It tripped at Nov 14 2014 03:48:32 UTC, which is 19:48:32 local time yesterday.

It tripped at Nov 14 2014 03:48:32 UTC, which is 19:48:32 local time yesterday.

I noticed while walking by that air currents (from my passing) caused the curtains to swing free and then thump on the box. This doesn't seem good. The curtains could likely be tied back, easy. Or maybe the cleanroom should be moved, a bit harder.

Seems like the temperature was already good-ish as of 18:00 or so yesterday.

Doug will rezero SR3 optical lever around 10am The beam balance is misbehaving, Krishna will be here Tuesday to investigate PEM cabling at end Y Ken moving AC outlets at end X Jeff and Andres packing and removing tooling at end X and end Y

Looks like an unwarranted glitch on the actuator. The CPS aren't moving before the trip. The GS13 respond quickly (hard to tell if this is cause or effect) but again there is no preamble.

model restarts logged for Thu 13/Nov/2014

2014_11_13 09:48 h1ioppsl0

2014_11_13 09:48 h1psldbb

2014_11_13 09:48 h1pslfss

2014_11_13 09:48 h1psliss

2014_11_13 09:48 h1pslpmc

restart of h1psl0 models during beckhoff chassis repair.

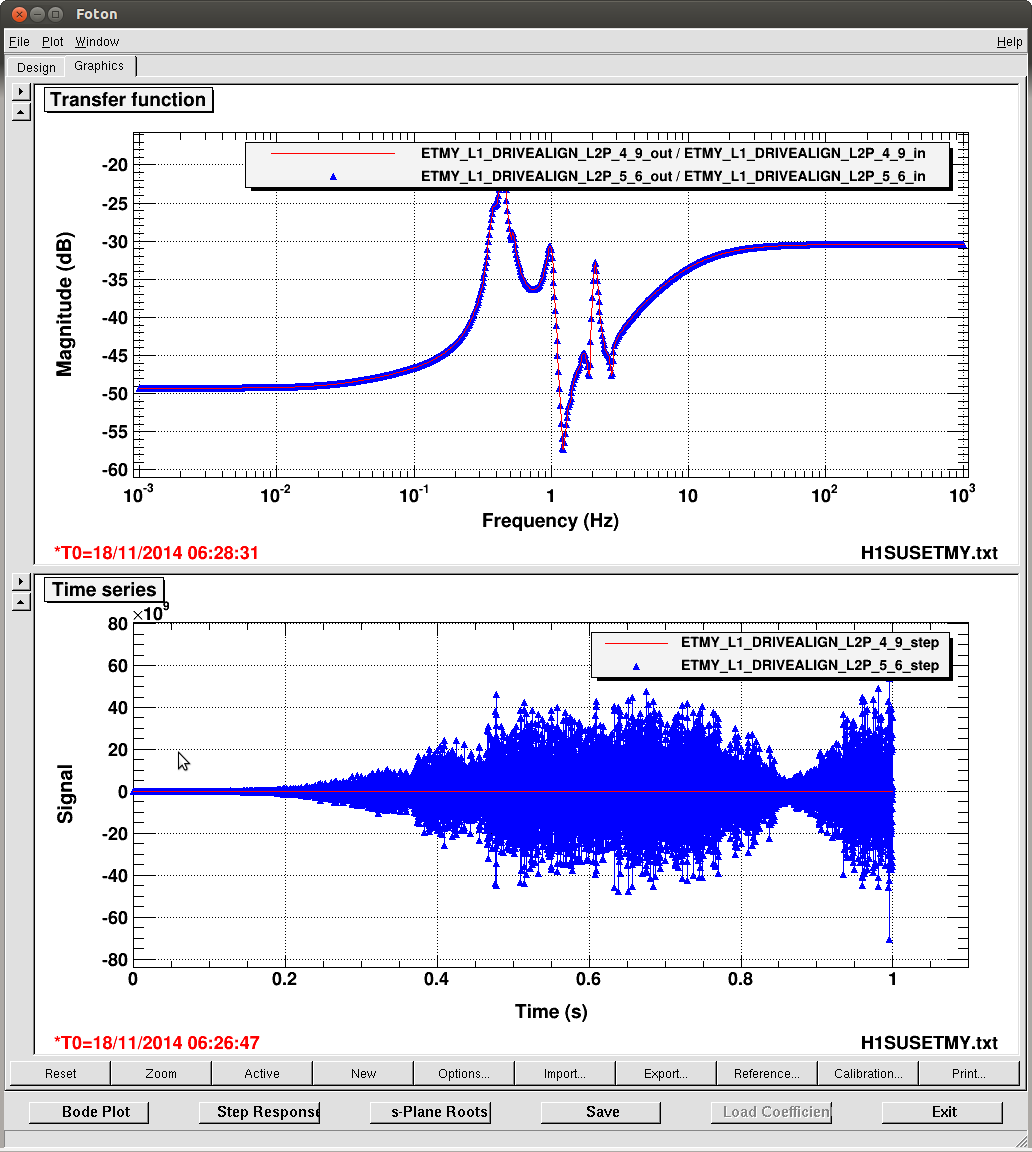

J. Kissel I've measured new transfer functions necessary redesign of the H1SUSETMY UIM (L1) DRIVEALIGN frequency-dependent decoupling filters for L2P and L2Y. For the impatient, the last page of the last attachement shows a comparison between the proposed new design and the old, currently installed / in-use design. I have *not* installed this filter because I'd like to discuss the results with commissioners tomorrow morning (and it'll take me some time to resurrect quack to get these installed). In fact, this may argue for us to indeed just copy over ETMX's filter. Details: ----------------------------------------- I attach the measurement results (see 2014-11-13_H1SUSETMY_L1_drivealignfilters_rawdata.pdf), but the raw templates can be found here: /ligo/svncommon/SusSVN/sus/trunk/QUAD/H1/ETMY/SAGL1/Results/Data/ 2014-11-13_H1SUSETMY_L1_L2PY_WhiteNoise_ReactionChainTest.xml 2014-11-13_H1SUSETMY_L1_L2PY_WhiteNoise.xml 2014-11-13_H1SUSETMY_L1_P2PY_WhiteNoise.xml 2014-11-13_H1SUSETMY_L1_Y2PY_WhiteNoise.xml Not that I drove through the TEST filter banks (instead of having to turn off all the existing filters in the LOCK and DRIVEALIGN banks), and made sure that optical lever damping was OFF, and local damping was the LLO design as described in LHO aLOG 14959. I focus this entry solely on L2P, but the data exists for an L2Y filter if ever needed. in the first four pages, Pink curves are the current measurement, and black curves are what were used in the original design of the previous filter by Arnaud (see LHO aLOG 11832). The encouraging fact is that the data supports exactly what we'd model from the change in damping loop filter design (see green traces on pg 5 of first attachement to LHO aLOG 14959). As an aside -- just because Betsy made me think of it while chasing down slider values -- what effect does reaction chain alignment have on these off-diagonal, lower-stage