Kiwamu, Jamie, Lisa

We figured out why we couldn't reduce the CARM offset below 1kHz while keeping the PRMI locked on REFL 45 I&Q.

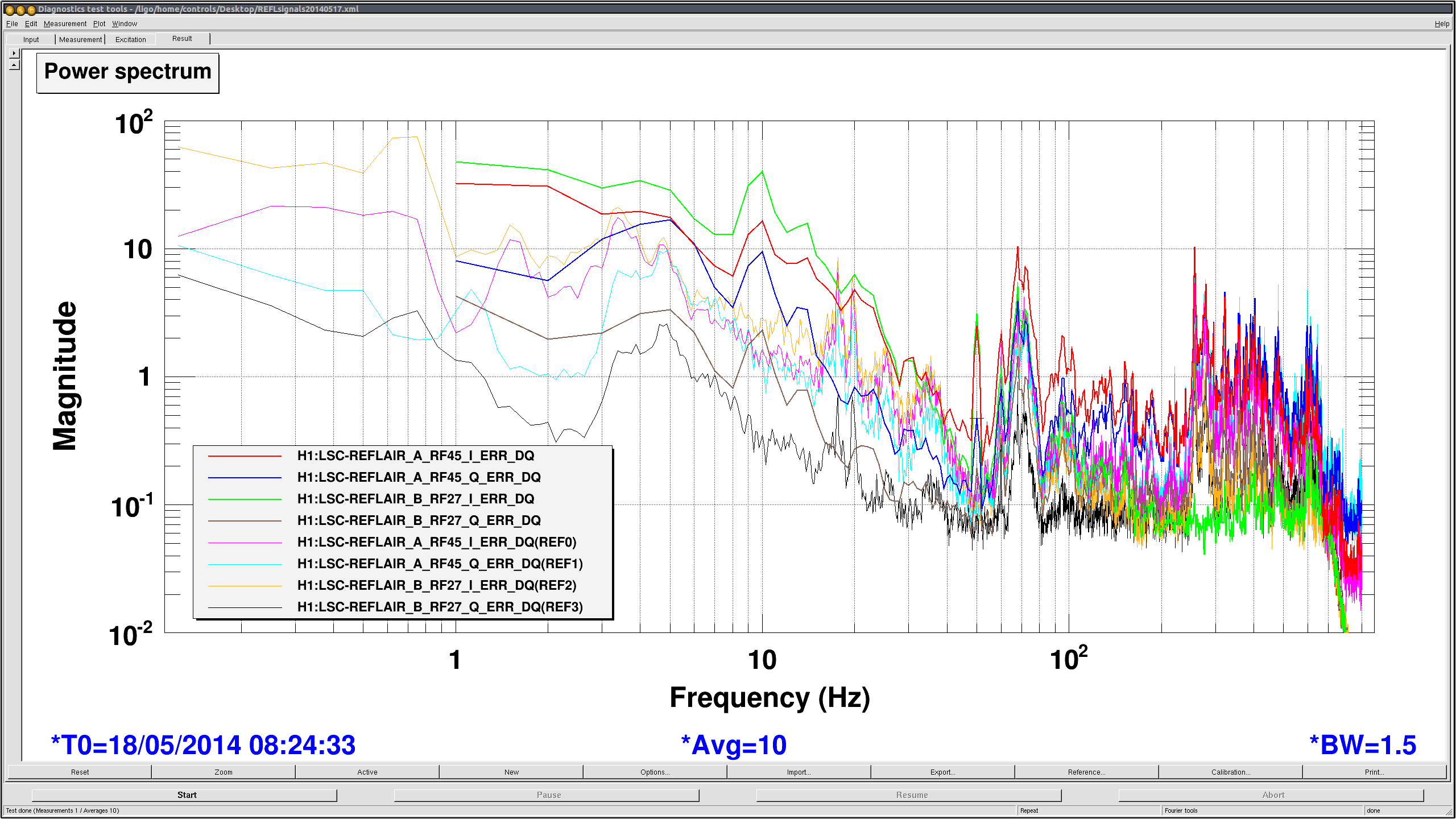

The REFL 45 demod phase was tuned without the arms present; it turns out that with the arms, even with a large CARM offset (1 kHz), the demod phase changes enough to make MICH very close to instability.

