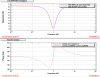

We just turned off the CO2 laser. We had seen our contrast improve from 99.1% to 99.8% (after about 7 hours at 192 mW CO2 power), and finally after about 19 hours we measured the contrast at 99.6%. Dan has also measured the OMC mode matching, which seems to have gotten worse for ITMX (measured around 17 hours). In the few minutes since we turned it off, the contrast has improved again.

Today we have had considerable difficulty locking DRMI, beause of the mode hopping problems. There are many examples of short locks where the mode hopping seems to have killed the lock, some times are (all UTC, october 16th) 23:50, 23:23:50, 22:48, 22:26:27, 22:10, 20:44:20, 20:41:30, 20:36:04 and 20:34.....

Our difficulty today may or may not have been related to the TCS, it may just have been that our alingment was bad. We did have 2 longer locks, each about 20 minutes.

We decided to try locking PRMI, to see if we could get a better handle on alignment. I edited the PRMI guardian (in LSC configs) so now it is using the refl air PDs, and the gains are correct now that we are using the power scaling. (110 for MICH, 22 for PRCL) The distressing news is that now PRMI has a similar mode hopping behavoir to what we see in DRMI.

The first attached screen shot shows the way that our as camera has looked when mich was on a dark fringe most of the day today. The second one shows it about 7 minutes after we turned the laser off.