[Sheila, Anamaria, Jenne, Cheryl, Dan, Evan. Richard via phone]

SR3 glitches are still causing us grief. This is a continuation of the story started last night (alog 21046), and worked on earlier in the day (alog 21062). After some heroic efforts, we have determined that we cannot lock in this state.

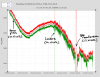

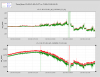

To prove to ourselves that indeed it was a problem with the analog actuation chain we investigated turning different pieces of the analog electronics off. The first attached Dataviewer screenshot shows the NOISEMON channels of the SR3 M1 stage throughout this investigation. When the local damping is on, we cannot see the glitches very clearly in the noisemon channels - but we do see them in the voltmon channels (The second attached screenshot shows that the T2 voltmon channel does in fact see the glitches, so it's not a broken monitor). When the local damping is off, we only see the glitches in the noisemon channels.

-

A: 04:57 UTC we turned off the local damping (M1 OSEMs and "cage servo"), but left the DC alignment. After this we see significantly more noise in the M1 T2 NOISEMON than the other M1 channels.

-

B: 05:41 UTC we take SR3 to safe mode (i.e., we remove also the DC alignment bias on the M1 actuators). Glitches seem to be gone?

-

C: 05:45 UTC we power cycle the AI chassis for SR3 (which is shared with the OMC, so the OMC was first brought to safe) and the top coil driver chassis that drives T1, T2, T3 and __. After this we restore SR3 to aligned, but no local damping. Noise isn't as good as other channels, but looks better than earlier.

-

D: 06:07 UTC we turn off the AI chassis for SR3 and OMC. Glitches and noise seem to be gone.

-

Around 06:20 UTC we swap out the AI chassis (removed S1104370) with a spare borrowed from the H2 storage racks (at Richard's recommendation). We put in S1108081.

-

06:24 we are back from swapping, and the new AI chassis is turned on. Glitches seem to still be gone.

-

E: 06:26 UTC we restore SR3 alignment and local damping.

Since we do not see the glitches when the AI chassis is powered off, we infer that the noise is not generated in the coil driver board. (Note that we also borrowed a triple top coil driver chassis from the H2 storage racks, S1100192, but did not swap it in since we don't think the noise is coming from there). We have not, however, determined whether the noise is coming from the AI board (probably not, since it's still there after a swap?) or the DAC.

We tried a few times to lock the IFO after the AI board swap, but we were continually losing lock before the CARM reduction is complete. Lockloss investigations showed that the problem for most of these was SR3 motion.

At this point, we have determined that we need more expert brains to have a look at the analog electronics. The owl operator shift has been cancelled, since there will be no more full IFO locking happening until this problem is resolved.

The work has been completed. The IOC is installed in h1fescript0. It will start at system boot. Dave has put the daq changes in such that it will be captured in the frames after the daq restart.