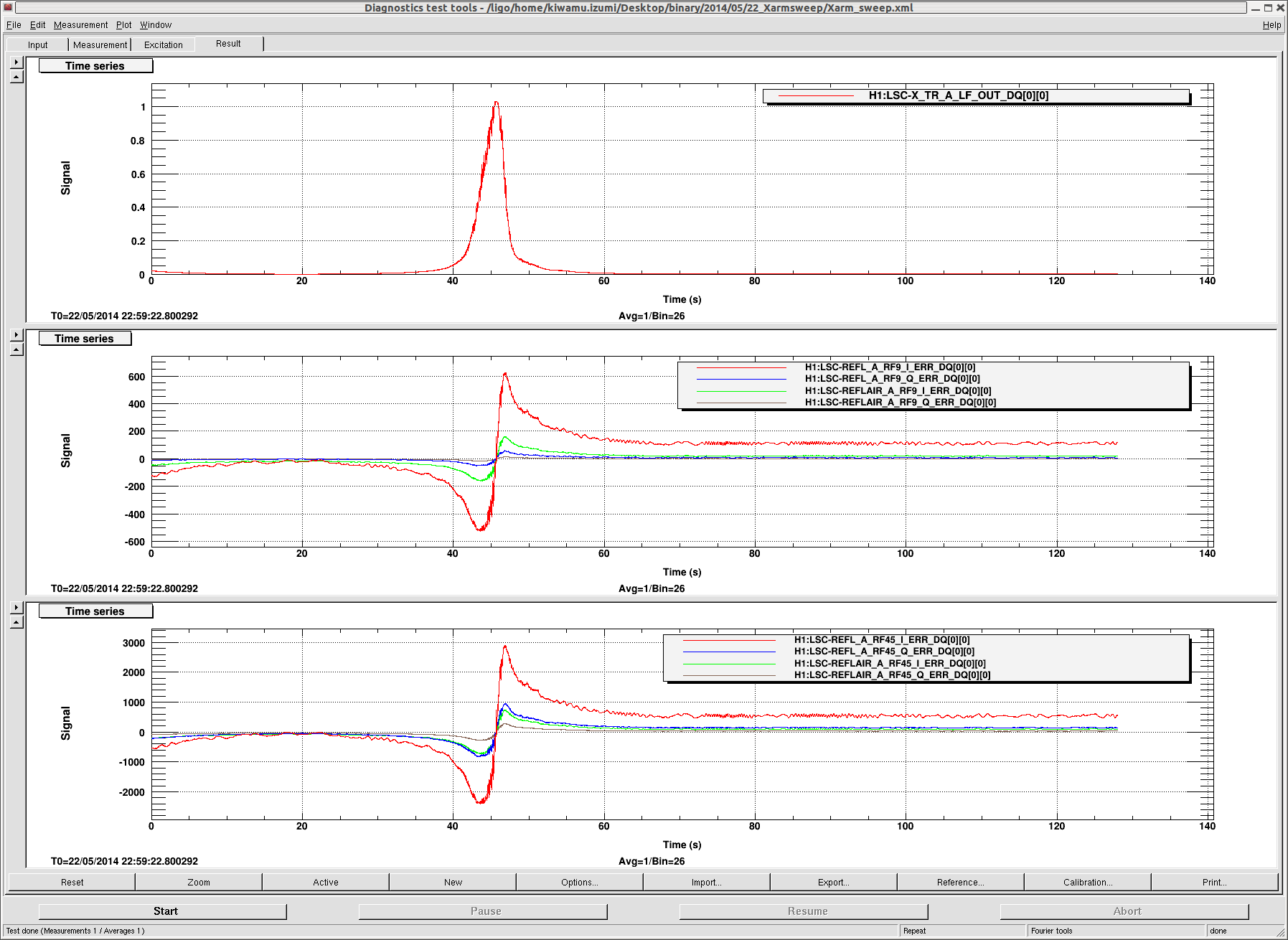

J. Kissel, A. Staley As suspected, the problem appears to be the 71 MHz local oscillator that the Y end. At the remote advice of Alexa, I increased the ALSY's "LO mon" value, H1:ALS-Y_REFL_A_DEMOD_LONOM, from 20 to 21. As soon as I did so, the arm locked up instantly, the demod error disappeared, and the guardian error message cleared. Even more strange, the monitor value, H1:ALS-Y_REFL_A_DEMOD_LOMON is still *above* 21, so the nominal must be a mean with a range not a threshold. Even more strange than that, if I decrease the nominal value back down to 20, the arm remains locked. DAH! I guess I have plenty more to learn on this system. Anyways, the 71 MHz power supply still claims that its power supply voltages are too low, and its output monitor, H1:ISC-RF_Y_AMP71M_OUTPUTMON, says the power is 51 [dBm]. We should fix this (if its actually broken) on Tuesday. We should also put in some effort to making the guardian subsystem messages more clear. For now I'll continue with the LO nominal set to 21 [??]. (Though I'm surprised that Stefan's state machine doesn't prevent me from doing this...) Also, I attach the MEDM screen chain one has to follow to get to this information. SITEMAP > ALS tab > ALS Overview > Y Arm PDH [little black words in a silver background box] > 71MHz RF Amp I'm leaving both the X and Y arm locked and well aligned. And will shoot for the moon again tomorrow.

Doesn't make a lot of sense to me. The PDH LO is driven the 24.4MHz source. The 71MHz is used by the VCO. It looks like the monitor cable is unplugged, or maybe the 71MHz source is down? Check the RF monitors of the VCO. Documentation actually exists. RF monitors are part of the Beckhoff system. The tolerance is ±1dBm. A 1dBm variation of the PDH LO shouldn't prevent the Y-arm from locking.