Sheila, Jenn{e,ie}, Robert

Continuing efforts to find out how to minimise the beam from PR2 clipping on the scraper baffle, as investigated in alogs #[77870, 77968, 77988, 81329].

At the start Sheila and Jenne agreed we should try to find the two extrema where the beam going from PR2 to PR3 clips the scraper baffle and the one going from PRM to PR2 clips the scraper baffle.

Sheila measured the PR2 Y2L gain by minimising the transfer function from PR2 yaw position to PRCL_OUT, while injecting a line at 30Hz as in [LHO alog #82251] entry.

New P2L: -0.36 from the measurement I did the other week.

New Y2L: -6.25

Now the aim was to move the spot on PR2 to find where each beam hitting it clips the PR2 scraper baffle.

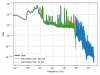

Move PR3 in negative yaw while monitoring LSC-POP_A_LP_NORM (pop power) and PR2 inmon on M1 to check ASC is not changing much to ensure we do not unlock the IFO. Every 13 PR3 microradians is 0.5mm.

We stepped 96 uradians to 68 microradians on PR3 yaw and corrected pitch down every time we dipped too low on LSC-POP or PWR_CIRC, every 1 microradian or so jenne moved picomotor A_8 (the one that aligns to both the ALS PDs and the LSC-POP PDs) by -50 counts to bring back the LSC POP alignment.

I measured our new Y2L to be -5.75 gain at this new value (moved 1 mm according to Jenne's script). Robert looked at the beam reflected off the baffle to the viewport at this point as a check of the power in it relative to our nominal position for the PR2 beam spot.

We kept going after this point but lost lock after moving about 8.5 microradians.