This morning I put in upgrades for both guardian core (r1076) and cdsutils (r322). All guardian nodes have been restarted (except for ITMX SUS and SEI which are under test by Jim W. Will restart as soon as he's done).

cdsutils r322 new improvements/features:

- add "gpstime" module for handling GPS times

- fixes/improvements to "audio" command (i.e. "rockifo")

- new "water" command for waterfall plotting

- new "step" command, and guardian-friendly Step class

- minor performance improvements to Ezca and LIGOFilter

- improve test suite

- improved documentation

guardian r1076 improvements/features (see also LLO aLOG 13930):

- support user-assigned state indices

- add node NOMINAL state, which represent the intended state during full operation

- add node OK status bit, which is True if the node is running, in it's NOMINAL state, not in error, etc.

- improved test suite

- improved documentation

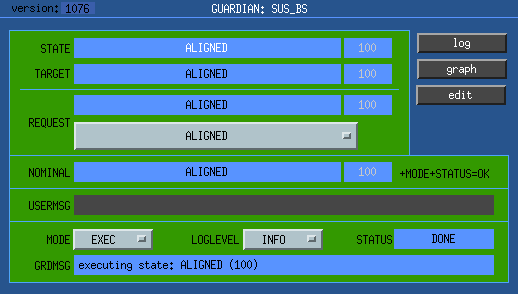

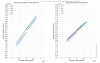

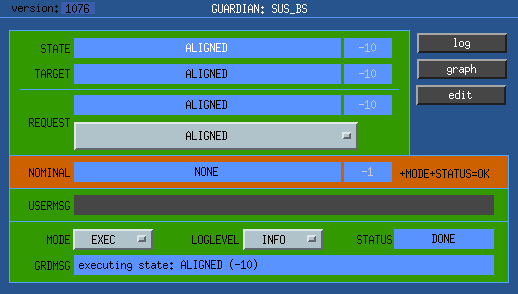

Here's the updated guardian control screen that comes with this upgrade:

Note the new "NOMINAL" state field. The NOMINAL state is NONE by default if not set in the code module (which is the case here for SUS_BS). The orange background reflects the fact that the new OK bit is False, which in this case is because there is no NOMINAL state set.

Also note the number fields to the right of the state names, which show the numeric index for the current states. Now that we manually set these numbers, they have a bit more meaning, which is why it's useful to display them.

We now need to go through all systems and add appropriate state indices and nominal state definitions. This was done already at LLO, so I'll be adopting the same standards.

ITMX SUS and SEI nodes have now been restarted, although the SEI is currently tripped as Jim W. is still working on tuning their loops.