looks like h1ecaty1 needs a restart.

looks like h1ecaty1 needs a restart.

Installation of the Hardware Watchdog System (HWWD) update.

Yesterday the ITMY/ITMX ISI coil drivers were replaced.

S1103345, S1103335, and S1103350 in SEI-C4.

S1103357, S1103341, and S1103334 in SEI-C6.

New units have the following modifications complete:

1. HWWD keep alive BNC back panel modification and new power board

2. E1300535: DCN for SEI Coil Driver regulator transient protection

3. E1100821: Change notice to bring ISI Coil Drivers to a rev. v2

4. Check front panel reset switch is correctly wired.

New units installed:

S1103340, S1103364, and S1103339 in SEI-C4

S1103358, S1202291, and S1103307 in SEI-C6.

New coil drivers require a ~15V signal on the BNC connector located on the back panel. Signal comes from the D1300642 HWWD chassis located in SUS-C6.

All HAM and BSC2 coil drivers will be checked/modified to ensure modifications listed above are complete with the exception of the back panel BNC modification.

I don't know if we're getting better and better to find defects in the mirrors, maybe the flashlights we use are getting brighter, but anyway our iLIGO 2" optics all have some contamination or defects (I think they're defects), some much worse than the others.

We have total of 7 such iLIGO optics at hand, we inspected them all, and chose one as relatively good, another one as OK. These are to be installed for SQZ path.

Attached are the cellphone pictures of these optics. View them in full resolution to observe the defects/contaminations that are marked by yellow closed curves. I haven't noticed all of these until I took pictures. But Optic 1, 2, 6 and 7 were clearly worse than 3, 4 and 5 by just visual inspection.

Green closed curve on Optic 2 show what I think is NOT on the HR.

Optic 1: Lots of what seem to be scratches and oval dimples to me. I tried and failed to move/wipe using dry Q tip. If you're VERY careful in your lighting the oval dimples looks oval to naked eyes.

Optic 2: Lots of what seem like deep scratches.

Optic 3: Defects are smaller and fewer. This is the best one.

Optic 4: Not the best. This is the second choice.

Optic 5: Many things at around the center though they are smaller than the worst ones. Somewhat worse than Optic 4 to me. Three deep dimples at the edge at 120 degrees angle.

Optic 6: Big things at the center.

Optic 7: Marginally better than optic 6.

Removed the damaged glass from OMC REFL Beam Diverter Dump (3-large pieces removed & smaller shards/dust removed on best effort). New glass was installed.

Added this alog entry to FRS ticket Ticket 9196 - WHAM6 OMC REFL Beam Diverter Dump Glass Broken

(Corey, Keita, TJ)

Yesterday (Mon), I gathered (4) HR mirrors for installation into Squeezer Tip Tilts (These are E040516iLIGO E040516's). I basically applied First Contact (on both sides of all optics) & left them over night. Unfortunately, this morning after TJ & I removed the First Contact, the HR surfaces didn't look very clean. Keita came to put a second pair of eyes on them, and also felt they were not acceptable. So, he applied First Contact to them + the remaining other (3) spares for a total of (7). Documents say they should cure for atleast 4hrs before removing FC, but Betsy said they are generally good after an hour. So in the afternoon, we removed the FC and inspected. Out of the (7) Keita worked on, (2) of them were OK/acceptable. So we are going to go ahead and use these for the HAM5 &6 Tip Tilts.

(The other E040516's were photographed by Keita. We probably no longer have any usable spares....other than 3IFO.)

Keita took the (2) acceptable mirrors, cleaned their not-grounded (i.e. clear) barrels with Acetone and then reapplied First Contact on the optics for their installation/transport.

The plan is to install one or both of these in the Tip Tilts tomorrow (Wed).

Corey and I damped output arm MC baffles. The figure shows the locations of all dampers. We mainly followed details in: https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=38757 but placed an extra (fourth) cork at the top of each baffle, and damped one panel gap on the outside, where most of the gaps are not as wide because the bolt spacing is closer.

