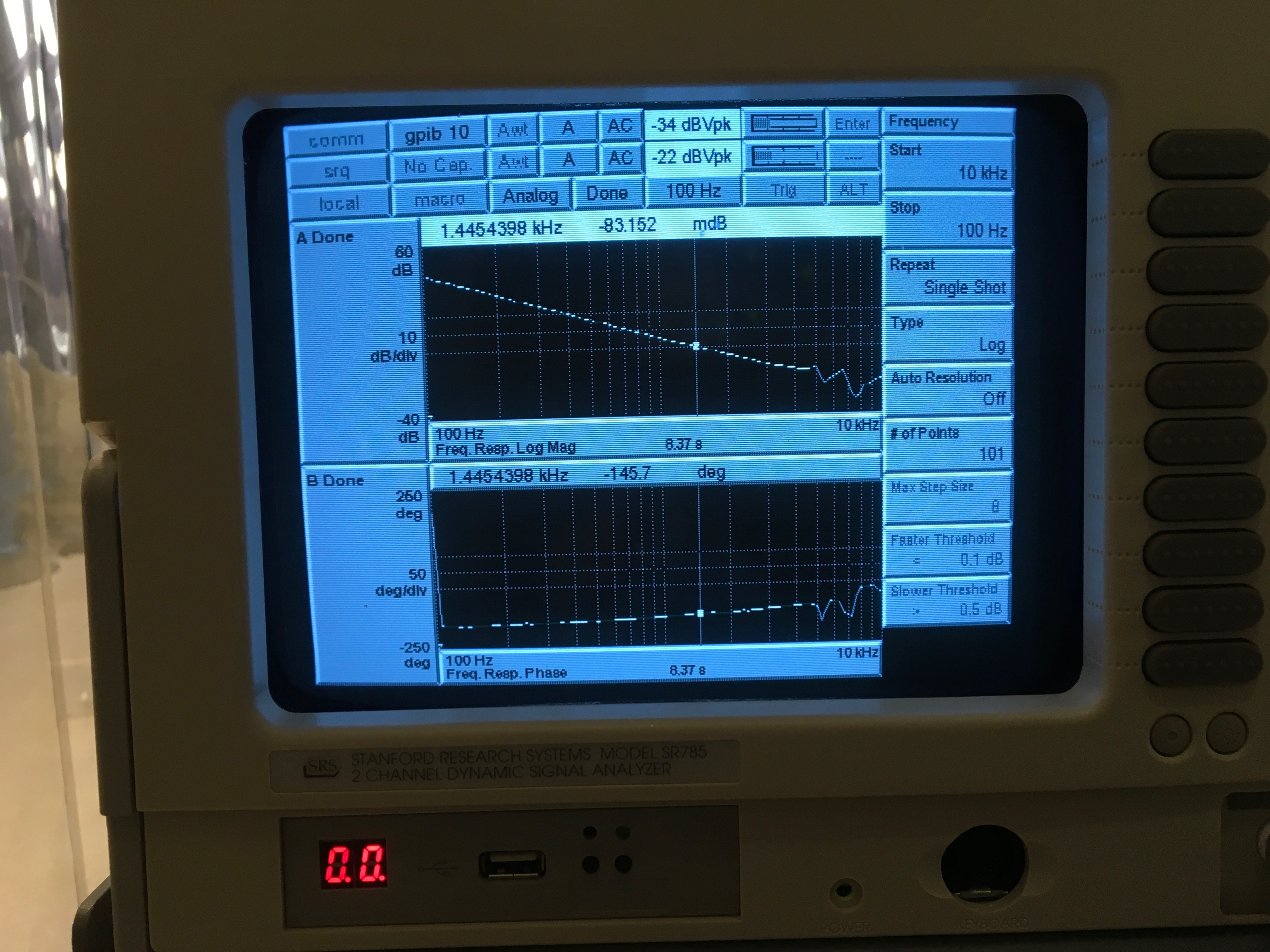

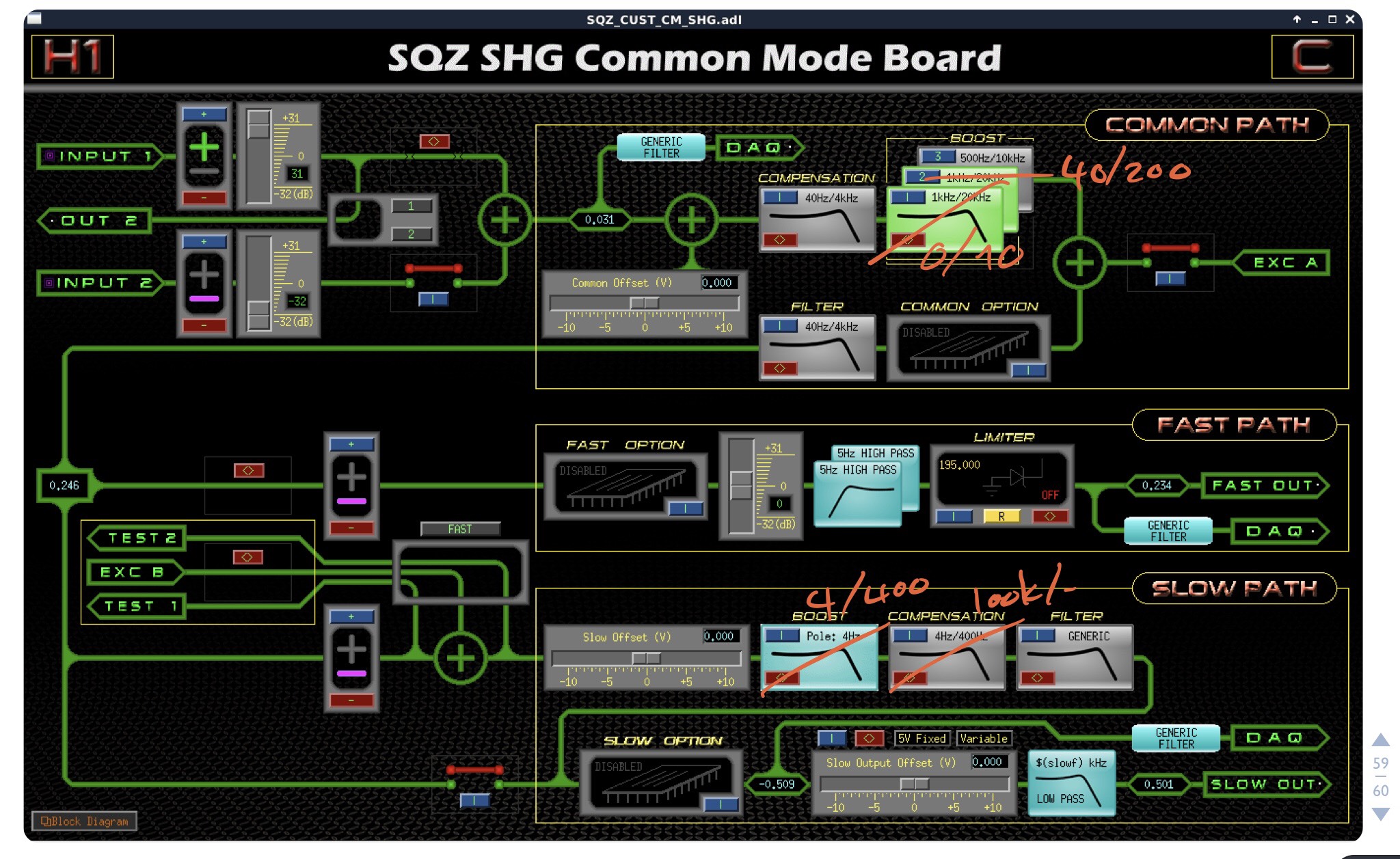