transfer functions? One might guess that if the L2P cross-coupling isn't something fundamental but a result of dirt alignment affects between the coils on the reaction chain and the magnets on the main, then one would see a change in the L2P transfer function with different alignments of the reaction chain. The good news is that is doesn't have any effect -- see the last page of 2014-11-13_H1SUSETMY_L1_drivealignfilters_rawdata.pdf. I compare the same transfer function for 4 different reaction chain alignments. They still have the old dead-reckoned calibration factors installed, so we know they're not exactly [urads] but close enough for the scale of these offsets used; they use up about 1/2 the DAC range. As far as the design goes, I used the same transfer function fitting routine and filter generation software suite that (I think) Arnaud used, namely the function /ligo/svncommon/SusSVN/sus/trunk/QUAD/Common/FilterDesign/Scripts/Length2Angle_decoupling.m which is essentially a wrapper around the function, /ligo/svncommon/SusSVN/sus/trunk/Common/MatlabTools/happyVectfit.m which Keita's wrapper around the function, /ligo/svncommon/SusSVN/sus/trunk/Common/MatlabTools/vectfit3.m All tweaking of input parameters to the fitting routine, and plots were made using the overarching script /ligo/svncommon/SusSVN/sus/trunk/QUAD/H1/ETMY/SAGL1/design_H1SUSETMY_L1_L2P_20141113.m Notable key additions to the design software -- a computation of the final filter's impulse response, as well as a comparison to the previous design. As I know Arnaud had struggled, I struggled to find a fit with which I was really happy, namely because we all *know* that the L2P transfer function should fall off as some large power of frequency (again, see the models of these TFs on pg 5 of LHO aLOG 14959), but I can't find a set of parameters happyVectFit / vectfit3.m that allows for such a roll-off at high frequency. Indeed, the height of the final flat part of the L2P fit transfer function directly determines the high-frequency gain of the decoupling filter, and directly impacts the impulse response time. I settled on a filter that does a poor job at reproducing the > 2 [Hz] behavior of the L2P measurement, BUT I think it's OK because (a) the small magnitude of the high-frequency causes a significant drop in impulse response time, and (b) At the UIM, we're typically driving below 2 [Hz] -- especially if the crossover remains at 0.9 [Hz] as quoted in LHO aLOG 15025, so the accuracy of inversion is not so critical. Though I didn't find any design aLOGs, this seems to have been the philosophy behind the ETMX UIM L2P filter because it ends up looking strikingly similar. I should say also that having to tune the uncertainty tolerance, the order (i.e. number of poles) in the filter, the tolerance for when to throw out adjacent poles and zeros, the frequency range over which to fit -- all free parameters into happyVectFit.m -- as one has to do to get what one wants in the end really destroys the advantage of automating the fitting process. If only there was a better way...

