This morning before maintenance really took off, we tried switching blends on all of the BSCs, while the IFO was still locked. Contrary to my findings a couple weeks ago (alog 23610), it now seems like it's possible to switch blends while the IFO is locked and not break lock. We started out carefully, switching only the ETMs, one at a time, then the corner station ISIs. We then tried a little faster, doing the corner station all at once, then both ETMs. Finally, we switched all chambers all at once. For each of these tests, we switched from our nominal 90mhz blends to the 45mhz blends then back. The lock survived each switch, although the ASC loops would ring up some, especially when we switched the ETMs. The corner station ISIs didn't seem to effect ASC as much.

The only IFO difference I know of between the last time I looked at this and now is that Hugh went down and recentered the ETMY's T240s. Environment is also different today, with pretty quiet winds (<10mph) and only moderate microseism (rms < .5 microns).

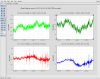

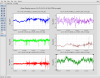

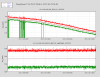

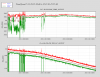

The attached trends are for the ASC D/C Hard, D/C soft, ETM oplevs and corner station oplevs. Similar to what I found a while ago, ETMY seemed to have the biggest effect on the IFO (based on what we saw on the ASC foms in the control room), although the ITMY oplev actually moved more. Still, the oplevs didn't see more the about 1.5 microradians motion at any point.

You can also tell what blends were running on the traces based on the eye-ball rms of the ASC signals. The 90mhz blends don't filter out the microseism which is moderate today, so the ASC pitch signals get noisier. This is also visible on the oplevs.

This test makes us ~80% confident we can probably switch blends while locked. With caveats about the current environment not being very extreme. If it;s windy or the microseism is high, the answer could change.