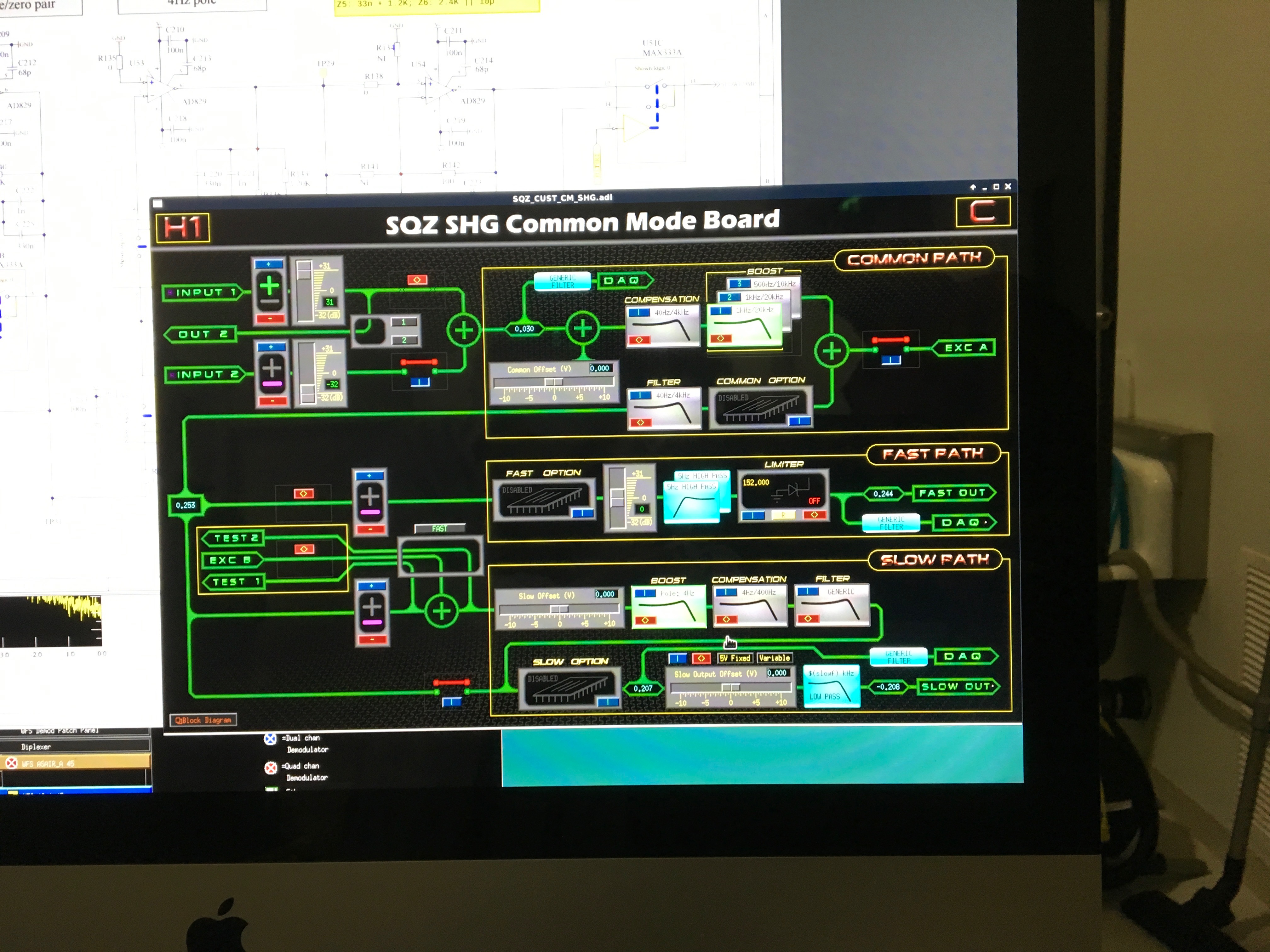

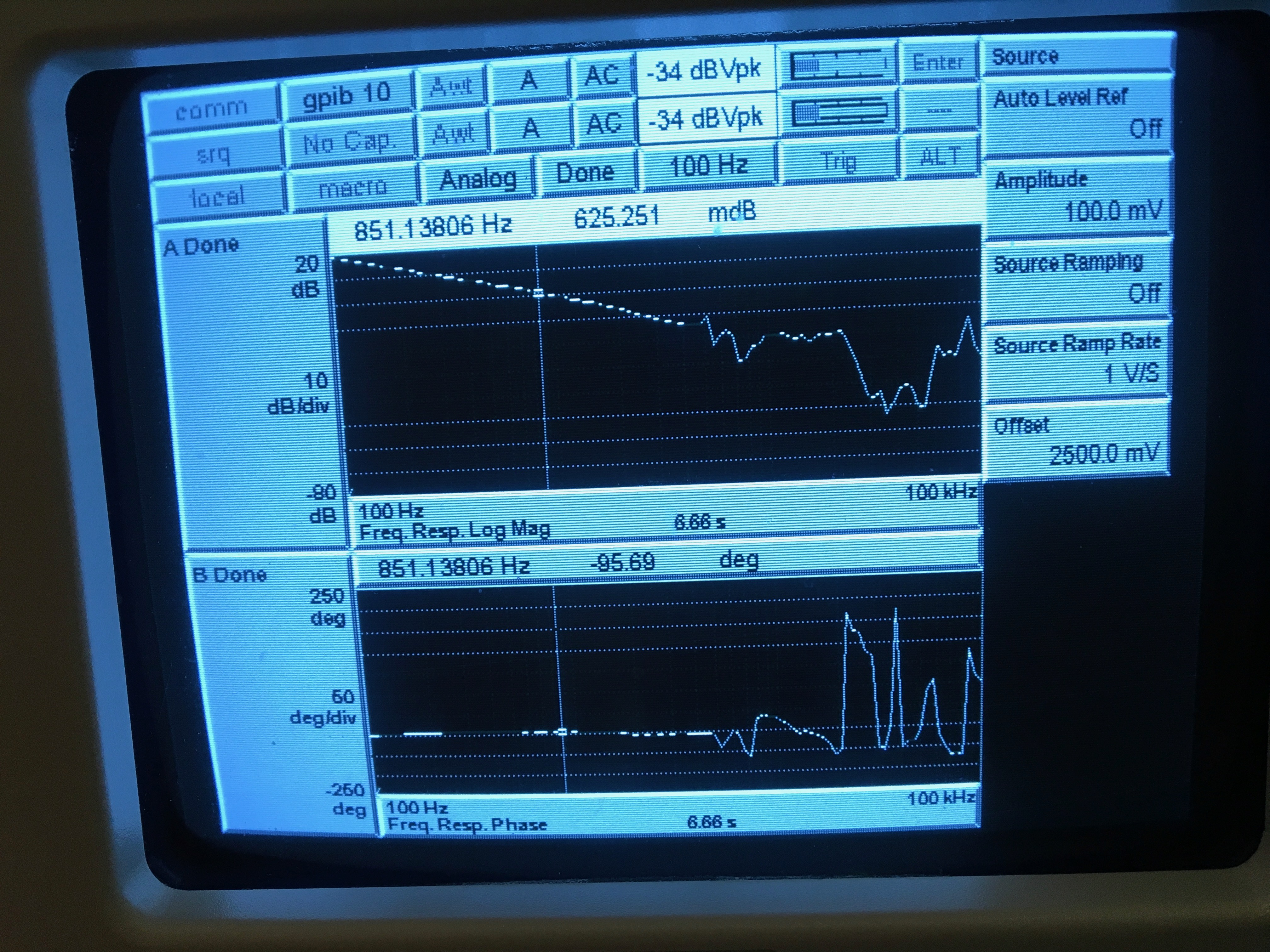