I've installed the filter into H1:SUS-ETMY_L1_DRIVEALIGN_L2P filter bank, in FMs 5&6 via autoquack.

HOWEVER

(1) I have not tested the filter performance with transfer functions or step response

(2) I've split the L2P and (invP2P * rolloff) into two filter banks. Even with the rolloff, the (invP2P * rolloff) filter has more zeros than poles, so foton has added a whole bunch of high-frequency poles to compensate. Though the *total* filter's -- L2P * (invP2P * rolloff) -- number of poles is equal to the number of zeros, I think the high-dynamic range, zero pole, cancellation between the two filters isn't working out. This is resulting in a HUGE calculated impulse response, which may or may not be real.

(3) This is my first time using quack to install Matlab filters into foton in a *really* long time, so I'm nervous of its functionality.

I attach a series of comparisons with ETMX's filter. The bode plot, in the frequency band we care about (pgs 1 and 2) seems reasonable. Both ETMX and ETMY have some high-frequency garbage in their impulse response, but the overall amplitude of the impulse response in ETMY is many orders of magnitude larger than that of ETMX (!!!). Further, taking the transfer function out well beyond the Nyquist frequency, we see that they behave significantly differently at the Nyquist frequency (~7 [kHz]).

As such, I'm still entirely unsure that this new filter gunna work, and may require further tweaking.

Anyways, these are installed in

FM5 "UIM_L2P"

FM6 "UIM_invP2P"

and should be turned on TOGETHER, with no other filters engaged in the module, if one would like to be bold and try it over the weekend.

P.S. in case you've forgotten, when you autoquack in a filter who's name has a space in it, and you try to load the new filter coefficients, Foton will hate you. You will, at least, get a nasty-gram on the GDS_TP screen's filter message, ${IFO}:FEC-${DCUID}_MSG saying "bad filter coeff definition on line 259 in .txt," pointing you to the exact line of the problem. So with Jim's confirmation that "Oh yeah, you DEFINITELY don't wanna do that." I changed spaces to underscores and all worked fine.

These filters did indeed run away and saturate the DAC. (The EPICS values were even showing “-Inf,” I’d never seen that before). I don’t think we can get away with more zeros than poles in a filter module, even if they are compensated by some other module.

