M. Todd, S. Dwyer

I've been polishing up the analysis of models estimating the various couplings of TCS powers to substrate and surface defocus in the test masses. This can be used to test the validity of the HWS estimate of the absorption in the ITMs. For reference, assuming the HWS are correct in their calibration of what the substrate defocus is in the test masses [ITMY = 63.5uD, ITMX = 54.5uD], and that my model is right for the coupling of substrate defocus from absorbed Watts of arm power [250 uD/W], then we have rougly 254mW of absorbed power in ITMY and 218mW of absorbed power in ITMX. Naively this seems too much, but I wanted to see if this could be consistent with measurements of the arm cavity Gouy phase.

Surface Defocus from Ring Heaters -- Models and Measurements

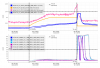

From both models and measurements, we have a much better idea now of how the ring heaters couple into test mass surface defocus. Fitting the HOM spacing in the YARM as a function of different ETMY ring heater powers, we obtain an estimate of the coupling factor of ETM ring heater power to surface defocus [1.53 +/- 0.2 uD/W]. The SQZ dataset which was taken at 2W, can be used to estimate the ring heater coupling as well because the HOM spacing of the YARM is purely the combination of the completely cold RoC (from galaxy) from the test masses plus the defocus from the ETMY ring heater (assuming negligible defocus from absorbed arm power) . The YARM cavity g-factor in the 2W state with ETMY ring heater on (2.93W) is calculated to be 0.8345. The cold cavity g-factor (without ring heaters or absorbed power) is calculated to be 0.8235. This yields a coupling factor (again, assuming negligible defocus from absorbed arm power) of ETM ring heater to surface defocus of 1.77 uD/W , which is almost within the bounds of the estimate above. These are both consistent, however, with modeled coupling factor [2.0 uD/W] with some imperfect efficiency of the ring heater heating. We can do the same analysis for the XARM with the caveat that we must assume a known ratio of the coupling factors of ring heater to surface defocus of the ITM and the ETM (we did not have to do this for the YARM because ITMY has no ring heater power). Assuming the coupling factors have a ratio beta = 1.73 (ITM_coupling/ETM_coupling) and that the XARM cavity g-factor measured in the 2W state is 0.8373 then the inferred coupling factor for the ETMX ring heater to surface defocus is 1.80uD/W. This is consistent with the inference for ETMY. These values are consistent enough with each other that we can use them in the next inference, I believe.

| Inferred ETM Ring Heater Coupling from YARM HOM spacing at 2W [SQZ dataset] |

1.77 uD/W |

| Inferred ETM Ring Heater Coupling from XARM HOM spacing at 2W [SQZ dataset] |

1.80 uD/W |

| Inferred ETM Ring Heater Coupling from YARM HOMs fit of ETMY Ring Heater Settings Sweep |

1.53 uD/W |

| Modeled ETM Ring Heater Coupling with 100% efficieny assumed |

2.03 uD/W |

Surface Defocus from Absorbed Arm Power to Infer the Circulating Power in the Arms

Since now we have a good understanding of the ring heater's contribution to the surface defocus and cavity g-factor shift, we can infer the absorbed arm power's contribution using the cavity g-factor measured at 60W. The measured cavity g-factors, calculated from the HOM spacings, were 0.8173 for the XARM and 0.8228 for the YARM. Assuming all the absorptions reporteed by galaxy are correct we can use the measured cavity g-factor shift along with modeled coupling factors of absorbed arm power to defocus to infer the arm power (JAAPE = Just Another Arm Power Estimate). The absorptions for the ITMs are 0.5 ppm, ETMY is 0.21ppm and ETMX is 0.20ppm. If we assume the coupling factors for ring heater surface defocus from the SQZ dataset and the modeled coupling factors of absorbed power to surface defocus, we get an arm power estimate of 283kW in the YARM and 481kW in the XARM. These indicate that the true absorptions in the test masses are most likely different from the galaxy numbers, as these arm powers are not consistent with the arm gain inference of the arm power, especially for the XARM.

Surface Defocus from Absorbed Arm Power to check the HWS Estimate of Absorbed Arm Power

We can repeat the above analysis, but instead assume nothing about the absorptions, and instead use the HWS estimates of the absorbed power in each input test mass. Then we can infer what the absorbed powers are in the end test masses to have measured the cavity g-factor as calculated from the HOM spacing. For ITMX, the HWS estimate an absorbed power of 218mW, and for ITMY the HWS estimates 254mW of absorbed power. To have measured a cavity g-factor in the XARM as mentioned above, with the HWS estimate of ITMX absorbed power, the absorbed power in ETMX would have to be 121mW. For the YARM measurement, using the HWS estimate of the ITMY absorbed power, the ETMY absorbed power would need to be -54.5mW. This indicates the HWS may be wrong, especially the ITMY HWS, as it is physically impossible to have measured the cavity g-factor that we did and simulataneously have that much absorbed power in ITMY (assuming the coupling factors from my model are correct).

Summary

Using two different methods, I've come a round-about-way to say that it is unlikely our absorptions are exactly as reported in galaxy, but that the HWS may not be giving us any better estimate (of the absorbed power). I am currently trying to calibrate the HWS using independent measurements, but more work is needed on that. Despite the ITMX HWS SLED just recently being replaced (we thought it was miscalibrated because it was dying), the defocus reported by the two HWS for CO2 heating differs by almost a factor of 2!

I am not well versed in HWS code and I'm not totally sure how these values of defocus are calculated from the deflection of each partitioned beam but these errors may be mis-identification of the position of the centroid.

This is a table of parameters describing the various coupling factors from the modeling.

| Parameter |

Value [uD/W] |

| ITM Coating Absorption to Substrate Lensing (AiL) |

250 |

| ITM Coating Absorption to Surface Defocus (AiS) |

-38 |

| ITM Ring Heater to Substrate Lensing (BiL) |

-27 |

| ITM Ring Heater to Surface Defocus (BiS) |

3.5 |

| ETM Coating Absorption to Surface Defocus (AeS) |

-28 |

| ETM Ring Heater to Surface Defocus (BeS) |

2.0 |

This is a summary table using the above modeled parameters

| HWS Estimate of ITM Absorbed Powers |

ITMY = 254mW, ITMX = 218mW |

| Inferred Arm Powers using galaxy absorptions |

XARM = 481kW, YARM = 283kW |

| Inferred ETM absorbed powers from HWS Estimates |

ETMY = -55mW, ETMX = 121mW |

Conclusion: we have much more confidence in our models of various coupling factors thanks to measurements of the ring heaters effect on surface defocus, however we do not have a very good estimate of the absorbed powers or absorptions.

The serial numbers that are mentioned as the satamps are actually the coil drivers for JM1 and JM3.

Serial numbers for the satamps that were installed at this time were S2500406 for JM1/JM2, and S1200173 for JM3/PM1