Jeff K., Krishna V.

The tilt transfer function measurements were yielding inconsistent results and ultimately I decided that the error bars on the measurement are much larger than previously anticipated. The main reason is that I dont have a simple way of producing pure tilt on the platform, therefore cross-couplings are preventing few percent level accuracy on the transfer function measurement needed to measure d to better than ~ +/- 5 microns. Based on the GRND_T240 comparison, and the average of the transfer function measurements, we have reason to believe that the displacement rejection is better than 1E-4, which I decided was sufficient for now. Once plugged in to the LIGO DAQ, there may be other ways of estimating "d".

In the afternoon, I added multiple layers of aluminum foil and foam insulation to the vacuum can and the autocollimator. I then tried to turn the Ion pump on. To describe the problem, let me briefly summarize the pumping arrangement: Vacuum can --> Valve 1 --> Ion pump --> Valve 2 --> Temporary pumping station (Turbo).

The pressure at the Turbo was about 5E-7 torr.

The Ion pump turned on just fine and the current dropped down to <0.1 mA in minutes. I then closed Valve 2. The current went up to ~ 3 mA and then started going back down. SO far so good. I then turned the Turbo off and the current started rising! Valve 2 was leaking through flanges (not to outside), which was a surprise. I tested it again and same result.

Luckily, I was able to find a replacement valve very easily at the corner station. I closed Valve 1 and replaced Valve 2. I then pumped overnight with the Turbo.

On Saturday morning, I turned on the Ion pump and closed Valve 2. This time the current went up to 3 mA but then went down normally and did not rise when the Turbo was turned off. Whew! The current after an hour of pumping was 0.5 mA.

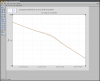

Overnight, I also took a ringdown Q measurement for the balance beam. The first plot shows the ringdown over 40k seconds. A second plot shows a zoomed in view. The log(Amplitude) is mostly flat but tends to get better at late times which was probably just due to the improving pressure. A straight line fit to the log(Amp) gives a Q of ~4800 and since the resonance frequency is 8.8 mHz, this gives a damping/decay time of 173k seconds or ~ 2 days!

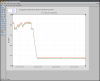

See the NPRO temperature (left bottom) and the PSL room table temperature (right top).