J. Kissel

The Message: I've cross-checked the calibration of all the ground sensors at the X End-Station, and used that knowledge to gain further confidence in their assessment of ground motion and ground tilt (second attachment). With these confirmed sensors, I tried to figure out why no one can find coherence between the ISI T240 X and either the GND BRS RY or GND T240 X (first attachment). My conclusion is that the ISI ST1 X DOF is limited by re-injected noise from ISI ST1 RY DOF between 20 and 200 [mHz], because we've copied and pasted our X T240 blend filter to RY without being conscious of this tilt-horizontal-coupling path (fourth attachment). I *think* this noise, is T240 sensor noise in this 20 to 200 [mHz] frequency band (see fifth attachment). This can be solved by sacrificing unneeded higher-frequency performance in RY (say between 1-10 [Hz]), and moving the RY blend up a bit, and making the T240 high-pass roll-off more aggressive, or "faster," as a function of frequency (third attachment is current X / RY blends).

%%%%%%%%

% The Deets %

%%%%%%%%

Calibration:

------------

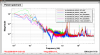

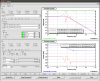

In the second attachment, 2014-09-18_H1EXGND.pdf, I've calibrated everything into translational acceleration units. I summarize here, then explain the details after.

Summary:

(1) H1:ISI-GND_STS_ETMX_X_DQ 1e-9 [(m/s) / ct] --> Let DTT differentiate once to acceleration units

(2) H1:ISI-ETMX_ST1_BLND_X_T240_CUR_IN1_DQ 1e-9 [(m/s) / ct] --> Let DTT differentiate once to acceleration units

(3) H1:ISI-GND_BRS_ETMX_RY_OUT_DQ 1.568e-8 [(m/s^{2}) / ct]

(4) H1:PEM-EX_SEIS_VEA_FLOOR_X_DQ 7.9e-9 [(m/s) / ct] --> Let DTT differentiate once to acceleration units

(5) H1:PEM-EX_TILT_VEA_FLOOR_X_DQ 5.5e-8 [(m/s^{2}) / ct]

(6) H1:PEM-EX_TILT_VEA_FLOOR_T_DQ 5.39e-7 [(m/s^{2}) / ct]

For (1) and (2), myself and the SEI group have graciously calibrated these channels into 1 [(nm/s) / ct] in the front end, following the electronics chain as described in D1001575. So I merely have to convert to (m/s), and let DTT handle the differentiation by requesting m/s^{2} / Hz^{1/2} on the units menu.

For (3), Krishna and I have installed a similarly dead-reckoned calibration that we believe is in 1 [nrad/ct]. However, converting to translational acceleration by multiplying by g = 9.8 [m/s^{2}/rad] and by 1e-9 [m/nm], leaves a discrepant factor of 1.6 between the GND T240 and the GND BRS (see pg 1 of

2014-09-18_H1EXGND.pdf), where there is great coherence, between 10 and 100 [mHz] and we expect the signals to be the same. Also notice the how the harmonics is the 8 [mHz] resonance pollute the spectrum (the BRS has been rung up to +/- 200 [ct] during this measurement period). That's when I invoked the PEM sensors, hoping they would be coherent enough between the sensors to cross-check, but alas, in the 10 to 100 [mHz] region, they're too noisy to really tell if the GND BRS or GND T240 are "right," so I added in the extra factor of 1.6 assuming the T240s were correct, hence 1.6 * 9.8 * 1e-9 = 1.568e-8 [(m/s^{2}) / ct]

For (4), I used the pem.ligo.org prescribed 7.6e-9 [(m/s) / ct], it matched the GND T240 very well (within the 22% quoted precision) in the frequency region where we expect them both to be sensitive to translation, i.e. above 100 [mHz].

For (5) and (6), since the instrument has not yet been successfully calibrated (see LHO aLOG 13623) I assumed the that GND T240 and GND PEM Guralp were correct, and simply scaled the PEM TILT X channel to match them above 100 [mHz], ending up with 5.5e-8 [(m/s) / ct] (and let DTT do the differentiation). I then blindly assumed that the Tilt channel uses the same calibration value, but for rotational displacement, i.e. 5.5e-8 [rad/ct]. Scaling by g = 9.8 [m/s^{2} / rad] that yeilds the above 5.39e-7 [(m/s^{2}) / ct]. It seems to match up reasonably well, and it's not hard to imagine that the electronics chain is the same for both channels, but the sensor appears to be limited by some noise incoherent with the GND BRS in the 10 to 100 [mHz] region.

The Tilt-Horizontal Coupling Model:

-----------------------------------

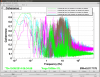

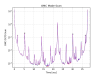

On the final page of 2014-09-18_H1EXGND.pdf, I plotted the ISI performance against all of the ground sensors, and noted the hump between 10 and 100 [Hz] that looked suspiciously like a blend filter bump. Going on a hunch I've had for a while Similar to what I did in my thesis, knowing that we've thus far only copied and pasted our X blend filters to the RY DOF, I used the same 1-stage, MISO model (e.q. 5.3 on pg 80) to predict how much the residual platform tilt (RY) motion is coupling into the X DOF,

G_x g x

x = ------- * ----- * F * res RY

from res RY 1 + G_x w^2 T240 HP

Thankfully, at these low frequencies (f < 1 [Hz]), the ISIs have loop gain, G_x, much much greater than 1, the closed loop gain (the first term) is well-approximated by unity, and I only have to know the blend filter F^{X}_{T240 HP}.

This model shows varying degrees of success.

(1) Between 50 and 300 [mHz], this predicts the X ST1 motion exactly. ISI T240 RY doesn't show coherence, however, but I'm confident that's because it's incoherent sensor noise of the RY loop in this band -- at least up until 100 [mHz]. I'm still confused why the double-peaked microseism (100-200 [mHz]) in ISI X is very coherent with GND X, but (a) doesn't show up in nor is it coherent with the GND RY spectrum, and (b) perfectly matches the shape of the ISI RY motion projected into ISI X.

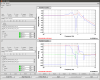

(2) The model WAY over predicts the X displacement between 10 and 60 [mHz]. I've triple-checked my blend-filter-multiplication-via-DTT-calibration, and I'm confident I'm doing it right -- see third attachment. Steps:

- Grab a matlab version of the blend filter from ${SeiSVN}/seismic/BSC-ISI/Common/Complementary_Filters_BSC-ISI/aLIGO/TSheila.mat

- Ask matlab for its poles and zeros via [Z,P,K]=zpkdata(High_Pass_Filters(1)), where X is the first DOF

- Turn them from [rad/s] into [Hz], by dividing by -2*pi

- Copy them into foton, bode plot, and find the correct normalization factor such that the filter asymptotes to 1 at high-frequency (-160.202 [dB])

- Copy the normalization gain, poles and zeros into DTT and multiply the correct displacement calibration,

gain: 1/(2*pi) [rad / (rad/s)] * 1e-9 [rad/nrad] * 9.8 [(m/s^2) / rad] * 1 / (2*pi)^2 [m / (m/s^2)]

poles: 0, 0, 0

zeros: [none]

(3) Independent of the model's confusion, at least it shows lots of room for improvement with GND X to ISI X in this region (100 - 700 [mHz]).