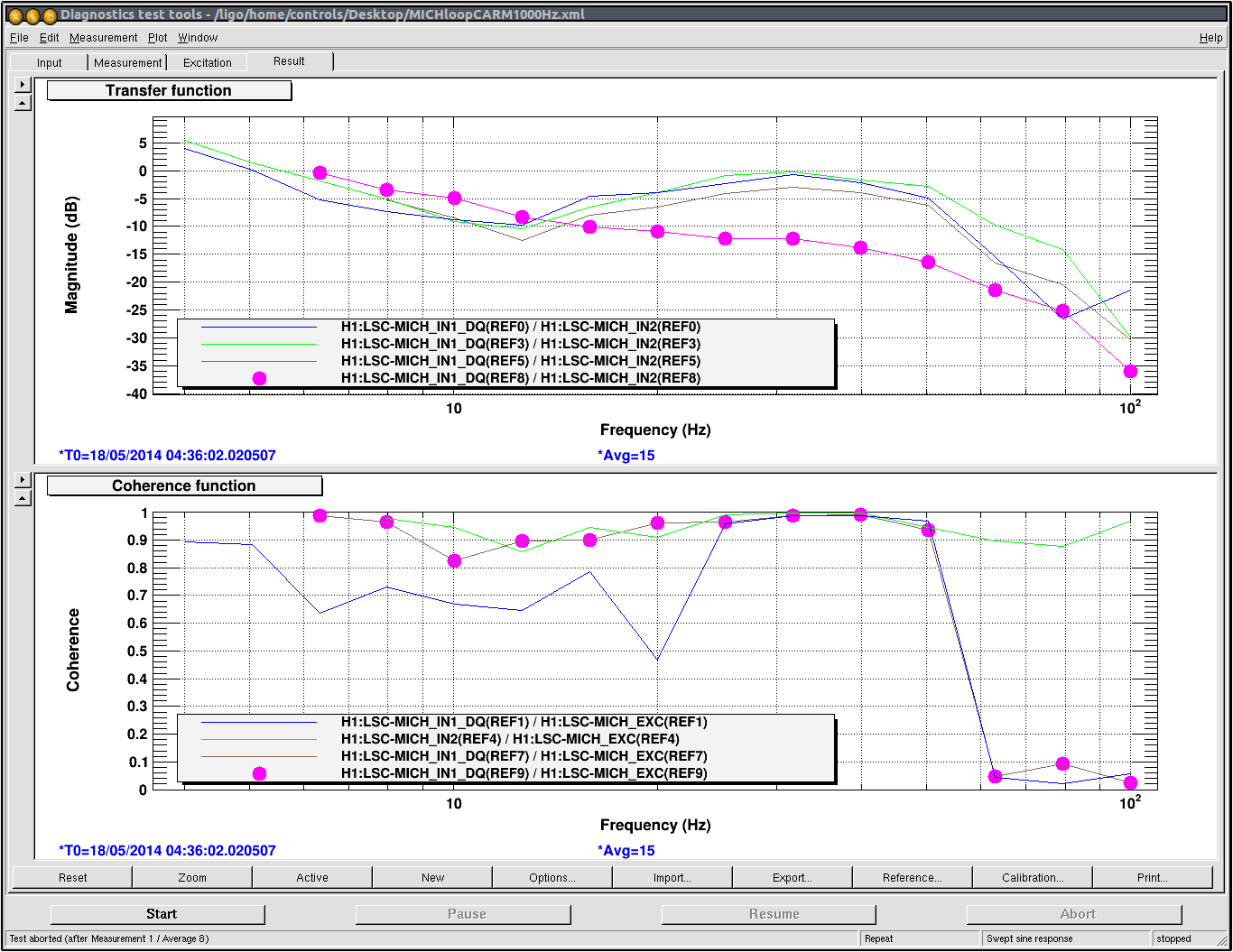

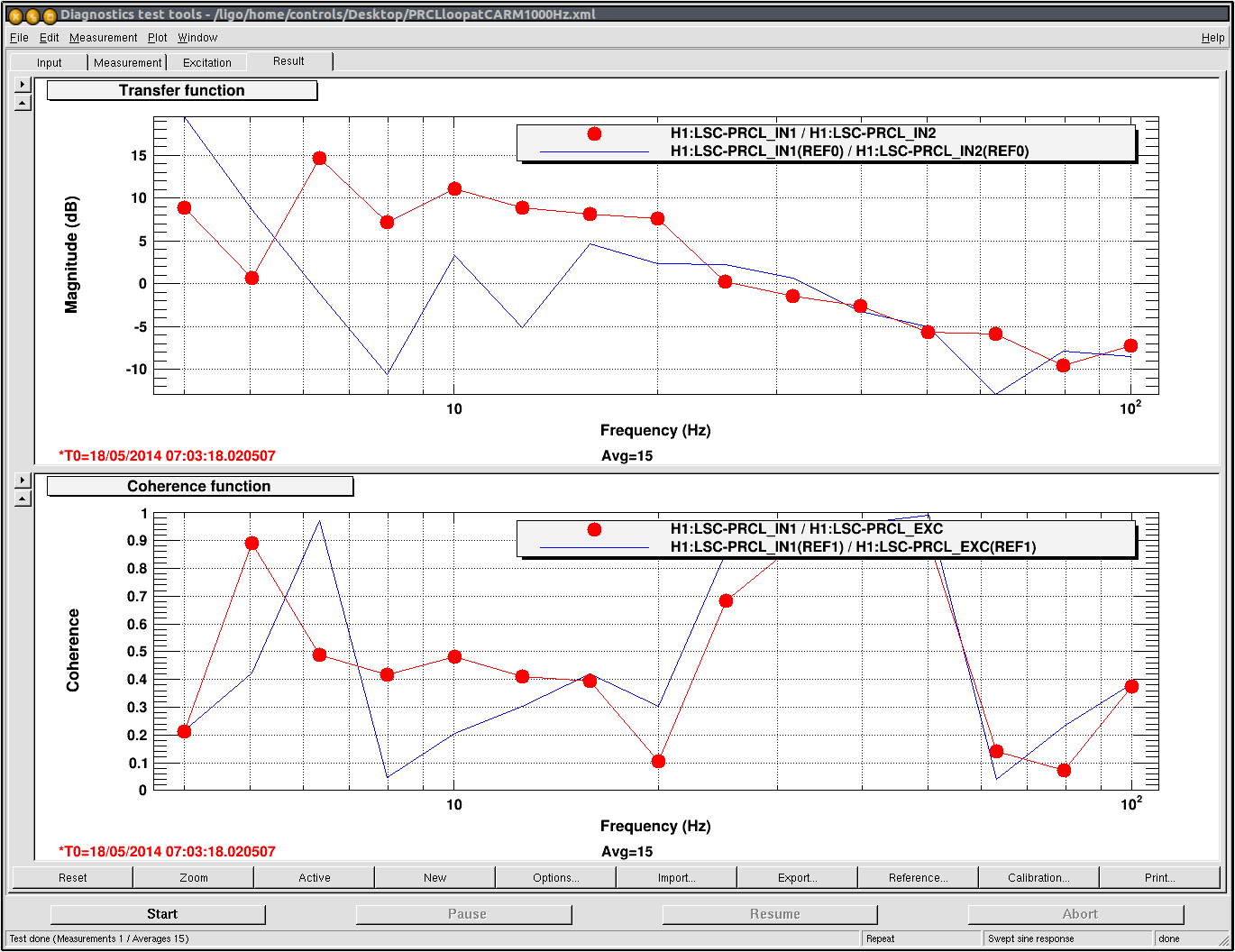

So, we just tuned the REFL 45 phase by monitored the MICH OL TF and the REFL 45 I/Q decoupling by looking at a PRCL line around 50 Hz.

Not a very advanced technique, but we could recover pretty easily a reasonable shape for the MICH loop and we could reduce the CARM offset.

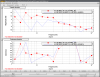

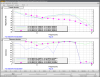

Kiwamu will post some plots with the MICH OL TF; here are some numbers for the REFL 45 phase:

Without the arms: 144 dg

1 kHz --- 900 Hz CARM offset: 172 dg

800 Hz --- 700 Hz CARM offset: 180 dg

We were happy and ready to do the transition to 3f, but another seismic event like the previous one made the lock of the Y arm more difficult.

We are still debating if we should go home or not...