(Cheryl, Corey, Ed, Keita)

Items Removed

The following assemblies/items were removed today & bagged/tagged:

ROM RH4:

- 2" BS (90/10) only

ROM RH5:

- Siskiyou Mirror Mount

- Post

NOTE: The 2" HR ("M-38-UNP-53") & Black Glass dump for this one was installed on ROM RH4

ROM RH6:

- 2" HR Mirror ("ATF PL M-17-P")

- Siskiyou Mirror Mount

- Black Glass Beam Dump assembly for mirror mount

- Post

ROM LH2:

- 2" HR Mirror

- Siskiyou Mirror Mount

- Black Glass Beam Dump assembly for mirror mount

NOTE: A V-Black Glass Dump was installed on the post for LH2.

Misc:

- (2) Fork Clamps Removed

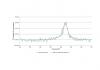

Tightening IM3 Assembly Screws

Here is a note Ed wanted me to take while Keita tightens:

1) Tightened screws on top of IM3, and had this:

- Pit: No Change

- Yaw +10 uradians

2) Tightened 1/4-20 bolts (on sides, OSEM plates, etc.), and had this:

- Pit: No Change

- Yaw +70 uradians

- IMG-2655 shows overhead view of the black glass beam dump that was added (9:00 position in photo)

- IMG-2656 shows the HR optic w/black glass which replaced the 90/10 BS that was there before

- IMG-2658 shows the vacant space where there were two HR mirrors (one of which resides where the BS used to)

- IMG-2659 is a close up of the mirror that replaced the BS