Got the south side C2 BB Blade damper, flexure damper, and the C3 vertical GS13 can damper installed. Can't avoid it, now I have to go in chamber to do the rest. We'll do that tomorrow and get the B&K done.

TITLE: 10/24 Day Shift: 15:00-23:00 UTC (08:00-16:00 PST), all times posted in UTC STATE of H1: Planned Engineering LOG: 14:15 UTC Peter to optics lab 15:12 UTC Fire department here to hang 'out of service' tags on all the RFARS 15:30 UTC Bubba and Chris lubricating fans 15:30 UTC Peter back 15:39 UTC Christina to end X to clean 15:50 UTC Cintas through gate 15:52 UTC Karen and Vanessa to end Y 16:07 UTC Filiberto WP 7188, only in CER today 16:07 UTC TJ to LVEA to locate parts 16:31 UTC Hugh to LVEA 16:51 UTC TJ back 16:53 UTC Ed to help Filiberto in CER 16:56 UTC Karen and Vanessa leaving end Y 17:07 UTC Corey to LVEA entrance bay for a few minutes to get contamination control equipment 17:36 UTC Richard to CER to find Filiberto 17:37 UTC Bubba and Chris done lubricating fans in outbuildings. Need to wait for CS. 17:37 UTC DAQ restart 17:44 UTC DAQ restarted, keeping nds0 down to look at its memory 18:14 UTC Corey to LVEA for 15 minutes to look for first contact and green lantern flashlight 18:23 - 18:27 UTC Amber leading school tour in CR 18:23 UTC Paradise water delivery 18:51 UTC Peter to optics lab 19:51 UTC Richard to LVEA, testing PT120A calibration 20:09 UTC Betsy to work on SR2 in HAM4 20:16 UTC Dave taking down h1nds1 20:34 UTC Dave done with nds1, going to CER 20:37 UTC Richard done 20:58 UTC Hugh to HAM4 to install ISI damping 21:47 UTC Corey to HAM4 to install OMC baffle damping 21:54 UTC Betsy done 21:58 UTC Robert to HAM4 to work with Corey 21:58 UTC h1nds1 restart 22:13 UTC Kingsoft water to do service on RO 22:53 UTC Peter done in optics lab

FRS 8198

Today I upgraded the memory capacity on h1nds1 from 48GB to 72GB. This means both nds servers now have the same memory size. Earlier this morning I looked inside h1nds0 to verify its memory card configuration (three 8GB and three 16GB cards).

In conjunction with expanding the memory, h1nds1's daqdrc configuration file was modified to use the additional capacity by changing the buffer size in the 'start main' command from 50 to 100.

h1nds1 has two banks of three DIMM slots (three black, three blue, interleaved). Initially all six slots had 8GB cards. The three black-slot cards were replaced with three 16GB cards.

h1nds1 was restarted twice, once after the memory upgrade, the second with the new daqdrc configuration.

Hugh hit a stopping point on the last ISI damper install since he needed access to the bolts under the SR2 suspension. Since we are planning to translate that suspension per a new ECR anyway, I marked it's pointing on 2 faces of it's base with dog clamps and then slid it out of the way for Hugh. He is continuing his work now.

Also had to do a similar mark-with-dogs and move the newly aligned 4" Siskiyou mirror that was also sitting on holes that Hugh needed to access...

The YBM turbo pump was vented with room air to facilitate the replacement of the bellows and 10" gate valve at its inlet (WP7180). Following leak testing of these new joints, the turbo was left running while backed by its local scroll pump (10" valve closed, WP #7186). The turbo inlet pressure achieved 1.0 x 10-8 torr (foreline 2.3 x 10-3 torr) after 15 hours. As such, baking won't be necessary. I shut down the clean room, turbo and scroll pumps. This completes WP #7180 and WP #7186

Ed, Richard, Fil, Dave:

we tested the ITMY HWWD by disconnecting one of the DB-37 front connectors which simulates a failed OSEM-LED. I modified my MEDM screen to show the countdown of the Time To Fail (TTF). I also added a red border if the TTF minute value falls below 19 minutes. Attached screens show the countdown at the 4 minute mark, and after the SEI (ISI) coil drivers had been powered down. In this test this happed at 0:20 in the count down.

