Sheila, Kiwamu (a report from yesterday)

We switched the approach for assessing the IMC loss from the ring down measurement (alog 13319, alog 13280) to a cavity pole measurement.

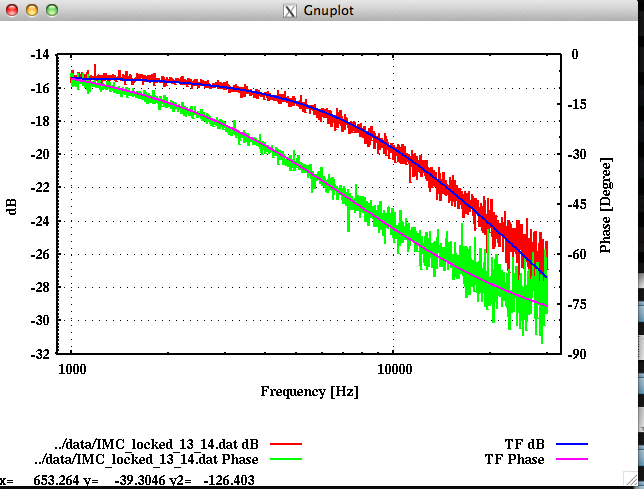

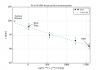

The estimated cavity pole is 7745 Hz while the previous measurement was 8850 Hz which was done in February in 2013 (alog 5429).

Note that an expected value from the mirror transmissivity measurements (see the galaxy web) without taking losses into account is 9011 8625 Hz (Thanks Dan !).

(The setup)

We tried reproducing the same setup as the previous measurement (alog 5429). We used a PDA55 for monitoring the injected intensity modulation on the PSL. This is the one under the periscope i.e. H1:PSL-PERISCOPE_A_DC. Then we hooked up an SR785 to this PD and the IMC trans PD (H1:IMC-TRANS) which is an PDA100A on IOT2L. We drove the AOM with an amplitude of 200 mV and frequency band from 1 kHz to 100 kHz, swept sine. We did two kinds of measurement -- first, we measured the IMC cavity pole by driving the AOM and taking transfer function from the PSL periscope PD to the IMC-TRANS PD. Secondly, we measured the PD responses by taking the transfer function of the same PD, but without any IMC interference by misaligning MC2. Note that in order to perform the second measurement we moved the position of the PD to the IMC-REFL path such that it can observe the direct reflection from MC1. Again, these procedure are the same as the previous measurement.

(The result)

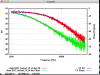

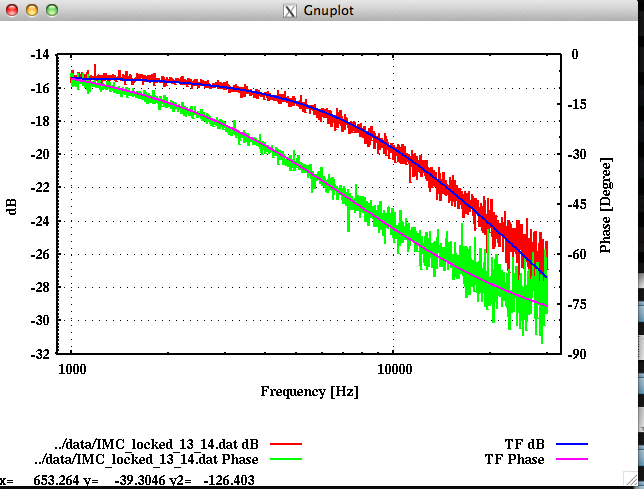

After taking the two transfer functions, we divided the IMC cavity pole transfer function by the PD response transfer function in order to reduce the effect of the PD responses. The below is the resultant transfer function and its fitting result.

I used the same fitting algorythm as Giacomo used (see alog 5541). The fitted cavity pole is at 7745 Hz. Since the data was noisy and showed a funny bump avobe 30 kHz, we excluded the data above it. Also, if we do not correct the PD response, the cavity pole is at 8380 Hz.