Evan G., Jeff K. Summary: The calibration measurement data that was collected yesterday has now been analyzed using our Markov Chain Monte-Carlo (MCMC) methods. We detail the results below. Nothing abnormal was found, and we find that the time varying factors can track changes in sensing gain and coupled cavity pole and actuation coefficients. Details: We analyzed the data collected during yesterday's calibration measurements, see LHO aLOG 35849. We have simplified the process for analyzing the data; rather than running two separate Matlab script to generate the MCMC results, we can now run just one script to get the final model results. For the sensing function, we run ${CALSVN}/trunk/Runs/O2/H1/Scripts/SensingFunctionTFs/runSensingAnalysis_H1_O2.m while for actuation, we run ${CALSVN}/trunk/Runs/O2/H1/Scripts/FullIFOActuatorTFs/analyzeActuationTFs.m. Note that for the actuation calibration script, we have not yet converted it to an IFO agnostic script. Once it is converted, this script will be renamed. Below are the table of values and their associated uncertainties for yesterday's measurements. Also, for comparison, are the modeled values from the reference measurement 3 Jan 2017: Reference Value MAP (95% C.I.) MAP (95% C.I.) 2017-01-03 2017-01-03 (MCMC) 2017-04-27 (MCMC) Optical Gain K_C [ct/m] 1.088e6 1.088e6 (0.0002e6) 1.124e6 (0.0002e6) Couple Cav. Pole Freq. f_c [Hz] 360.0 360.0 (7.6) 343.4 (2.6) Residual Sensing Delay tau_C [us] 0.67 0.67 (6.7) -1.8 (1.8) SRC Detuning Spring Freq. f_s [Hz] 6.91 6.91 (0.1) 7.4 (0.04) Inv. Spring Qual. Factor 1/Q_s [ ] 0.0046 0.046 (0.016) 0.009256 (0.0069) UIM/L1 Actuation Strength K_UIM [N/ct] 8.091e-8 8.091e-8 (0.2%) 8.0818e-8 (0.18%) PUM/L2 Actuation Strength K_PUM [N/ct] 6.768e-10 6.768e-10 (0.02%) 6.795e-10 (0.08%) UIM/L3 Actuation Strength K_TST [N/ct] 4.357e-12 4.357e-12 (0.02%) 4.537e-12 (0.07%) UIM/L1 residual time delay [usec] n/a n/a 29.1 (35.5) PUM/L2 residual time delay [usec] n/a n/a 7.7 (3.1) TST/L3 residual time delay [usec] n/a n/a 10.2 (1.8) These values are derived from MCMC fitting to the data values. The attached plots show these results for the sensing and multiple-stage actuation functions. We have added a new feature to the MCMC analysis, modeling the residual time delay in actuation. We expect to have zero usec of residual time delay, provided the model accurately captures all dynamics of the actuation. Deviations from zero can reveal un-modeled dynamics. For example, the PUM and TST residual time delays are inconsistent with zero usec, but we expect that this is due to imperfect modeling of the complicated violin resonances of the quad suspension. The time varying factors are doing a good job tracking the changes between the reference model and the currently measured parameters (see time varying factors summary page). For reference, the parameter files were used as follows: ${CALSVN}/trunk/Runs/O2/H1/params/2017-01-24/modelparams_H1_2017-01-24.conf (rev4401, last changed 4396) ${CALSVN}/trunk/Runs/O2/H1/params/2017-04-27/measurements_2017-04-27_sensing.conf (rev4596, last changed 4596) ${CALSVN}/trunk/Runs/O2/H1/params/2017-04-27/measurements_2017-04-27_ETMY_L1_actuator.conf (rev4596, last changed 4596) ${CALSVN}/trunk/Runs/O2/H1/params/2017-04-27/measurements_2017-04-27_ETMY_L2_actuator.conf (rev4596, last changed 4596) ${CALSVN}/trunk/Runs/O2/H1/params/2017-04-27/measurements_2017-04-27_ETMY_L3_actuator.conf (rev4596, last changed 4596)

A typo in the reference values for 1/Q_s above. It should be 0.046 (not 0.0046 as typed above).

