(Alexa, Evan, Sheila, Nic, Kiwamu)

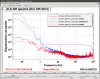

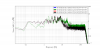

Tonight we locked ALS DIFF with a UGF of 8 Hz, phase margin of 60 deg (2014-11-12-ALS_OLTF.pdf). The in loop noise is 1e-3 um/rtHz RMS down to 0.1 Hz (ALS_Diff_spectra_11122014.pdf). This is comparable to our old ALS_DIFF spectra, which was comparable to HIFOXY days.

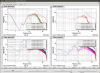

We are running under a similar configuration to LLO. We are using an offloaded distribution for the Quads. Our LSC-DARM and L1_LOCK_L filters are similar to LLO's as described in alog 14961. We have added a resG filter in LSC-DARM to supress noise at 1 Hz and 0.4 Hz. We also added an additional boost in the L1 LOCK L stage to improve our RMS at low frequency. The ESD LOCK L filter was initially empy; however, we added an elliptic filter in L3_LOCK_L to supress noise we saw at around 100 Hz in the ESD coil output, and to reduce the range we use on the ESD coils. The current LSC-DARM filter is shown in LSCDARM_filters.pdf. Meanwhile the L1_LOCK_L filter with the addition of the ESD ellpitcal filter is shown in UIM_filters.pdf.

We have about a factor of 7 headroom in the ESD before we would saturate, and about a factor of 30 head room in the ESD. Tonight the 1-3 Hz seismic is fairly high (0.1 um/sec) but the low frequency is low (0.2 um/sec at 0.1-0.3 Hz). So it seems like we have some room for the seismic to get worse without needing to add the top mass.

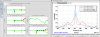

Our UIM/ESD crossover is at 0.9 Hz with 50 deg phase margin. The L1_LOCK_L_GAIN = 0.28, L3_LOCK_L_GAIN = 1. We collected data from L1_LOCK_L IN1/IN2 to measure the crossover (UIM_measure_EXonly.pdf). The data is also depicted in DARM_crossovers.pdf; this image also shows the same TF produced by the model along with the UIM/ESD. The model seems to agree with the data well; albeit with a gain of 5 fudge factor. I have also attached the OLTF produced by the model (DARM_TFs.pdf).

We found we could stabily and repeatbly lock ALS DIFF with a LSC-DARM gain of 400. We were ONLY feeding back to EX. We are suspicious of the EY ESD; when we feed back to EY the y-arm eventually drops lock even with a low DARM gain. We did little investigation into this issue.

ALS_DIFF guardian has been updated, and can lock DIFF in this configuration.