I further tested that the unit could not be reset (via the front panel button) if the fault condition was ongoing. After plugging in the satellite amp cable and removing the fault condition, I was successful in resetting ITMYs HWWD and BSC1 ISI coil driver chassis sprung to life.

Everything looks nominally ok.

at 10:37 PDT I restarted the DAQ in order to:

rsync with h1omc's ini file (following units typo correction)

temporarily remove H1EDCU_CONLOG from DAQ (while conlog is down)

use the latest Squeezer Beckhoff EDCU ini file (H1EDCU_ECATC1PLC4.ini)

The EDCU is now GREEN again, we should investigate if it turns RED.

While doing my usual Tuesday morning rounds of the PSL system, I noticed the crystal chiller was starting to get low on water. I added 150 mL of water; while this didn't quite top the chiller off, it got pretty close.

This morning I completed the weekly PSL FAMIS tasks.

HPO Pump Diode Current Adjust (FAMIS 8445)

With the ISS OFF, I adjusted the operating current of the HPO DBs. Changes are summarized in the below table; a screenshot of the PSL Beckhoff main screen is attached for future reference.

| Operating Current (A) | ||

| Old | New | |

| DB1 | 50.9 | 51.1 |

| DB2 | 53.3 | 53.5 |

| DB3 | 53.3 | 53.5 |

| DB4 | 53.3 | 53.5 |

I did not adjust the operating temperatures of the DBs. The HPO is now outputting 154.2 W and the ISS is back ON. The completes FAMIS 8445.

PSL Power Watchdog Reset (FAMIS 3673)

I reset both PSL power watchdogs at 16:23 UTC (9:23 PDT). This completes FAMIS 3673.

Attached is the updated trend of the HPO pump diode currents since we began adjusting the currents on a weekly basis. The flat spot in the beginning of September was a 2 week period of no adjustments as we swapped the NPRO laser in the 35W FE. To date, the currents are increasing linearly (minus the period in late May and early June when we swapped the failing DB1 for a spare).

Yesterday, prior to walking down the Y-beam manifold from in-chamber to inspect the Cryo baffle and alignment beams, Travis wiped some surfaces. When he wiped the Gate Valve 1 trough he picked up numerous macroscopic bits that I'd guess are viton from the o-ring which have shed during cycling. He also picked up what I will assume is black oxide (seems like what we've seen elsewhere). These surfaces haven't been touched in many years, so I'm not really surprised at these findings. See picture below.

This looks to me to be residual "carbon black" (MT N990) which is added to the Viton. It looks nasty but is benign from an (out-gassing) contamination point of view.

[Gregg, Jason, Aidan, TVo, TJ, Jon]

We located the correct Siskiyou 2" mirror mounts (IXM200) for the HAM4 work this morning. Thanks to Corey, who pointed us to two spares that were in the optics lab and were Class A cleaned.

Recall that yesterday, we discovered that the 2" mirror mounts that we had been given for mounting the DCBS were DLC mounts, not Siskiyou mounts. The DLC mounts put the optic height 0.5" higher than the Siskiyouu mounts do.

We removed the existing DLC mounts that were added yesterday and removed the dichroic beam splitters (DCBS - T = 300ppm for 1064nm at normal incidence [MI1000]) from these mounts. In doing so, we noted that both DCBS had visible particulates on them. Additionally, the DCBS on the X-arm had a small smudge on the optic and a chip in the barrel. We decided to proceed with the install of the new Siskiyou mounts and assess the action to be taken with the optics after install.

The ITMY laser was turned on again and we were able to use the leakage of this laser through SR2 to align the Y-arm DCBS. We pitched it down a considerable way and confirmed that the reflection from it was dumped on the scraper baffle well below the optical axis.

We adjusted the SR3 alignment to get a ghost beam coming off HWS STEER M1 aligned through the HWSX optics. We installed the new Siskiyou mount on the existing pedestal and noted the height was approximately 6mm higher than neighbouring optics. The pedestal and mount were shifted towards the in-vacuum lens by approximatley 3" (new position is shown in the attached image). Original assembly shown in D1101083-v2.