I took the two filters (FM6 and 7) and viewed them in the foton “Multiple” mode, then I took the output in the “Alternate” box of foton and copied that into FM10.

When I tried this, instead of a huge mess I got a nice step response according to foton, and the frequency response was the same as the two original filters. As seen below (new is red, old is blue):

However, stupid foton wouldn’t save the filter (but gave no error message). In the end, I had to take this “Alternate” output and split it up into two filters, being careful that each had more poles than zeros. This allowed me to save the foton file and load the filters into the frontend. I tested that the impulse response behaved nicely by putting an offset into the filter bank.

The two filters are in FM5 and FM10. Their names reflect my frustration.

I silently started studying the performance of the HLTSs, i.e. PR3 and SR3. The major questions I want to answer in this study is:

I did not get a point where I can conclude something yet, but here are some summary of what I did today for it. To be continued.

(what I did)

To start off the study, I did measurements of the pitch transmission -- a transfer function from the suspension point to the mirror in pitch -- on PR3. Since SR3 did not have a GS13 witness sensor routed to the front end model yet, I was not able to get the same measurement on SR3 this time.

I shook ISO_RY_EXC of the HAM2 ISI in order to have better signal-to-noise ratio in the measurement. Note that a passive measurement without excitations did not give me good coherence and so for the reason I ended up shaking the ISI. I used random noise excitation in a frequency band of 10 Hz and limited the amplitude to be 200 counts in order not to trip the ISI watchdog. Also I have added 3rd order boosts below 1 Hz in the excitation in order to further improve the signal-to-noise ratio at the low frequencies. The dtt file currently resides in /ligo/home/kiwamu.izumi/Public/dtt/PR3_pitch_ISI_excitation.xml

I did the same measurement twice, one with the oplev damping loop running in pitch and the other without the oplev damping. The attached below shows the results. The red traces are the ones with the oplev running and the blue are without the oplev running. As seen, the oplev damping loop suppresses the components in 0.1-2 Hz at a cost of a gain peaking at 3 Hz. Since the rms is usually dominated by the components below 1 Hz, this confirms that the oplev damping loop is doing the right job.

(Next move)

As a next step, I would like to compare the pitch transmission with a model in order to see whethere it is something we expected or not.

I tried out a different version of the charge measurement. I'll detail it more later but the gist of it is that I drive the pitch of the TM using the built-in frontend lockin and feed back the lockin output to an offset on the ESD quadrant drive. This is done without any DC bias on the full face bias electrode.

In any case the effective offset voltage I measure for the four ESD quadrants are:

LR: 184V

LL: 159V

UR: 1V

UL: 12V

To understand the origin of the offsets I had to add ot almost all IMC ASC loops, I recentered the two IMC WFS, using the picomotors.

The offsets changed, but they didn't go to zero. So we can now conclude that the offsets are dependent on the WFS centering, as expected.

Then, I started moving around the beam on MC2_TRANS QPD, again using the picomotors. This alos had an effect on the intensity noise coupling. I removed all offsets from the loops, moved the beam on MC2_TRANS, trying to minimize intensity noise. This task was particularly difficult, for two main reasons. First, every time I moved the beam on MC2_TRANS, I had to recenter the beam on WFS_A and WFS_B. Second, HAM3 ISI tripped few times, messing up with my tests.

However, I believe I found a good position of the beams on the QPDs/WFSs. At present, there are no offsets in the loops, and the beam spot position on MC2_TRANS should be good enough to give us low intensity noise.

I checked the optimal offsets using the usual scatter plots, and it appears that things could still be improved with an offset in DOF_1_YAW, so the present position is not yet optimal. More tweaking tomorrow, but only in the case the present offsets remain stationary over night.

I also recenter IM4_TRANS_QPD.

Hugh, Evan, Kiwamu,

Since Keita established a new good SR3 alignment (alog 15020), we tried moving the oplev QPD to center the beam on it. However it turned out that the beam seems to be largely clipped on its way to hit the QPD. We could not identify what clips the beam.

