Results of my visit to LHO this week for system identification of the ETMY.

MOTIVATION:

Make better models for each particular suspension to aid control design and noise predictions.

The measured frequencies of the resonances are the most reliable data we have because they are not subject to errors in the sensors or actuators. There are also numerous resonances available for measurement, which can be used to adjust the model.

SETUP:

Resonance measurements were collected on ETMY main chain while on the test stand in the follow configuration with the following methods:

* full quad - top mass to top mass transfer functions using the OSEMs. This data was measured prior to my visit this week.

* triple hang - with the main chain top mass, reaction chain UIM and PUM masses locked on stops, spectra of the lower three main chain stages were measured with the UIM and PUM OSEMs and an optical lever on the test mass. No excitation is needed since the wind from the fans is more than enough. The process of locking the masses also misaligns the UIM and PUM OSEMs sufficiently that they are sensitive to vertical, roll, and transverse displacements of the stages. This allows us to measure more resonances with these OSEMs then we otherwise would. The optical lever isn't sensitive to any resonances the OSEMs miss, but it does add redundancy to help identify a forest of high Q pendulum resonances from spectra that include a lot of similarly shaped artifacts.

* double hang - with the main chain UIM and reaction chain PUM locked on stops, spectra of the main chain lower two stages were measured with the PUM OSEMs. In this case the optical lever would not stay in range, so the data is just the 4 PUM OSEMs.

* single hang - with the PUM on the teflon line stops, the test mass modes were measured with optically. This data was measured prior to my visit.

SUMMARY:

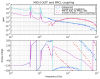

The data encompasses 56 resonance frequencies: 22 free quad, 16 triple hang, 12 double hang, and 6 single hang. See the attached plots and the summary of parameter changes below. In the attachment the black curves are the measured data, the blue the original model, and the red the new model. Pages 1-6 of the attachement show the diagonal top mass to top mass transfer functions. Pages 7-8 show L-P coupling and 9-10 T-R coupling. 11-13 are the frequencies of the triple, double, and single hangs respectively. 14 plots the mode frequency percent errors before the fit and 15 shows the same after the fit. The final page shows the convergence of the total error, where the error is calculated as

sum( [(measure mode - modeled mode)/(measured mode)]^2 )

The algorithm for fitting the data is Gauss-Newton, an approximation of Newton's method. The fitting code is on the svn at .../sus/trunk/QUAD/Common/MatlabTools/QuadModel_Fit/QuadPend_QuassNewton_fit_v2_H1ETMY.m.

Change in parameters from original model with the estimated convergence errors:

---------------------------------------

Inx (top mass roll inertia) : -1.0926 +- 2.6994 %

Iny (top mass pitch inertia) : 3.1636 +- 3.4396 %

Inz (top mass yaw inertia) : -0.86123 +- 0.65824 %

I1x (UIM roll inertia) : 3.9571 +- 0.77982 %

I1y (UIM pitch inertia) : 12.2729 +- 2.5078 %

I1z (UIM yaw inertia) : -0.10972 +- 0.55984 %

I2x (PUM roll inertia) : -2.9587 +- 0.85205 %

I2y (PUM pitch inertia) : 8.4597 +- 0.6904 %

I2z (PUM yaw inertia) : 0.011768 +- 0.3983 %

I3x (test mass roll inertia) : 2.2009 +- 0.77109 %

I3y (test mass pitch inertia) : -8.8738 +- 0.79819 %

I3z (test mass yaw inertia) : 0.44122 +- 0.5629 %

l2 (PUM wire loop length) : 8.6866 +- 1.1464 mm

l3 (fiber length) : 22.1269 +- 2.6176 mm

kcn (top stage spring stiffness) : 1.0719 +- 2.166 %

kc1 (top mass spring stiffness) : 1.0935 +- 0.68178 %

kc2 (UIM spring stiffness) : 2.2795 +- 0.39067 %

kw3 (fiber bounce stiffness) : 9.4286 +- 0.4488 %

dn (top mass blade tip height) : -0.20928 +- 0.303 mm

d1 (UIM blade tip height) : 1.8131 +- 0.56431 mm

d4 (effective fiber flexure at test mass): -4.8356 +- 0.23685 mm

---------------------------------------

DISCUSSION:

The fit of the original model was fairly descent already, except for pitch. The fit of the new model to this data is even better, especially for pitch. The worst mode frequency error decreases from 8.2% to 1.3%. Interestingly, even though only resonance frequencies were included in the fit, the shapes of the transfer functions (including zeros) all match well also. This goes for the cross coupling measurements as well. Note, the length to pitch measurement does not match the pitch to length. These should in theory be identical. Mismatches indicate measurement problems. Length to pitch has some low frequency notches that don't exist in pitch to length. Judging by the models (both before and after), I think it is likely that pitch to length is the more accurate measurement up to 4 Hz. I don't think we can believe either beyond 4 Hz. After the fit, the worst error in mode frequency corresponds to the first roll mode for both the free quad case and the triple hang case.

The inclusion of the extra resonance frequencies made a huge difference in the ability of the model to converge. In this case, a total of 21 parameters were floated. Normally, only a few at a time can be floated using just top mass data.

Many of the parameter changes produced by the fitting code seem quite reasonable. Some that are beyond what you would expect are the lengths of the fibers and the PUM wire loop. These changed by 22 mm and almost 9 mm respectively. Since the mass values are known, the only way to fit all 10 measured longitudinal modes is to adjust the wire lengths. This was achievable by floating both these wire/fiber lengths. I noticed that the default value in the original model for the PUM wire loop has the following comment: "% wire hang value - Mark Barton, 11/22/2011". I wonder if the entered value is no longer correct since the quad is not in the 'wire hang' configuration anymore. Regarding the fibers, the effective flexure length is rather complicated due to the geometry of the fibers. Perhaps some other error, like in fiber radius can mimic this. Note, the bounce mode stiffness moved by 9%.

The d4 change is also large. It is very likely this value is not physical because this parameter has significant degeneracy with both d3 and d2. Thus, the decrease of 5 mm could be spread out between all 3. d2 also has twice the sensitivity, so a small shift there can take up a fair bit of this 5 mm on its own. These degeneracies prevent the fitting code from floating these parameters simultaneously, so you simple have to pick one. d2 is sort of awkward because it is degenerate enough that it is difficult to float with either d3 or d4, but different enough that floating it instead of d3 or d4 yields different results.

DISCLAIMER:

As usual, the choice of parameters to float was made by experience and intuition. These parameter changes are not necessarily representative of reality. Though, with a fit that matches all 56 measurements to the 1% level, you might start to think that this thing is converging within some distance of reality.

COMPARISON WITH FUTURE MEASUREMENTS:

We should see how this new model holds up against L-P measurements at other stages and between stages.

NOTES:

The high frequency vertical and bounce modes were visible on the single hang and double hang measurements, but not the triple and free quad. If they were visible in all there would be 60 measured resonances. However, these modes are virtually the same from double hang to triple hang to free quad because they involve primarily displacement between the bottom two masses. Thus, the loss of information is negligible. In fact, we might be better off not including these extra bounce modes in case they emphasize bottom mass parameters over the upper masses since the same information would essentially be repeated 3 times.

h1broadcaster was very slow to come back from the DAQ restart. We manually restarted it and it eventually started. No errors were seen to explain this.