Today we have a different type of interesting seismic time, the low frequency ground motion due to the earth quake has subsided, but we still have microseism well above the 90th percentile (the wind has also died down). While the microseism is high, it seems like these might be conditions we want to be able to ride out in the long run. ETMX and ITMX are both isolated with Tcrappy (no sensor correction), both have pitch fluctuations of about 0.3urad, but yaw fluctuations of more than 1 urad. Right now it is UTC 1:28.

A screenshot of the ground motion and Op Levs are attached, the .xml file which also includes SEI sensors is available here

Is this ground motion just too much for us to ride out, or is there a configuration for the ISIs that would be better under these conditions?

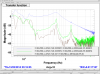

Though they haven't been confirmed to work well under these conditions, you should try switching to the "Start" filters (which have a high blend frequency) on ST2, and switching on some modest ST1 to ST2 sensor correction. You lose performance at 1 [Hz] but improve microseism by a factor of 10ish. You can see the variation in performance from LHO aLOG 10728, specifically, the attachment. Note, we can also try the T750 [mHz] blend filters on ST1, but I don't have a good aLOG of their performance. My guess is that Seb didn't have time to characterize this configuration. #movetheblendUP