Without the ALS green beam leaking onto the HWS table, it is a much more laborious exercise to align the HWS beams. However, the process involves these steps:

- Find the HWS return beam:

- Coarsely align the HWS beam to the center of the first in-vacuum lens by using an IR camera and counting the number of turns on the upper periscope mirror required to scan the beam across the full aperture of the in-vacuum lens, then move it half that amount

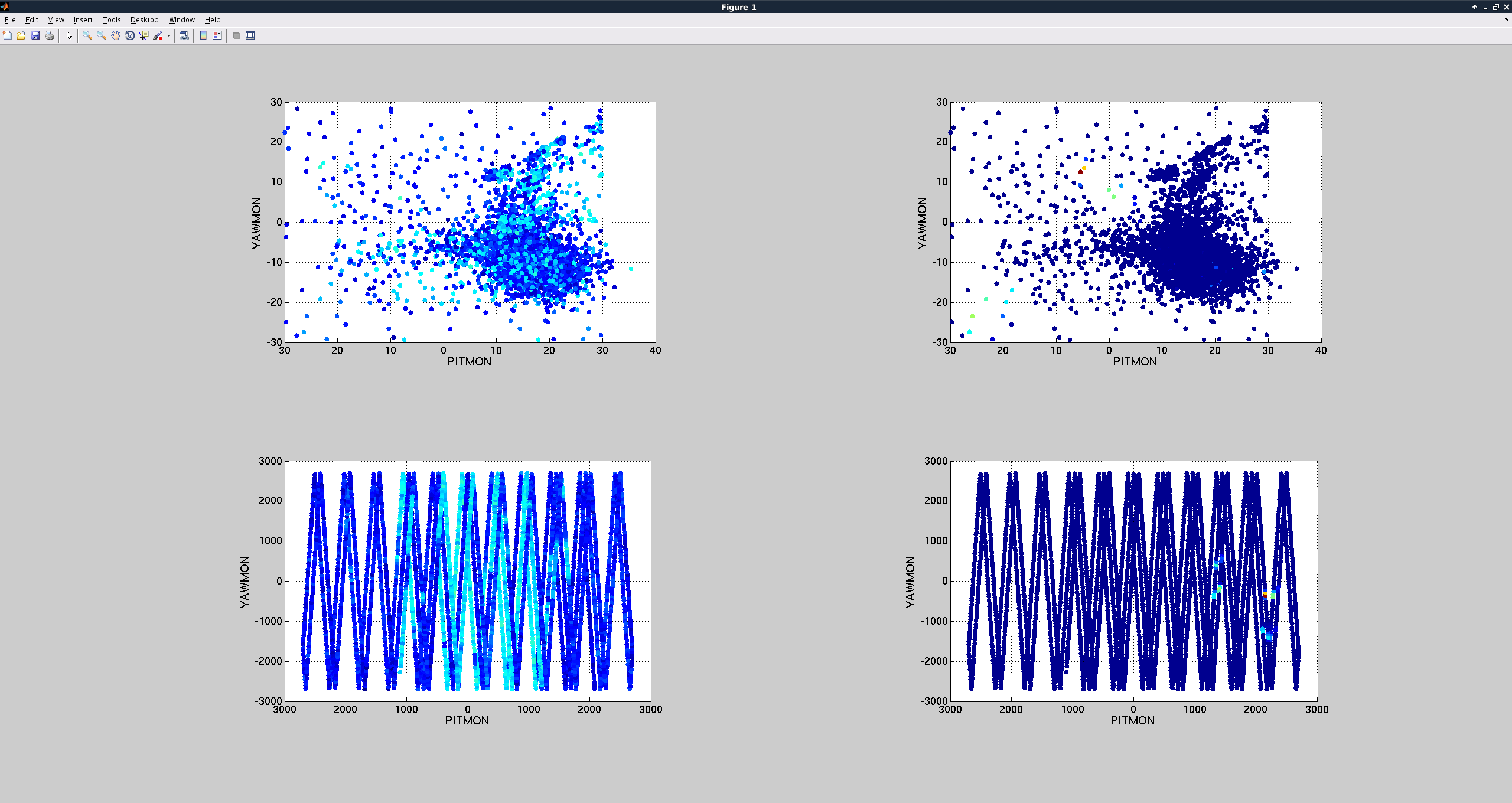

- Scan SR3 slowly +/- 2mrad in PITCH and YAW and measure the return power on the HWS CCD camera. The oscillation frequencies of PIT and YAW should not be multiples of each other. (Make sure SR3 cage servo is off).

- Once HWS return beam is located, gradually return SR3 to its nominal IFO-aligned position while using the upper periscope mirror to keep the HWS return beam on the HWS CCD

- Once SR3 is in its nominal position, use the upper and lower periscope mirrors to align the HWS return beam so that it remains on the HWS CCD and also is centered on the pre-aligned irises on the table (pre-aligned to the outgoing beam). To do this, open and close the iris and note the diameter at which the return beam is occluded. Iteratively adjust the upper and lower periscope mirrors (while keeping the return beam on the HWS CCD) so that this diameter is decreased.