We centered the DCBS on the laser beam and then adjusted the pitch so that the return beam was dumped on the scraper baffle. For reference, we measured the return beam as it hit HWSX STEER M3 and it was 10mm below the incident beam on that optic. Since the DCBS is approximately 12" away, this puts the reflected beam angle at -1.9 degrees. This put the return beam about 45mm down from center on the HWS SCRAPER BAFFLE.

The optical mounts are installed and aligned, however, the optics themselves almost certainly need to be cleaned if not replaced. For reference, the HWSX DCBS sees about 300mW of 1064nm light (at about 25W input power into the IFO). The HWSY DCBS sees about 100nW.

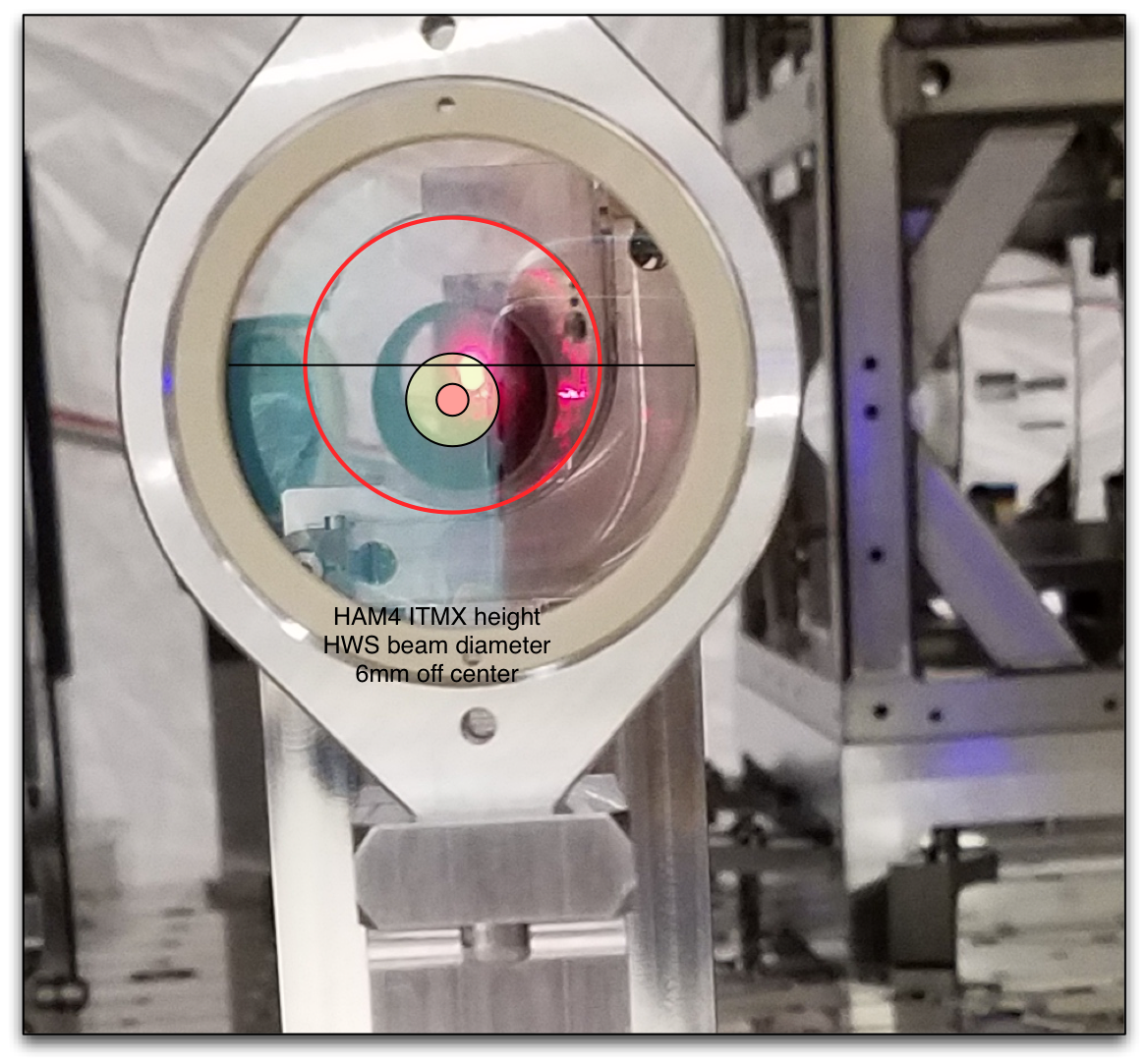

