I performed the weekly PSL FAMIS tasks this morning.

HPO Pump Diode Current Adjust

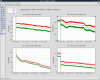

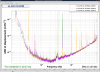

All pump diode currents were increased by 0.1A, new and old currents summarized in the table below. The first attachment shows a 15 day minute-trend of how the DBs have decayed since the last current adjustment, while the 2nd is a screenshot of the main PSL Beckhoff screen for future reference.

| Operating Current (A) | ||

| Old | New | |

| DB1 | 48.6 | 48.7 |

| DB2 | 51.5 | 51.6 |

| DB3 | 51.5 | 51.6 |

| DB4 | 51.5 | 51.6 |

I looked at and optimized the DB operating temps as well. I changed the temps on all the diodes in DB1 from 28.0 °C to 29.0 °C; the operating temps of the other 3 DBs remained unchanged. The HPO is now outputting ~157.7 W. This completes FAMIS task 8427.

PSL Power Watchdog Reset

I reset both PSL power watchdogs at 15:35 UTC (8:35 PDT). This completes FAMIS task 3655.