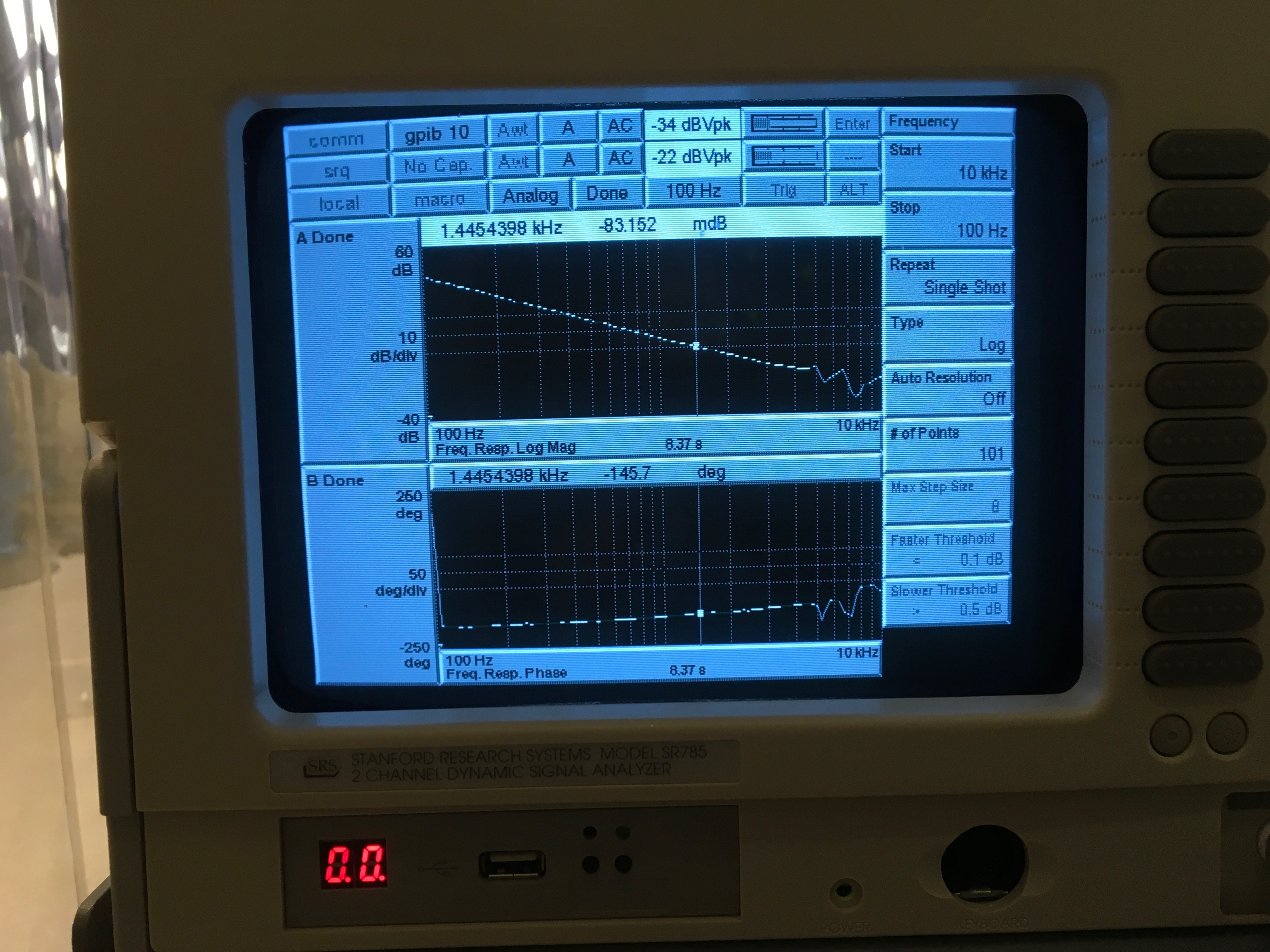

Open-loop gain transfer function

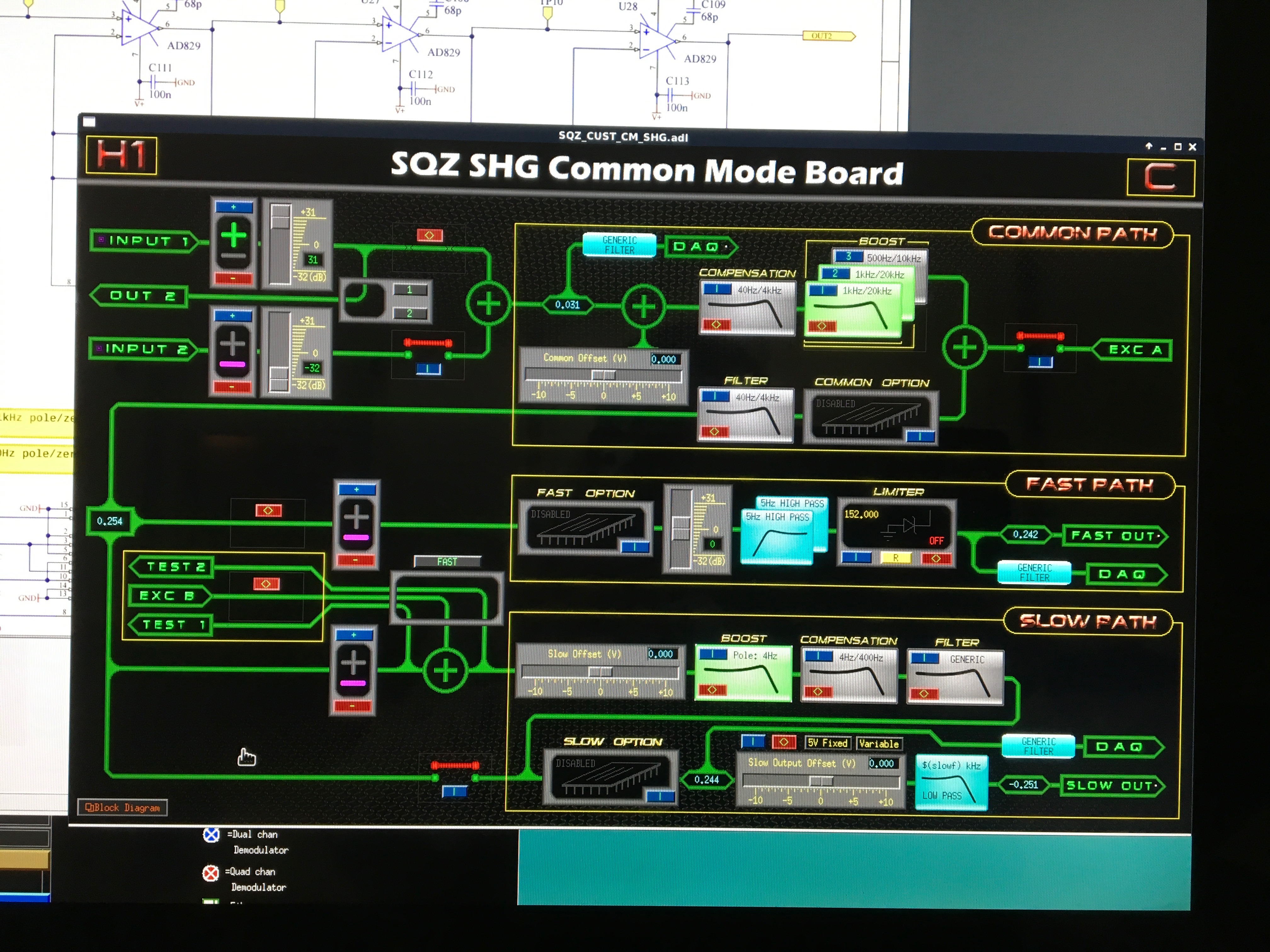