Here's an image of the estimated HWS beam size (about 16mm diameter) and IFO beam size (about 5mm diameter) at the DCBS. The beams are centered about 6mm below the center of the optic. That leaves about 19mm from the center of the beam to the edge of the optic, or about 2.4 beam radii.

You can see a slight smudge near the center, just off to the South-West (lower left) in this orientation.

Pictures of HWSX STEER M1 install

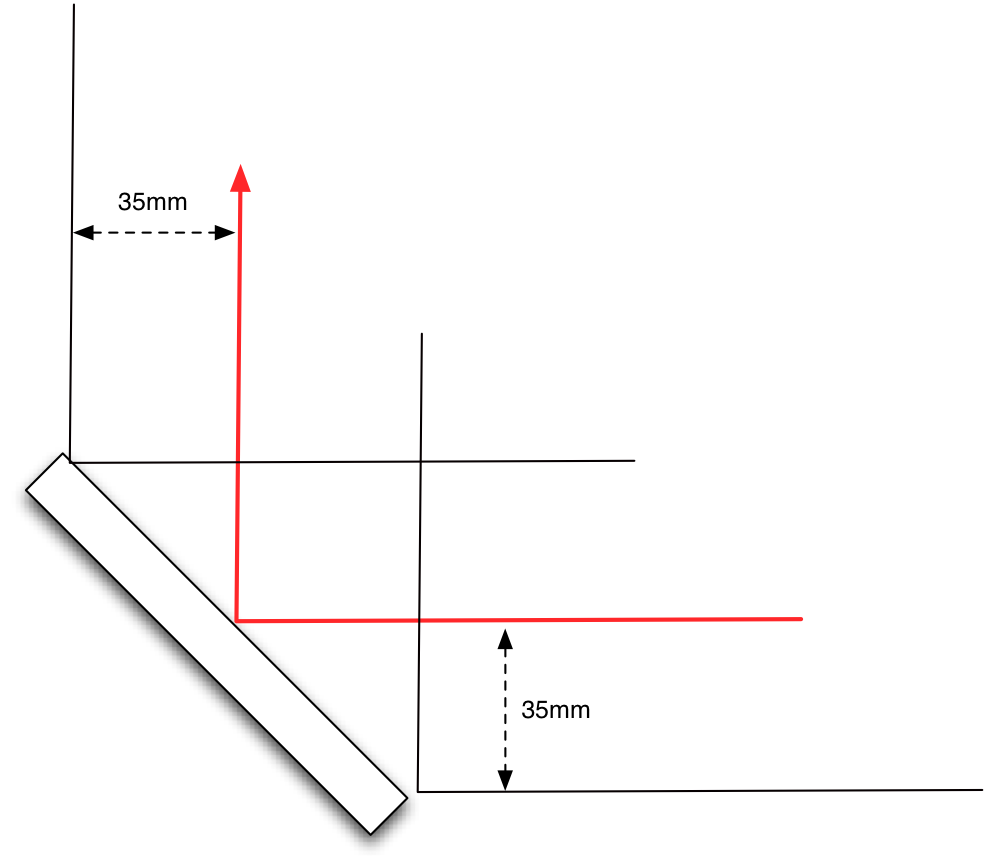

We confirmed that the incident beam and the reflected beam were approximately 35mm from the edge of the aperture (as viewed from each direction).

I added an FRS ticket for the particulate issue: https://services.ligo-la.caltech.edu/FRS/show_bug.cgi?id=9280