This morning I saw some noise in the 60-200Hz area on DARM that lastest for a few minutes and then went away. I came back about an hour later, and an hour after that as well. The SEI BLRMS are clearly coincident with this breathing noise, and with the slight drop in range. Robert is thinking this may be tilling or truck traffic on the Hanford site.

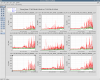

I attached a plot of some of the BLRMS. It is seem the most in the corner station, but the ends see it a bit as well.

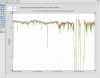

Robert and I watched with the roof camera and saw that there are about 5 large trucks that will pass the site on Route 10 within a few minutes of each other. The trucks are the kind that haul dirt/gravel/rocks and have two trailers (excuse my lack of truck terminology there). As these trucks pass, noise is DARM is clearly seen, and in the 3-10 and 10-30Hz SEI BLRMS as well. This much ground motion caused by trucks is abnormal, and we are hoping that it was a only for today. Our range has definitely seen this ground motion and it is show as going from 48-68Mpc for the last 3 hours, and is also seem in the previous lock ending around 16UTC. I attached a 24hr trend of some of the SEI BRLMS and range attached.

While I was watching for trucks to go by, I also saw a FedEx delivery truck show up on site. As this truck made the turn from Route 10 onto our driveway, it raised DARM similarly like the above trucks. On the straight the noise dropped, then the turn toward the LSB it rose again, and finally it had to backup and the noise popped back up.