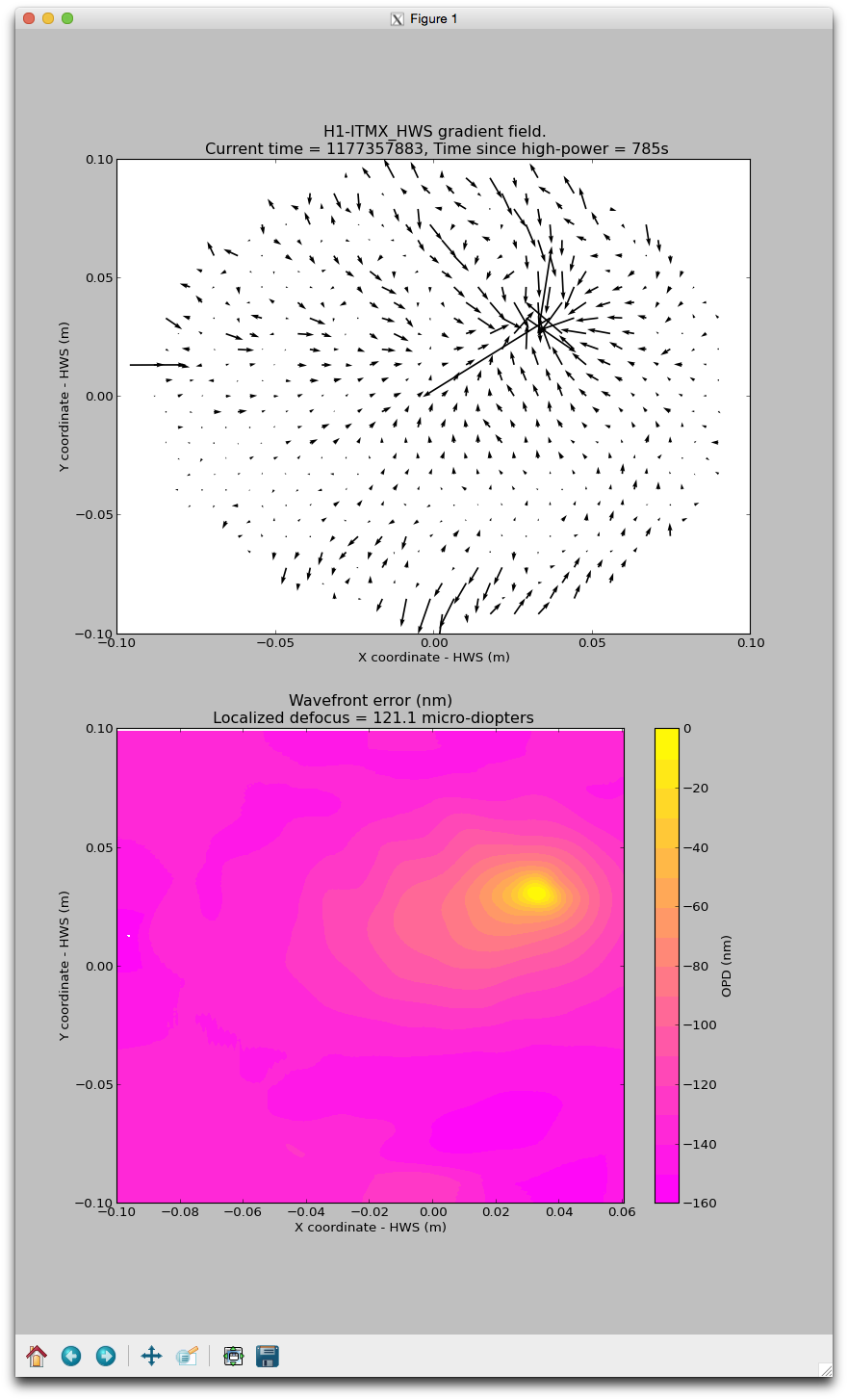

For a bigger picture look at these 2017-04-27 actuation function measurements, I attach a plot of the model against measurement *before* dividing out the frequency dependence. This helps discern what the overall phase of the actuator stages should be relative to each other during O2.