Krishna,

The location of the c-BRS is shown in the attached map, indicated by the green '+'. The center of the instrument is very closely aligned with the center of the ITMX BSC chamber along the x direction and is located ~ 46 cm (18 inches) from the horizontal beam between the piers (seen a little below the green + sign).

c-BRS Locking Instructions

The attached screenshot shows the MEDM screen to control c-BRS. The control flow is described in T1600325. The two interferometer cavities are locked using the PZT1 and PZT2 filter boxes. The second cavity feedback signal is used to apply damping to the beam-balance. If the outputs of the PZT control signals (top right) look railed, this indicates that the beam-balance has drifted out of the range of the piezos. We can reset the range simply by locking to a different fringe as described below.

1. First, turn off damping, by setting the gain of the DAMP filter box to 0.

2. Open PZT1. Set Gain to 0. The ramp time should be set to 3 s.

3. Hit 'CLEAR HISTORY'. Now turn the PZT1 Gain back to 0.25. First cavity should be locked.

4. Open PZT2. Set Gain to 0. The ramp time should be set to 3 s.

5. Hit 'CLEAR HISTORY'. Now turn the PZT2 Gain back to 0.25. Second cavity should be locked.

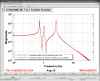

6. Wait at least 30s and then set the DAMP Gain to 0.1 This sets the Q of the beam-balance to ~20, as opposed to the natural Q of ~150.

Note that if we know the direction of the drift, the Piezo offset can be set to take advantage of that fact. Currently the Piezo 1 drifts negative hence the Piezo 1 offset is set close to the positive maximum (2^17 ~ 130,000 cts) and vice versa for Piezo 2. I expect that this drift will go away in a few days time and then we will just have the normal daily temperature modulation, in which case the PZT offsets could be set to 0.