- Align the last HWS mirror so that the return beam is centered on the HWS CCD

- Move the HWS to the conjugate plane of the ITM: Inject a YAW oscillation into the ITM and measure the beam displacement oscillation on the HWS CCD. Adjust the position of the HWS until this is minimized.

As of today, we've injected an SR3 oscillation a few times and successfully located the HWSY return beam but not the HWSX return beam. At this point, my suspicion is that ITMX has not returned to its nominal pre-vent alignment with enough precision to get a return beam at all on HWSX. We currently have not ITM OpLevs to check this.

This morning, we are going to proceed with getting the HWSY return beam aligned while Jenne and Co. see if they can get the DRMI aligned.

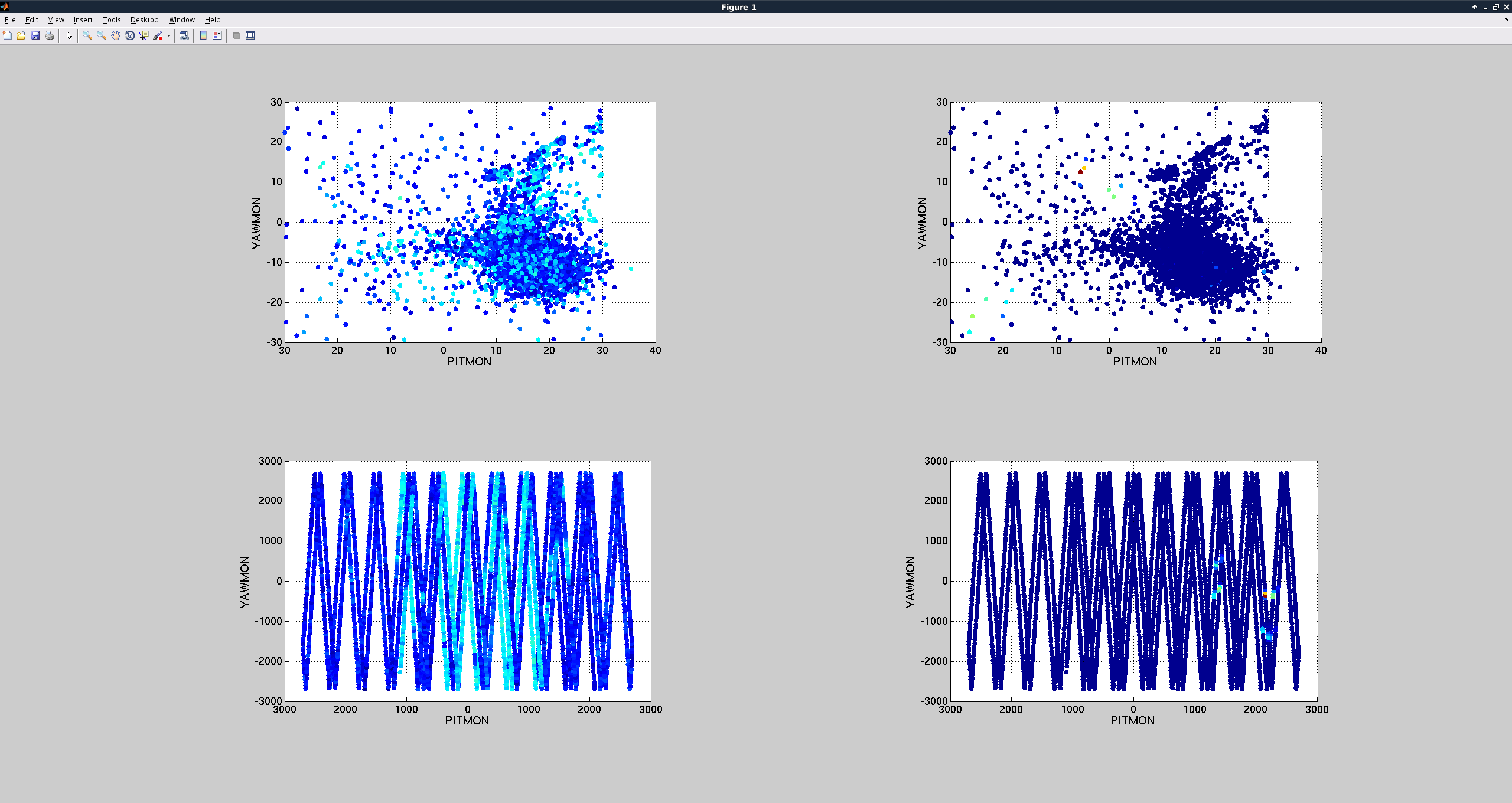

Bottom plots show HWSX (left) and HWSY (right) return intensities vs SR3 PIT and YAW SR3-M1-TEST input values