J. Kissel

The Messages:

(1) The effective bias voltage charge on the test mass is -28 [V_pk], which quite small compared to the BIAS range of 400 [V_pk] (and in conflict with Keita's assessment from the optical levers [see LHO aLOG 11905]).

(3) The force actuation strength is asymmetric with respect to bias voltage, confirming Keita's result (see LHO aLOG 11872)

(2) The force coefficient at 11 [Hz], measured as a function of bias voltage, is roughly 0.5e-10 [N/V^2], a factor of 8 below the expected 4.2e-10 [N/V^2] (expected from pg 7 of G0900956)

DETAILS

-------------

Brett: please proof read:

-------------

Note, no linearization algorithm was used during this experiment.

(1) Using the time-honored MIT method of measuring test-mass charge (e.g. from Brett, John, and Lisa), I drove a single frequency line into the control voltage H1 SUS ETMX ESD drive, looking at the X arm cavity length (as measured by green), while stepping the bias voltage through its entire range. As one steps down the bias voltage, we expect the linear response to drop to zero. Further, one can take the slope of the response as the bias decreases from both the positive and negative side and predict an effective bias voltage created by residual charge on the test mass. I attach the results. Using a linear regression, weighted by the coherence as follows,

unc = sqrt( (1 - coh) / 2*nAvgs*coh )

weight = 1 / unc^2;

I calculated the intersection of the two slopes to be -27.99 [V_pk].

I took an excessive amount of data points, because I didn't know what I was doing when I started and wasn't sure how the results would turn out. The template is here for excitation:

/ligo/svncommon/SusSVN/sus/trunk/QUAD/H1/ETMX/SAGL3/Data/2014-05-15_H1SUSETMX_L3_ChargeTest.xml

For the record, I tried using the script recommended by Brett (LHO aLOG 11914), but after updating all the necessary channel names and input variables. it failed deep with in its subfunctions because of some xmlconv library that's now gone missing since 2009. I didn't have the time nor expertise to debug, so I just changed the bias by hand and measured the ten averages with the GUI DTT session, capturing references as I went, and exported at the end for processing.

(2) No further details here, it's obvious that the drive strength is weaker with positive bias voltage than with negative. I have no good explanation for this.

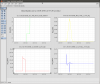

(3) From these displacement response results, one can also obtain the force coefficient for each bias step. The calculation is as follows:

disp_mpk = 1e-12 * sqrt(2) * sqrt(binWidth) * disp_pmrtHz;

force_Npk = disp_mpk * 1./compliance_11Hz.mpN;

V_CTRL.Vpk = nActs * sqrt(2) * sqrt(binWidth) * esdGain * excChannel.amplitude.V_DAC.VrtHz;

V_BIAS.Vpk = bias.V_ESD;

forceCoefficient = abs(force_Npk ./ (2*V_CTRL.Vpk * V_BIAS.Vpk));

where

disp_pmrtHz = displacement response of the arm cavity length at 11 [Hz] during each bias voltage setting, in [um] (which I subsequently turned into [pm] for plotting clarity) as measured from the calibrated ALS control signal, H1:ALS-X_REFL_CTRL_OUT_DQ

sqrt(2)*sqrt(binWidth) = sqrt(2)*sqrt(0.09375 [Hz]), calculation needed to change from noise units ?_{rms}/rtHz to amplitude units of ?_pk

1e-12 = 1e-12 [m/pm]

compliance_11Hz.mpN = 5.3e-06 [m/N], TST to TST, L to L transfer function at 11 [Hz], obtained from the QUAD model.

excChannel.amplitude.V_DAC.VrtHz = 12.45 [V/rtHz], measured output request voltage from the DAC (calibrated from counts out of the digital last output to ESD, i.e. H1:SUS-ETMX_L3_MASTER_OUT_LL_DQ using the 180bit DAC gain, 20/2^18 [V/ct])

esdGain = 40 [V/V], gain of the ESD driver

sqrt(2)*sqrt(binWidth) = sqrt(2)*sqrt(0.09375 [Hz]), calculation needed to change from noise units ?_{rms}/rtHz to amplitude units of ?_pk

nActs = 4, since the calibrated output requested voltage is only from one channel.

and I've computed the force coefficient, a, using only the linear term, since I used the amplitude of the linear term alone

F = a (V_CTRL sin(wt) - V_BIAS)^2

= a V_CTRL^2 sin^2(wt) - 2 a V_CTRL V_BIAS sin(wt) + a V_BIAS^2

[ sin^2(wt) = 1/2 - 1/2 cos(2wt) + O(4w) ]

= a(V_BIAS^2 + 1/2 V_CTRL^2) - 2 a V_CTRL V_BIAS sin(wt) + - 1/2 a V_CTRL^2 cos(2wt)

DC Term Linear Term Bi-linear Term

=>> Linear Term,

a = F (2 V_CTRL V_BIAS)

Confusingly, this resulting coefficient, a = 0.5e-10 [N/V^2] is a factor of 8 weaker than expected, which is *different* than the factor of 4 weaker that was needed to explain the linear transfer functions taken last week (see the second attachment of LHO aLOG 11676).

The script that processes the measurements is here:

/ligo/svncommon/SusSVN/sus/trunk/QUAD/H1/ETMX/SAGL3/Scripts/analyzeesdcharge_20140515.m