1) Resonances of the ITMX elliptical baffle match peaks in DARM. Several peaks in DARM, (e.g 70 and 106 Hz), were thought to be due to the elliptical baffles, either or both ITMX and ITMY baffles. This is because, for different vibration injections, the amplitude of these peaks in DARM were best explained by the vibration level at ST0 of BSC2, and these baffles hang from this stage of the ISI ( https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=26016, https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=31886 ). To make sure that this identification was correct, I measured the elliptical baffle resonances with an in-chamber accelerometer while tapping on them. Figure 1 shows that resonances of the ITMX elliptical baffle match the DARM peaks, but the ITMY baffle resonances do not. Betsy will check to see if the ITMX baffle down-tube is misaligned when the upgraded baffle is installed.

2) Possible sources of scattering in BS chamber. Follow-up PEM injections showed that shaking the walls of BSC2 produced noise in DARM (https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=39121 ).

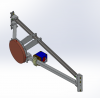

One long term concern in BSC2 is the TCS mirror 2 and its support structure that is attached to the BSC2 wall: https://alog.ligo-wa.caltech.edu/aLOG/uploads/9564_20140126161227_Figure2-ITMXcompensationPlate.pdf .

Scattering associated with the mirror could either be from the support region surrounding the mirror or from the nozzle and flange holding the TCS ports, visible in the mirror (see Figure 2 and https://alog.ligo-wa.caltech.edu/aLOG/uploads/9564_20140126161227_Figure2-ITMXcompensationPlate.pdf ). The region around the mirror could be baffled and the port could be baffled. I talked to Steven about the possibility of a port baffle that might also be useful at the P-Cal transmitter and receiver ports.

Another mitigation possibility is to damp the motion of the mirror. I tried a very simple method illustrated in Figure 3 that seems to have reduced the Q’s of some of the resonances by 2 or 3. I think we could do a lot better by wrapping the struts with more material.

A second possible source of the scattering noise are the BS chamber walls themselves, which are nearly normal to wide angle scattering from the beam spot as illustrated in Figure 3.

A final possibility is the elliptical baffle: I wasn’t able to eliminate this possibility because in the 14-17.5 Hz band we haven’t made strong enough injections with HEPI to exclude ST0 (discussed here: https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=39121).

3) Scattering at P-Cal ports. Nothing new to report beyond https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=39121, except that I discussed port baffle design with Stephen Appert.

4) HAM1-HAM2 septum not shielded from spot on beam splitter

Figure 4 shows that the HAM1-2 septum is visible from the BS through the structures on HAM2. The septum is a concern because of its high reflectivity and the fact that it is not seismically isolated like the reflectors on HAM2. The baffles are not yet all installed on HAM2, but I think the baffles will leave the upper regions of the HAM1-2 septum exposed to the BS. There is not an equivalent exposure of the HAM5-6 septum because the central part of the MC baffle in front of HAM5 remains in place, while the central part of the MC baffle in front of HAM2 has been removed.

5) “Temporary” floors should probably be removed for scattering reasons. The floors placed inside the chambers for working are sometimes left in place. Figure 5 shows that they may create scattering paths and should probably not be stored in place. I think Betsy was already planning to do this for charge imaging and other reasons.