We reported last week that the pitch RMS motions of the bottom masses was dominated by 0.5 Hz features on all BSC units. We are looking at the coherence between ISI, Suspension top mass and optical levers to find out how to reduce the bottom masses angular motion.

Plots:

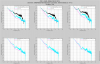

The first figure attached shows coherence plots, the second figure shows transfer functions plots:

- in the top left, from "ISI longitudinal" to "SUS top mass longitudinal"

- in the top right, from "ISI longitudinal" to "SUS top mass pitch"

- in the bottom left, from "SUS top mass longitudinal" to "Optical Lever pitch"

- in the bottom right, from "SUS top mass pitch" to "Optical lever pitch"

Comments:

At 0.5 Hz,

- the coherence between ISI longitudinal and SUS top mass motion is not very high. We'll add more ISI channels to see how they contribute to the suspension point motion.

- the coherence betwen the suspension top mass and the optical levers is above 0.9 (above .99 in some instances). The BS longitudinal to pitch transfer functions show a Q around 20. The pitch to pitch transfer functions show similar Qs for all units. We can compare this to damping models.

Corrections:

- I used one hour of data starting on Monday Oct 27, 3 am PT.

- I fixed the axis labels and plots titles