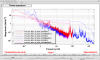

Last we we installed some lower frequency blend filters into the rX and rY filter banks for stage 1 and 2 of the ETMX and ITMX ISIs. This was motivated by seeing a lot of coherence between stage 1 and 2 rY motion to the optical lever pitch signal around the first suspension mode (COH >0.8 from 0.2-0.6Hz more or less).

I've taken some performance plots for these controllers (all data was taken with level 3 controllers)

Units are nm/rHz or nRad/rtHz

I tested three states, 11 DOFs using TCrappy, Stage 1 rZ using Start, - Black and Orange dotted lines T240 and Gs13 signals

9 DOFS using TCrappy, Stage 1 and 2 rY using TBetter (lower blend frequency see plot) Stage 1 rZ using Start Cyab line T240s

10 DOFs using TCrappy, Stage 1 and 2 rY using TBetter Blue, Brown and Pinks curves, T240, Gs13 and L4Cs

The interesting plots are rY which shows lots more isolation at the suspension mode, the GS13 sensor noise is ~3E-10 m/s/rHz @ 0.45Hz. Which says that we are way into the sensor noise (today was a windless sunday), so maybe we can relax the blend a bit and knock down the microseism a bit., I'm a little suspicious that i made a calculation error here

The X plot shows some increase below 0,2Hz

The rZ plot shows a fair amount of microseism which is being increase by the Tcrappy blends, we should try a more aggressive blend for stage 1 rZ

Also ITMY does not have a good set of level 3 controller installed