[Jeff Arnaud]

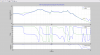

ITMY top mass pitch actuation to test mass pitch response measured by the optical lever was taken on friday afternoon using a "colored" white noise excitation. This method works fine for measuring main couplings (P2P for eg), but hasn't been tested for the cross couplings (L2P). The reason the white noise is filtered through a low pass is because, when increasing the overall amplitude of the signal, it would saturate the DAC at higher frequencies (because of the antiAcqFilter in the coilout filter bank which has a zero at 1Hz and a pole at 30Hz).

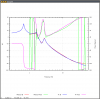

The measurement was fairly quick (less than one hour) and gives good coherence until 3Hz. I attached a comparison of the measurement against the "wirerehang" model.

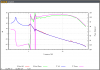

Note that the model and the measurement are very well matching until 2 Hz, but slightly differs (~2%) for the 3rd and 4th pitch mode (2.5 and 2.8Hz). From 3Hz, the signal is two noisy to make any comparison. I added (from Jeff's advise) the top to top pitch TF (2nd attachement), to see how the pitch3 and pitch4 differs at the top level.

Note also that the sign of the oplev phase signal had to be flipped to match the model, so Pitch oplev sign convention differs than SUS.

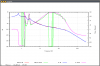

The next step is to do the same comparison for L2P, then fit the measured (or modeled?) TFs in order to create the L2P decoupling filter.

Attached is the measured vs modeled Top mass Length to test mass Pitch transfer function. There is an extra zero in the measured TF at 0.18Hz, which is below the first QUAD resonnance (0.44Hz). I checked the same TF taken on ETMX, and it doesn't have the same feature, so it's unclear where it comes from.