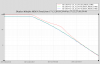

This afternoon Kyle and I valved in OMC turbo and YMB turbo. The XBM turbo is spun up but valved out and backed by its scroll. Kyle will lower pressure set points before he leaves today. Corner pressure is 10 mTorr.

HAM 1 turbo was valved in for a second but the power cord needs to be secured better so it was spun back down; will resume tomorrow. PT-100B CC gauge tripped and has been reset. Chamber pressure is 0.1 mTorr.

Aux turbo cart was moved from BSC 3 annulus to BSC 2 annulus.

Tyler and Mark are working on building three more TMDS tables.

Terry was on site today working in sqeezer bay.

Adjusted YBM and Vertex MTP safety valve threshold/setponts to their nominal values of 5.0 x 10-2 torr (foreline pressure at which MTPs isolate from VE). Also, I closed the IMC, OMC, YBM and XBM vent/purge valves now that we are on the Turbos and the "dead" volumes between the valve seals and the hose connection blank-offs have been pumped to a rough vacuum. Terry had coordinated with us today as to his arrival, work area and eventual departure. 1755 hrs. local -> Kyle leaving site now (unaware of anyone else on site at this time)