We decided to steer SR3 back to the old angle such that we can reliably engage the oplev damping loop for tonight. This should be fixed tomorrow morning.

(some details)

When SR3 was on the new alignment values, the sum of the oplev signals was about 200 counts. We thought this was due to the beam mostly falling off from the QPD, but it turned out that the beam was actually still on the QPD but with the most of it clipped somewhere. We also made sure that we did not catch a ghost or some kind of fake beams by moving the QPD stage around. We steered SR3 back to the old angle and saw the sum going back to 30000 counts or so with pitch and yaw going back to 30 urad or so from 0 urad in the oplev screen. We are concluding that the oplev beam is clipped at some point between the SR3 optic and the QPD when SR3 is in the new angle. We need to open the receiver box and see what is going on. For tonight, we decided to set SR3 back to the old angle in order for us to be able to engage the oplev damping loop which was a key for stable SRC.

It seems that the cliiping-like behavior happens only when steering SR3 in the positive direction in pitch. This was confirmed by steering SR3 and monitoring how fast the sum drops as the beam starts falling off of the QPD. Aparently the positive direction in pitch makes the sum drop faster than the other three directions (negative pitch, positve and negative in yaw) and the other three directions showed almost the same speed of the decrease in the sum.

Bubba and I are making progress understanding the control logic (and illogic?) of our VEA control loops. We have turned on heaters in all three VEA/LVEA areas in order to compensate for the cold front.

Provided we have made sensible changes to the system we should see things stabilizing overnight.

One mechanical problem found was an outside air damper at Y END which was not able to close - therefore admitting a significant amount of cold outside air. We did not have a similar problem at X END where the excursion was much less pronounced.

Hopefully this mechanical fix and some parameter changes will settle things.

Dan, Fil

We've modified the QPD transimpedance board for the ASC-AS_C QPD so that the SUM output that's used for the fast shutter triggering no longer saturates when the DRMI is locked at 10W. We swapped R23 from a 20k ohm resistor to 1.24k ohm; this change reduces the amplification of the SUM output by 16x and brings the board (S1301506) into agreement with version 6 of the schematic (D1001974). [NB: with the DRMI locked at 10W we observed ~3.3mW on ASC-AS_C, or ~130mW into HAM6; this is dominated by the 45MHz sidebands and it roughly aligns with what's expected at 10W (65% transmission of 45MHz sidebands to the AS port, Gamma2=0.28 gives 112mW into HAM6 -- probably we are getting some extra light from higher order modes).]

We also modified the controller box for the HAM6 shutters to have the correct output polarity. The output from the box (S1203609) was previously +5V on a trigger condition (shutter CLOSED) and 0V on a nominal condition (shutter OPEN). We implemented the version 2 modifications to the board (D1102312), namely connecting pin1 of U8A (the OUTN signal) to the front-panel OUT connector, and connected P2 pin1 (the OUT signal, opposite polarity from OUTN) to the J1 pin10 slot on the D880C card. Note that we only modified channel1 in this box, we left channel2 as we found it.

Now, the SUM output from ASC-AS_C should not exceed 1V when the DRMI is locked (unless we mode hop?), and the controller output will be logic-low upon a trigger condition. The trigger output has been connected to the OMC PZT driver board, we'll commission the PZT shutter function soon. (Zach's results from L1 are here.)

I've verified that the trigger function works from the control room via the Beckhoff interface. The code for this function may need to be modified to accomodate the toaster shutter, which has its own Beckhoff interface and will record a fault condition if the input from the shutter controller is logic-low for too long. Currently the shutter controller will not reset the trigger logic without user intervention; it might be a good idea for the logic signal to reset itself after the PD input has passed below threshold, and have the fast shutter state remain closed (i.e., toast up) until a user/guardian/script opens it.

