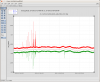

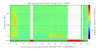

Here are the observed H1-L1 coherences as of October 12, 2015, as calculated by stochmon:

https://ldas-jobs.ligo.caltech.edu/~thomas.callister/stochmonO1/stochmon.html

Some plots attached.

100 mHz resolution. 1E-5 is the expected level of coherence due to uncorrelated noise.

Frequency, coherence

33.6 Hz, 1E-3

34.6 Hz, 2E-2

35.4 Hz, 1E-3

42.5 Hz, 6E-4 (barely above background, could be a noise fluctuation)

64.0 Hz, 2E-4 (barely above background, could be a noise fluctuation)

74.0 Hz, 5E-4 (barely above background, could be a noise fluctuation)

128.0 Hz, 1E-2

256.0 Hz, 2E-3

331.8 Hz, 3E-4 (barely above background, could be a noise fluctuation)

351.1 Hz, 4E-4 (barely above background, could be a noise fluctuation)

559.9 Hz, 2E-4 (barely above background, could be a noise fluctuation)

736.0 Hz, 3E-3 (23rd harmonic of 32 Hz)

1904.0 Hz, 2E-3 (119th harmonic of 16 Hz)

2160.0 Hz, 4E-4 (135th harmonnic of 16 Hz)

2376.0 Hz, 4E-3 (297th harmonic of 8 Hz)

2768.0 Hz, 7E-3 (173rd harmonic of 16 Hz)

2984.0 Hz, 7E-4 (373rd harmonic of 8 Hz)

3001.2 Hz, 1E-1 (calibration lines)

4928.0 Hz, 3E-3 (77th harmonic of 64 Hz)

5016.0 Hz, 3E-3 (627th harmonic of 8 Hz)

5144.0 Hz, 2E-1 (largest coherence, 643rd harmonic of 8 Hz)

5616.0 Hz, 2E-3 (351st harmonic of 16 Hz)

5624.1 Hz, 6E-3

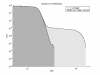

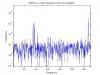

0.25 Hz, 4E-6 is the expected level of coherence due to uncorrelated noise.

Frequency, coherence

34.25 to 35.25 Hz, 1E-3

36 to 37 Hz, 1.5E-3

37.25 Hz, 2E-3

42.5 Hz, 2E-4

128.0 Hz, 3E-3

256 Hz, 6E-4

1904.0 Hz, 4E-4 (119th harmonic of 16 Hz)

3552.25 Hz, 2E-4

4163.75 Hz, 5E-3 Hz

4576.0 Hz, 2E-4 (143rd harmonic of 32 Hz)

5016.0 Hz, 7E-4 (627th harmonic of 8 Hz)

5144.0 Hz, 1E-1 (largest coherence, 643rd harmonic of 8 Hz)

5584.5 Hz, 2E-2

5655.5 Hz, 1E-3