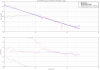

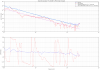

They weren't empty but they were wrong. The IPS raw signals only became useful Monday after we finished the final alignments after the Actuator connection. So if you care (likely not) about the ETM HEPI position before now (0955pdt) you'll have to look at the local coordinates. Now you can look at the cartesian values for positions. Remember, I zero'd (<50 counts, 655cts.0.001" or 38.8nm/ct) Monday. The raw IPS are all running under 300cts now (HEPI is still unlocked) but the ACB weight decreased slightly yesterday and I'm not surprised to see a little drift as well. The cartesian are all running under 10um or urad and most much less. The nominal position for control will be zero.

Your data is saved and ETMX is misaligned now.