8:00ish Karen, Kris, Aaron in LVEA

9:00 JeffB, Andres to LVEA

9:15 Fil, Karen, Kris to EY

10:00 Betsy Travis to LVEA West Bay

10:45 Gerardo to H2 PSL enclosure

11:00 Fil to EY

13:30 Fil to CER

14:30 DanH to HAM6

15:00 Kiwamu to ISCT6

J. Kissel, A. Staley, K. Izumi, K. Kawabe Continuing investigations of why ETMY behaves poorly when attempting ALS DIFF (see LHO aLOG 15037) -- I've looked at two more things: (1) Pitch-only optical lever Damping: This had been turned on only *after* it had been decided that ETMY was "fragile," i.e. any impulses would shake the SUS quite a bit -- but I checked it anyways. First attachment is comparing spectra with the PUM (L2) stage actuated, optical lever Pitch damping loop ON vs. OFF. It's damping pitch, as expected, and not injecting anything terrible. This of course is assessing the stationary noise, and we're worried about non-stationary problems ... but ruling things OUT with quantitative data, I feel, is just as important along the investigatory route. (2) DRIVEALIGN Matrices: I attach comparisons between everything in the ETMs UIM (L1) DRIVEALIGN matrices (Only the P2P, Y2Y, and L2P have anything in them, so those are what's compared in the attachment). I believe the original design intent for P2P and Y2Y filters was to have global WFS transfer function be similar to the test-mass transfer functions -- hence the high-Q, plant inversion-y type stuff. They are slightly different between the two test masses, but, in-fact, they don't matter matter at all because we don't feed any angular signals to the UIM stage. However, I've found that the ETMY UIM L2P frequency-dependent decoupling filter in the UIM bank is significantly different than ETMX's -- and the filter has a much larger step response. I compare three different sets of filters on pgs 1 and 2: ETMX -- FM1 & FM2, "L2P" & "L2P2" ETMY, Current -- FM1, FM2, & FM4 "L2P", "L2P2", and "BetterRolloff" ETM, Legacy -- FM6 & FM7, "L2Plegacy" & "L2P2legacy" It looks like the initial story here is laid out in LHO aLOG 11832, but there're several more aLOGs referencing UIM / L1 L2P Filters, and how they've been bad, they've been good, they've been turned off, they've been turned on... The foton calculation of the step response disagrees with the measured step response LHO aLOG 14832 -- but recall that the filter step response is not the only thing measured in that 14832 measurement -- it's measuring both the filter AND mechanical step response. We now have local damping filters from LLO which has reduced the mechanical impulse response time by a factor of a few. This, coupled with a smaller impulse response filter should help, but we'll remeasure once a new filter is designed. I'll move on to chasing this down -- re-measure the step response, and also remeasure the plant upon which these filters were designed. Of course, an immediate, band-aid fix could be just to copy ETMX's L2P filter over to ETMY, but while we wait for the temperature in the VEAs to settle down, I've been given the green light to measure some TFs.

CORRECTION:

The first attached plot in alog 14832 shows the impulse reponse of ETMY L1 stage with:

The trace the was *not* plotted was the ETMY, Legacy -- FM6, FM7. We had taken an impulse response of this configuration, but it was so bad that we did not leave it in the plot. Clearly this disagreed with Jeff's response.

The two attached images show the corner and end station topologies of the EtherCAT network, respectively.

The number of EtherCAT modules/terminals is 332 and 109 for the corner and end station, respectively. The total is 550.

Looking at the SR2 peanuts-shaped baffle, I set the new SR3 alignment offset.

SR3 Old: [430.3, 142.6]

SR3 New: [654.3, -38.8]

The original position was not that bad, it was a bit too the left and low.

After this, I scanned SR2 while centering the AS_C QPD using picos.

SR2 Old: [2963.7, 2728.0]

SR2 New: [1339.7, 1575]

The new AS beam position on the camera is to the left and high.

SR3 details:

Peanuts-shaped SR3 baffle was used as a reference.