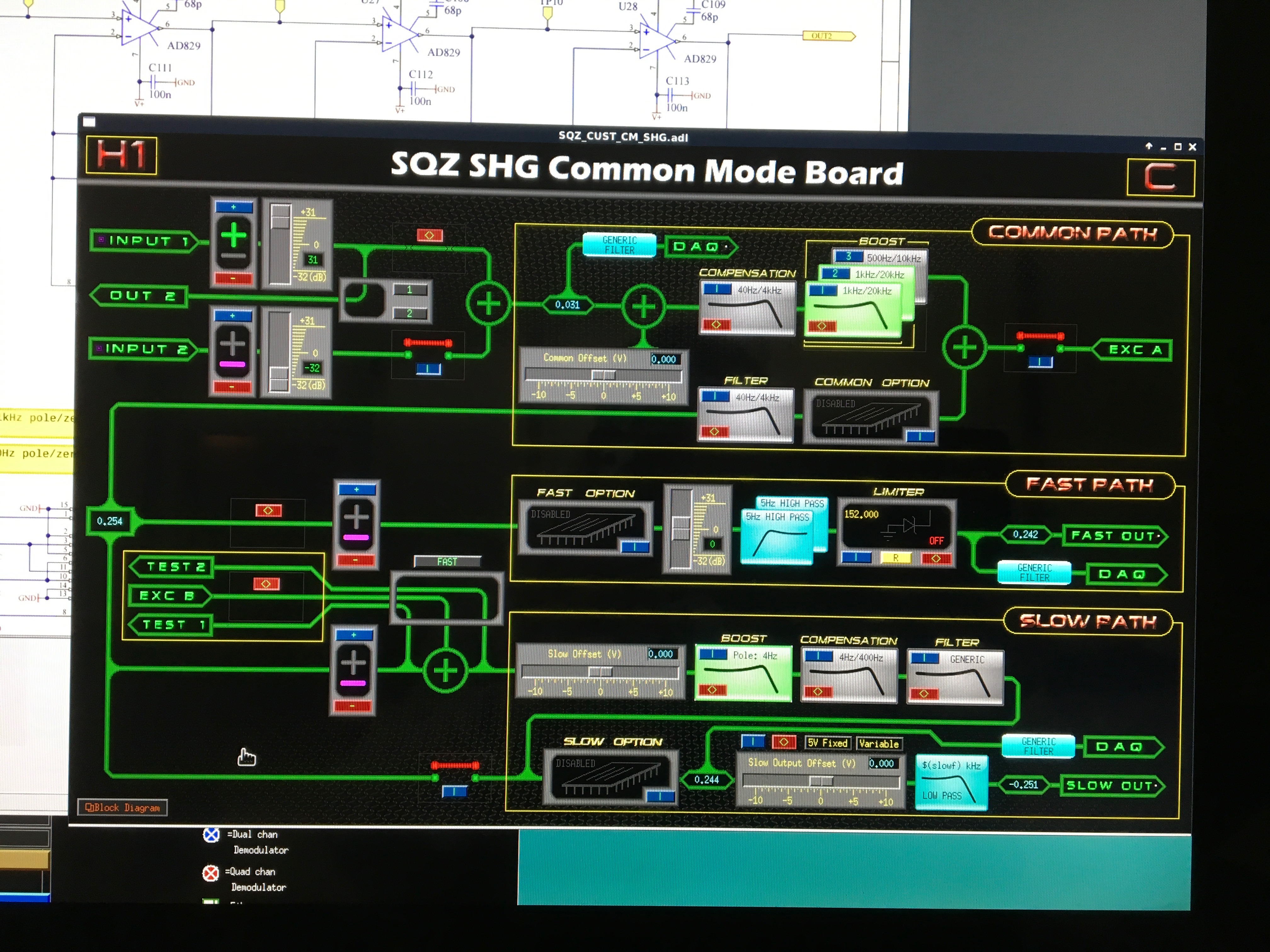

The boost labels on the medm screen are still wrong. That's due to be fixed.

The first boost in the common path is actually 0/10 (pole/zero) and the second boost is 40/200

The "boost" in the slow path is actually "compensation" (4/400) and the "compensation" is just a pole at 100kHz with no zero.

