STATE OF H1: No Observation Mode during this shift. Continue recovery from earthquake, but H1 appears to get lock (~72Mpc), albeit with some new issues (see below).

SUPPORT: Jenne, Sheila, Jeff K, Evan, & Stefan

SHIFT SUMMARY: Another shift of recovery. Evan & Stefan did some measurements on H1 & also some troubleshooting. Lock Acquisition is not optimum & we have a few issues:

- SRM saturations & watchdog trips (had it happen to me when I realigned SRM while tweaking in PRMI)

- Problem with Finding IR for ALS_DIFF (so one has to physically adjust the DIFF_OFFSET slider)

DAY'S ACTIVITIES:

- 9/13 @ 7:53utc Verbal_Log died on video5 (restarted on 9/14 @4:21)

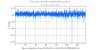

- 23:24: NOMINAL_LOW_NOISE (first time post-big-quake)

-

1:25 LOCKLOSS

- Restored SR3 Pitch value

- Had issues Finding IR a few times tonight

- During DRMI acquisition alignment/flashing looked bad

-

Locked PRMI & tweaked BS & PRM (did not do PR2)

- When realigning SRM it tripped its Software Watchdog (Jim also mentioned having SRM saturations. This is a new feature.)

- Will try PRMI again, and this time try PR2 (& maybe PRE3?)

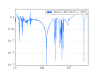

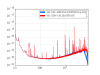

- Evan discovered high frequency noise for SRM

- 2:30 Went CER to power cycle (white button on back) of SRM Driver box (still high freq noise after power cycle)

- 5:28 NOMINAL_LOW_NOISE

- 5:36 Loading coefficients for hardware injection filter (jeff)

-

6:02 Lockloss

- Had to help FIND_IR for ALS_DIFF

-

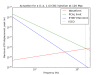

6:36 NOMINAL_LOW_NOISE & Evan/Stefan starting OMC measurements

- Remember to Close OMC REFL Beam Diverter before going to OBSERVATION!!!

Addendum Notes

Bubba will address Chiller Yard alarm noted Sat night when he's in on Monday (change alarm setting?)

H1 Problems of the day:

-

These are items Jim mentioned to me:

- HAM5 ISI Watchdog rogue excitation watchdog was not trivial to reset

- SRM saturating and tripping HAM5ISI: This is a new feature

- ALSy problems which were remedied by PR2 tweaks

SDF Diffs

- optical align offsets changed to not monitored for: etmx, itmx

-

PR3 was clicked to NOt Monitored, but sheila and I decided we should keep monitoring this channel

- Idea is to Monitor SUS biases for optics we rarely touch (so that if they are touch, we get an SDF notification)

- SUSIM: Cheryl changed alignment and then Jim changed back. So I will go back to ACCEPTING their alignment in SDF(since these aren't changed much and we can monitor when they are changed)

SR3 Cage Servo

Locked H1 without this servo engaged (SR3 was saturating). Sheila was able to slowly engage this while in lock. The H1:SUS-SR3_M1_OPTICALALIGN_P_OFFSET SDF setpointpoint is 563.7, but to get this servo to go, it was moved to 562.2 (Sheila called this a "hot" state for SR3). For future locks we want to go back to the "cold" value of 56.7. This was done after the 1:27 Lockloss.