The IFO beam is supposed to be in the right hole, the angle between SR3-SR2 beam and SR2-SRM is 29 mrad, the distance from the baffle to SR2 is about 460mm (just by eyeballing the drawing), so the beam separation on the baffle is about 17.5mm.

This means that the SR3-SR2 beam should be about 17.5/2 mm to the left from the center of the right baffle hole.

PR3 YAW offset when the beam just hits the right edge of the baffle was -1394.4, while the offset when the beam was on the center line of the right baffle hole was -194.4.

When looked from HAM5, the right baffle hole looks like an ellipse with the major axis vertical, and the minor radius is 67.5mm.

Therefore the PR3 YAW offset should be

SR3 Y = -194.4 + (-194.4+1394.4) * 17.5mm/2 / 67.5mm = -38.8

PR3 P offset when the beam hits the top/bottom edge of the tallest part of the hole was 2350.3/-1041.7, and the average is 654.3.

This also means that the SR3 YAW slider calibration is off.

For YAW, 1200 urad of the slider offset produced about 67.5mm.

2*angle*16m = 67.5mm -> angle = 2.1mrad.

Therefore, in reality, the SR3 slider calibration for Y is 2.1mrad/1.2mrad = 1.76. (But I'd claim that the measurement error is probably as large as 30% or so).

For SR3 PIT, it's good.

The beam moved from the bottom to the top with -3392 urad slider step. The hole height is 114mm.

2*angle*16m=114mm -> angle = 3.6mrad.

The SR3 slider calibration for P is 3600/3392 = 1.06

SR2 details:

Before SR3 bias was set, AS_C was centered using pico.

After SR3 was done, AS_C was centered using SR2 bias. After this, SR2 bias was [1399.7, 1485.0]. This is our "initial position".

Then SR2 bias was scanned first in Y, then in P, and then Y again.

Attached left is the Y scan and the right is the P scan. Blue vertical lines indicate where I started.

As I was sort of suspecting, PIT was more off than YAW, and anyway I settled on [P,Y]=[1339.7, 1575].

One caveat is that the final position corresponds to one data point where I see a jump in the AS_C SUM (look at the green circle that goes to 1.04). This is repeatable, and I think this is where some stray beam or maybe the reflection from the AS_C goes into the AS_C. I don't think this corresponds to smaller loss. This position was chosen as the final position by eyeballing the peak of the green plot excluding that abnormal data point.

Jason, Sheila

There have been some glitches on the ETMX oplev, which don't seem to correspond to motion of the optic, the attached screen shot shows an example. I think that I have seen glitches like this that were much larger in amplitude, but am not sure.

One question for detchar is if they have a tool that can search for glitches like these, and give us some information about how often they are happening, how large they are, and maybe monitor to see if they are happening on other op levs.

Another issue is that sometimes the lasers fail, which is often foretold by a several seconds oscillation in the oplev sum. Can detchar set up some kind of monitoring for that?

Of course the real question is how can we fix it......

Hi Jason and Sheila, here at LLO Olmo Cerri, a summer student from UMISS, looked at the possible causes of glitches in OPLEVs. He worked with Suresh. Suresh earlier found that the the temperature variation could cause changes in the cavities of OPLEV laser and thereby changing the laser intensity which would look like glitches. Olmo looked at week long strecthes of data from a few OPELVs and charactersized how many glicthes we see (he wrote a matlab script to find the such gltiches). They also implemetned a simple temperature stabilization method (LLO a-log) to reduce the gltiches. It seemed to work well. Here is a presentation by Olmo on this work which shows data before and after the temperature stabilization setup. He is now looking into implemneting an online version of the code.

I set Olmo's code to run on a cron job with the results here: https://ldas-jobs.ligo-wa.caltech.edu/~codyca/MHoF_results/ We still need to put together a better way to present the results. The code is set to remove glitches caused by human interaction by looking at the OPTICALIGN offsets. Also, the results for LLO can be found here: https://ldas-jobs.ligo-la.caltech.edu/~codyca/MHoF_results/

Probably it was me shaking the HAM2 ISI for checking the PR3 performance. Good catch !