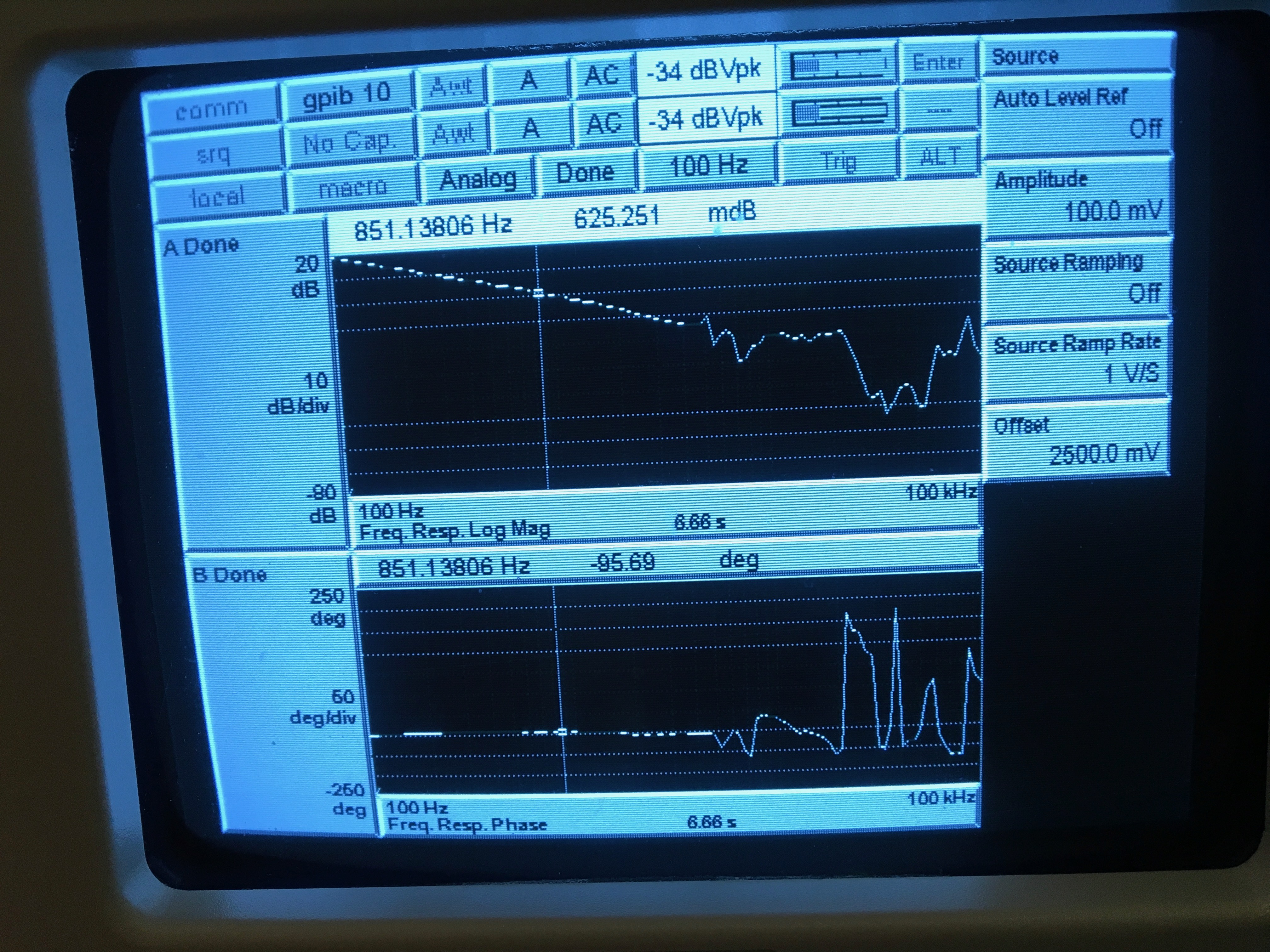

TF WITHOUT common path second boost engaged has UGF at ~850Hz

TF WITH common path second boost engaged has UGF at ~1.5kHz

Other stuff worth mentioning

- SHG TEC control is now working

- SHG and CLF common mode board retested after the wrong wiring was fixed-- they're good